Understanding Idler Pulleys: Your Ultimate Guide

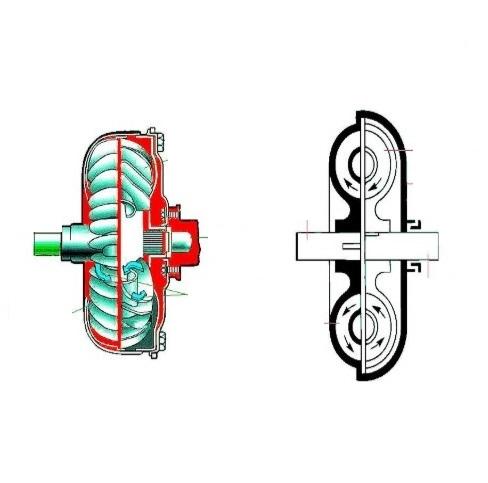

Idler pulleys are crucial components in various mechanical systems, especially in automotive and industrial applications. They serve to guide, tension, or route belts within engines, machinery, and other equipment. At our company, we pride ourselves on manufacturing high-quality idler pulleys designed for durability, efficiency, and optimal performance. This guide provides an in-depth look at our product specifications, features, and answers to frequently asked questions, helping you make an informed decision for your needs.

Key Features of Our Idler Pulleys

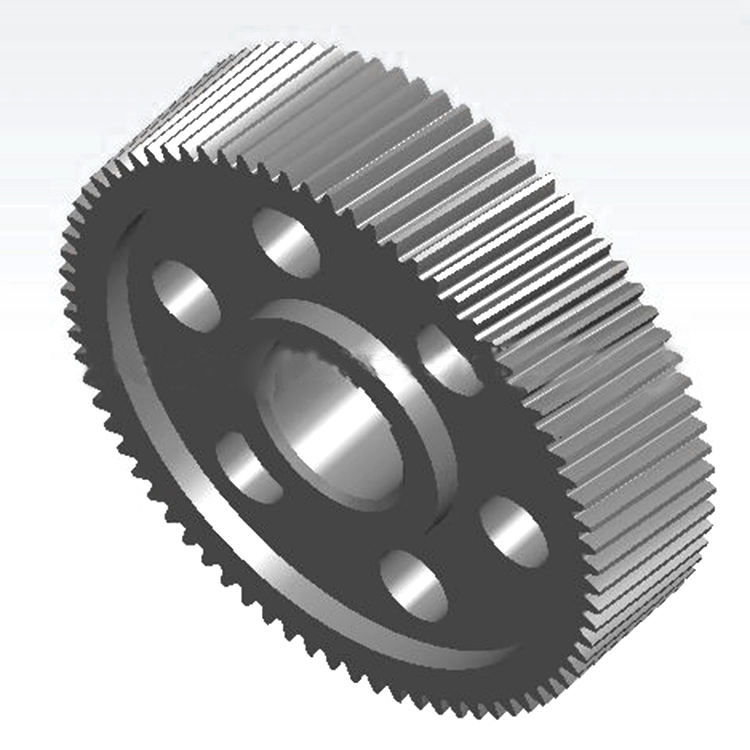

- Durable Construction: Made from premium materials such as reinforced steel or high-grade polymers to withstand high stress and temperatures.

- Smooth Operation: Equipped with precision bearings that ensure minimal friction and noise, extending the life of your belt system.

- Corrosion Resistance: Treated with anti-corrosion coatings to perform reliably in harsh environments, including exposure to moisture and chemicals.

- Easy Installation: Designed with standardized mounting points for quick and hassle-free replacement or installation.

- Versatility: Compatible with a wide range of belt types and applications, from automotive serpentine belts to industrial conveyor systems.

Detailed Product Parameters

Our idler pulleys come in various sizes and specifications to meet diverse requirements. Below is a table summarizing the key parameters for our standard product line.

| Model Number |

Outer Diameter (mm) |

Bore Size (mm) |

Belt Width Compatibility (mm) |

Material |

Max RPM |

Load Capacity (kg) |

| IP-100 |

100 |

15 |

10-12 |

Steel with Coating |

6000 |

50 |

| IP-150 |

150 |

20 |

15-18 |

Polymer Composite |

5000 |

40 |

| IP-200 |

200 |

25 |

20-25 |

Stainless Steel |

4500 |

70 |

| IP-250 |

250 |

30 |

25-30 |

Aluminum Alloy |

4000 |

60 |

For custom specifications, please contact our support team with your specific requirements, and we can tailor products to fit unique applications.

Frequently Asked Questions (FAQ) About Idler Pulleys

What is the primary function of an idler pulley?

An idler pulley is used to guide and maintain tension on a belt in a system, ensuring proper alignment and preventing slippage. It does not transmit power but supports the belt's path for efficient operation.

How often should I replace an idler pulley?

Replacement intervals depend on usage conditions, but generally, inspect idler pulleys every 50,000 to 100,000 miles in automotive applications or during routine maintenance checks. Signs of wear, such as noise, wobbling, or visible damage, indicate the need for replacement.

Can I use any idler pulley for my vehicle or machine?

No, it's essential to use a pulley that matches the specifications of your system, including size, bore diameter, and material compatibility. Using an incorrect pulley can lead to belt failure, reduced efficiency, or damage to other components.

What materials are best for idler pulleys in high-temperature environments?

For high-temperature applications, such as in engines, materials like steel with heat-resistant coatings or specialized polymers are recommended. These materials can withstand temperatures up to 150°C or higher without degrading.

How do I install an idler pulley properly?

First, ensure the system is off and cool. Remove the old pulley by loosening the mounting bolt, then align the new pulley with the bracket, making sure it rotates freely. Tighten the bolt to the manufacturer's specified torque, and check for proper belt tension and alignment before operation.

What are common signs of a failing idler pulley?

Common indicators include squeaking or grinding noises, visible wear on the pulley surface, belt misalignment, or excessive vibration. If you notice any of these, inspect and replace the pulley promptly to avoid further issues.

Are there maintenance tips for extending the life of an idler pulley?

Yes, regularly clean the pulley and surrounding area to prevent debris buildup, check for proper belt tension, and lubricate bearings if they are not sealed. Avoid over-tensioning belts, as this can increase wear on the pulley.

Can idler pulleys be used in both automotive and industrial settings?

Absolutely. Idler pulleys are versatile and used in various applications, including automotive engines, industrial machinery, agricultural equipment, and HVAC systems. Ensure the pulley is rated for the specific environment and load requirements.

What is the difference between an idler pulley and a tensioner pulley?

An idler pulley primarily guides the belt without adjusting tension, while a tensioner pulley includes a mechanism to automatically maintain or adjust belt tension. Both are important but serve slightly different functions in a system.

Do you offer custom idler pulleys for unique applications?

Yes, we provide custom manufacturing services. Share your specifications, such as dimensions, materials, and operating conditions, and our engineering team will develop a solution tailored to your needs.