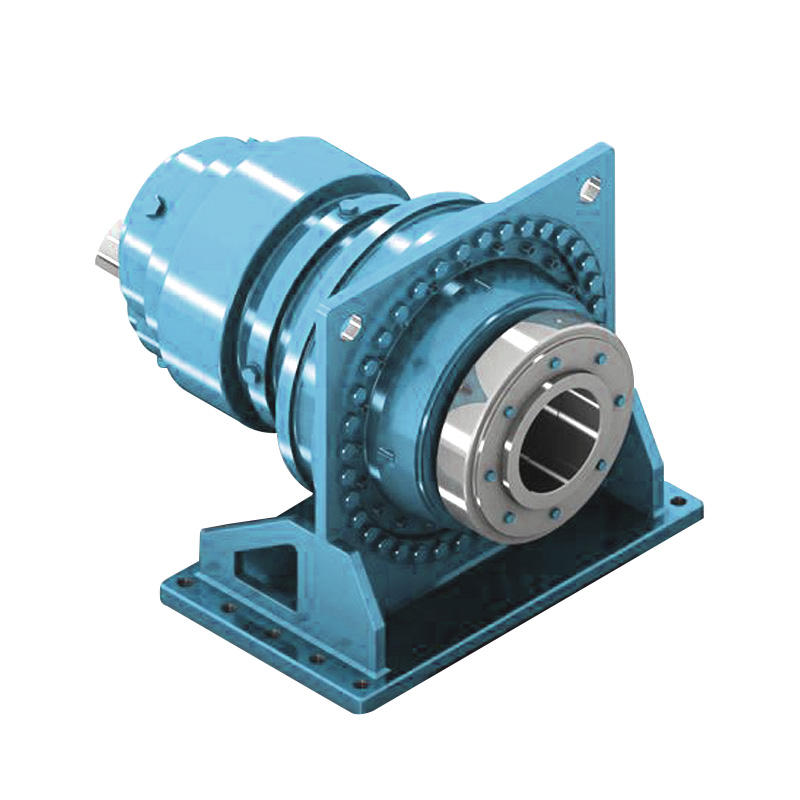

What is a Planetary Gearbox?

A planetary gearbox, also known as an epicyclic gearbox, is a high-precision gear system characterized by its compact design, high torque density, and exceptional efficiency. It consists of a central sun gear, planet gears that rotate around the sun gear, and a ring gear that encloses the planet gears. This configuration allows for multiple gear ratios and smooth power transmission, making it ideal for applications requiring high torque in a limited space, such as robotics, automotive systems, industrial machinery, and aerospace equipment.

Key Features and Benefits

- High Torque Density: Delivers more torque per unit volume compared to other gear types.

- Compact and Lightweight: Ideal for space-constrained applications.

- High Efficiency: Minimal energy loss due to balanced load distribution among planet gears.

- Low Backlash: Precision manufacturing ensures minimal play, suitable for high-accuracy systems.

- Durability: Robust construction with high-quality materials for long service life.

- Versatility: Available in various sizes, ratios, and configurations to meet diverse needs.

Technical Specifications

Our planetary gearboxes are engineered to meet the highest standards of performance and reliability. Below is a detailed table of product parameters for our standard series.

| Model |

Gear Ratio |

Rated Torque (Nm) |

Max Torque (Nm) |

Efficiency (%) |

Backlash (arcmin) |

Weight (kg) |

Input Speed (rpm) |

| PG-42 |

3:1 to 100:1 |

40 |

80 |

95 |

<5 |

1.2 |

6000 |

| PG-60 |

5:1 to 150:1 |

100 |

200 |

96 |

<4 |

2.5 |

5000 |

| PG-90 |

10:1 to 200:1 |

250 |

500 |

97 |

<3 |

5.0 |

4000 |

| PG-120 |

20:1 to 300:1 |

500 |

1000 |

98 |

<2 |

8.5 |

3000 |

Applications of Planetary Gearboxes

- Robotics: Used in robotic arms and joints for precise movement and high torque.

- Automotive: Employed in electric vehicles for transmission systems and power steering.

- Industrial Machinery: Integral in conveyors, mixers, and packaging equipment.

- Aerospace: Utilized in satellite mechanisms and aircraft control systems.

- Renewable Energy: Applied in wind turbines and solar tracking systems.

Planetary Gearbox FAQ

What is the main advantage of a planetary gearbox?

The main advantage is its high torque density and compact size, allowing for efficient power transmission in limited spaces with minimal weight.

How do I select the right gear ratio for my application?

Consider the required output speed and torque. Lower ratios provide higher speed and lower torque, while higher ratios offer lower speed and higher torque. Consult our technical team for specific needs.

What maintenance is required for a planetary gearbox?

Regular lubrication and inspection for wear are essential. Most models are designed for low maintenance, but follow the manufacturer's guidelines for lubrication intervals and environmental conditions.

Can planetary gearboxes handle high shock loads?

Yes, they are built to distribute loads evenly across multiple planet gears, making them resilient to shock and overload conditions, but always operate within specified torque limits.

Are custom configurations available?

Absolutely. We offer custom designs for unique applications, including specific ratios, materials, and mounting options. Contact us with your requirements.

What materials are used in your gearboxes?

We use high-strength alloy steels for gears, hardened and ground for durability, and aluminum or cast iron for housings, depending on the model and application.

How does backlash affect performance?

Low backlash is crucial for precision applications, as it minimizes play between gears, ensuring accurate positioning and smooth operation. Our gearboxes are engineered for minimal backlash.

What is the typical lifespan of a planetary gearbox?

With proper maintenance, our gearboxes can last over 20,000 hours of operation, but this varies based on load, speed, and environmental factors.