Angular Gearbox: High-Precision Power Transmission Solutions

Angular gearboxes are essential components in industrial machinery, providing efficient torque transmission between non-parallel shafts, typically at a 90-degree angle. Our Angular Gearbox series is engineered for durability, precision, and versatility, making it ideal for applications in robotics, automotive systems, conveyor belts, and heavy machinery. With decades of innovation, we offer products that meet rigorous international standards, ensuring reliable performance in demanding environments.

Key Product Parameters

Our Angular Gearboxes come in various sizes and configurations to suit diverse needs. Below is a detailed list of standard parameters:

- Gear Ratio: Available from 1:1 to 100:1, allowing for precise speed control.

- Input Speed: Up to 3000 RPM, compatible with high-speed motors.

- Torque Capacity: Ranges from 10 Nm to 2000 Nm, handling light to heavy loads.

- Efficiency: Typically 95-98%, minimizing energy loss.

- Mounting Options: Foot-mounted, flange-mounted, or shaft-mounted designs.

- Material: Housing made from high-strength cast iron or aluminum alloy; gears are hardened steel for longevity.

- Lubrication: Pre-filled with synthetic oil; maintenance-free for up to 20,000 hours.

- Operating Temperature: -20°C to 120°C, suitable for extreme conditions.

- Noise Level: Below 70 dB, ensuring quiet operation.

- Protection Class: IP65 or higher, resistant to dust and water ingress.

Detailed Specifications Table

For a comprehensive overview, refer to the table below showcasing our product range:

| Model |

Gear Ratio |

Max Torque (Nm) |

Input Speed (RPM) |

Weight (kg) |

Efficiency (%) |

| AGB-100 |

1:1 to 10:1 |

10-100 |

3000 |

2.5 |

98 |

| AGB-200 |

5:1 to 50:1 |

50-500 |

2500 |

5.0 |

97 |

| AGB-300 |

10:1 to 100:1 |

200-2000 |

2000 |

10.0 |

96 |

| AGB-400 |

20:1 to 80:1 |

1000-1500 |

1800 |

15.0 |

95 |

Applications of Angular Gearbox

Angular gearboxes are widely used in industries requiring precise angular power transmission. Common applications include:

- Robotics: For joint movements and actuator systems.

- Automotive: In steering mechanisms and drive systems.

- Conveyor Systems: To redirect motion in packaging and material handling.

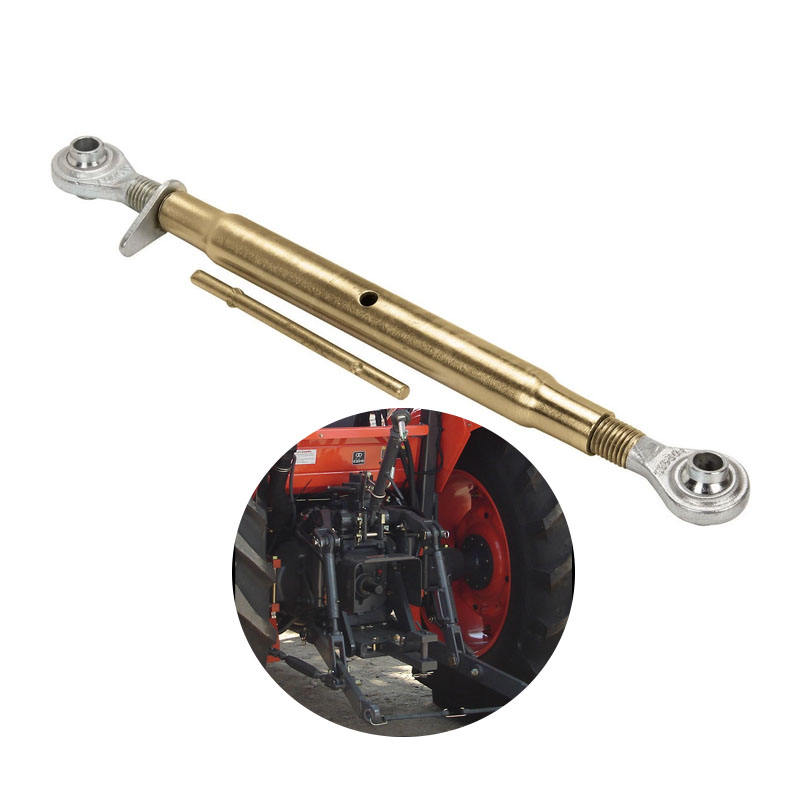

- Agricultural Machinery: In tractors and harvesters for efficient power transfer.

- Industrial Mixers: Ensuring smooth operation in chemical and food processing.

FAQs About Angular Gearbox

Here are some frequently asked questions to help you understand our products better:

What is an angular gearbox used for?

An angular gearbox is used to transmit power between shafts that are not parallel, typically at a 90-degree angle, common in machinery where space constraints or design requirements demand non-linear power flow, such as in robotics or automotive applications.

How do I choose the right angular gearbox for my application?

Select based on parameters like gear ratio, torque requirements, input speed, and environmental conditions. Consider the load type, mounting options, and efficiency. Our product table and specifications list can guide you; for custom needs, consult our engineering team.

What maintenance does an angular gearbox require?

Our gearboxes are designed for low maintenance, with pre-lubrication lasting up to 20,000 hours. Regular inspections for wear, noise, or leaks are recommended. In harsh environments, check lubrication levels annually and replace seals if necessary.

Can angular gearboxes handle high torque applications?

Yes, models like AGB-300 and AGB-400 support torque up to 2000 Nm, making them suitable for heavy-duty applications. Ensure proper alignment and mounting to prevent overload and extend lifespan.

Are these gearboxes compatible with different motor types?

Absolutely. They work with various motors, including AC, DC, and servo motors. The input shaft design accommodates standard couplings; provide motor specifications for seamless integration.

What is the typical lifespan of an angular gearbox?

With proper use and maintenance, our gearboxes can last over 10 years. Factors like load intensity, operating conditions, and adherence to maintenance schedules influence longevity.

Do you offer custom angular gearbox solutions?

Yes, we provide customized designs tailored to specific requirements, such as unique gear ratios, materials, or mounting configurations. Contact our support team with your specs for a quote.

How does temperature affect angular gearbox performance?

Extreme temperatures can impact lubrication and material expansion. Our gearboxes are rated for -20°C to 120°C, but in超出范围 conditions, use appropriate lubricants or cooling systems to maintain efficiency.

What safety features are included?

Standard features include overload protection, hardened gears for shock resistance, and IP65 protection against dust and water. Some models have additional safety locks or thermal sensors.

Where can I find installation guidelines?

Installation manuals are available on our website or upon purchase. Key steps include ensuring shaft alignment, secure mounting, and proper lubrication. Follow torque specifications for bolts to avoid damage.