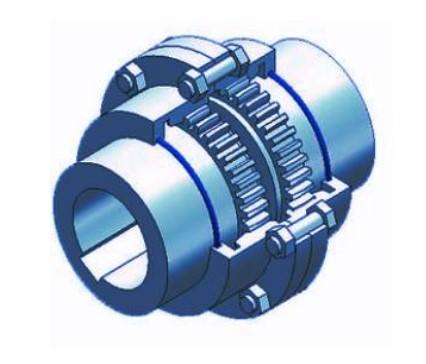

MH Couplings: The Ultimate Solution for Industrial Connectivity

MH Couplings are engineered to deliver superior performance in demanding industrial environments. With decades of innovation and expertise, our couplings ensure reliable power transmission, reduced downtime, and enhanced operational efficiency. This comprehensive guide covers everything you need to know about MH Couplings, including detailed product specifications, FAQs, and applications.

Product Overview

MH Couplings are designed for a wide range of industries, including manufacturing, automotive, aerospace, and heavy machinery. They offer exceptional durability, flexibility, and precision, making them ideal for high-torque and high-speed applications. Our products are manufactured using premium materials and undergo rigorous testing to meet international standards.

Key Features of MH Couplings

- High torque capacity for robust performance

- Excellent misalignment compensation (angular, parallel, and axial)

- Low maintenance requirements due to minimal wear

- Corrosion-resistant materials for longevity

- Easy installation and alignment processes

- Customizable options for specific applications

Detailed Product Parameters

Below is a table summarizing the technical specifications for our standard MH Coupling series. These parameters help in selecting the right coupling for your needs.

| Model |

Bore Diameter (mm) |

Max Torque (Nm) |

Max Speed (RPM) |

Weight (kg) |

Material |

| MH-100 |

10-25 |

50 |

10,000 |

0.5 |

Stainless Steel |

| MH-200 |

20-40 |

150 |

8,000 |

1.2 |

Aluminum Alloy |

| MH-300 |

30-60 |

300 |

6,000 |

2.5 |

Carbon Steel |

| MH-400 |

40-80 |

500 |

5,000 |

4.0 |

Stainless Steel |

| MH-500 |

50-100 |

800 |

4,000 |

6.5 |

Titanium Alloy |

Applications of MH Couplings

MH Couplings are versatile and suitable for various applications:

- Conveyor systems in logistics and warehouses

- Pump and compressor drives in oil and gas industries

- Robotics and automation in manufacturing

- Power transmission in agricultural machinery

- Marine propulsion systems

Installation and Maintenance Tips

Proper installation and maintenance are crucial for optimal performance. Follow these guidelines:

- Ensure shafts are clean and free of burrs before installation.

- Align couplings within specified tolerances to prevent premature wear.

- Lubricate moving parts as per manufacturer recommendations.

- Regularly inspect for signs of wear, such as vibration or noise.

- Replace couplings if any damage is detected to avoid system failures.

Frequently Asked Questions (FAQ)

What is the typical lifespan of an MH Coupling?

The lifespan depends on usage conditions, but with proper maintenance, MH Couplings can last over 10 years in standard industrial environments. Factors like load, speed, and alignment affect durability.

Can MH Couplings handle high-temperature applications?

Yes, certain models made from materials like stainless steel or titanium alloy can operate in temperatures up to 400°C. Always check the product specifications for temperature ratings.

Are MH Couplings suitable for reverse rotation?

Absolutely. MH Couplings are designed to handle bidirectional rotation without any loss in performance or efficiency.

How do I select the right MH Coupling for my machine?

Consider parameters such as torque requirements, shaft sizes, speed, and environmental conditions. Refer to our product table or consult with our technical team for personalized recommendations.

Do MH Couplings require special tools for installation?

No, most MH Couplings are designed for easy installation with standard tools. However, always follow the installation guide to ensure proper fit and function.

What warranties do you offer on MH Couplings?

We provide a standard warranty of 2 years from the date of purchase, covering defects in materials and workmanship. Extended warranties may be available for specific products.

Can I get custom-designed MH Couplings for unique applications?

Yes, we offer customization services. Contact our engineering team with your requirements, and we can develop couplings tailored to your specific needs.

How do MH Couplings compare to other brands in terms of cost?

MH Couplings are competitively priced, offering excellent value due to their durability and low maintenance. While initial costs might be higher than some alternatives, the long-term savings in reduced downtime and replacements make them a cost-effective choice.

What industries commonly use MH Couplings?

They are widely used in automotive, aerospace, manufacturing, energy, and marine industries, among others, due to their reliability and versatility.

Is technical support available for MH Couplings?

Yes, we provide comprehensive technical support, including installation guidance, troubleshooting, and maintenance advice. Reach out to our support team via email or phone.