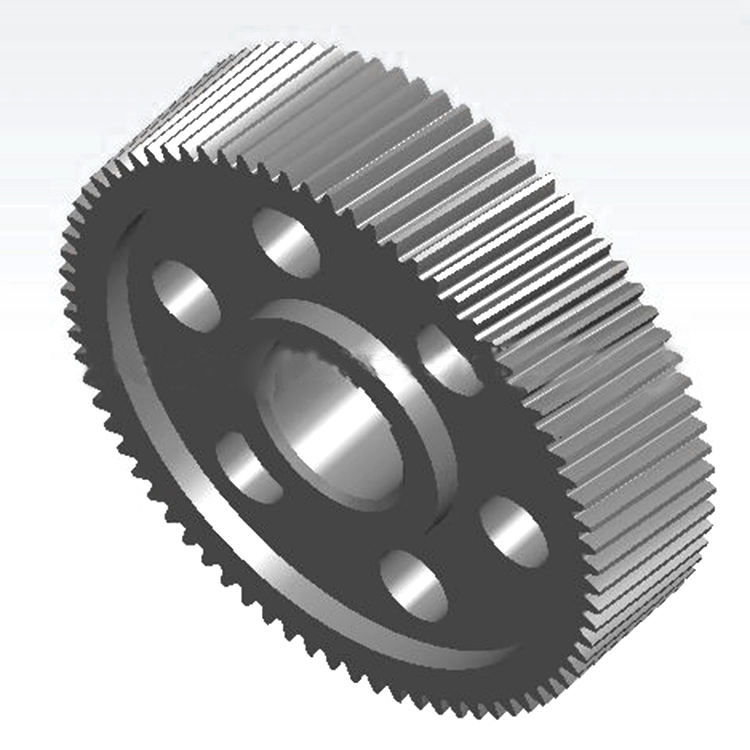

QD Bushings: Precision Power Transmission Components

QD bushings, or Quick Detachable bushings, are essential components in mechanical power transmission systems, designed for rapid installation and removal without the need for specialized tools. These bushings are widely used in various industries, including manufacturing, agriculture, and automotive, to connect shafts to hubs, sprockets, or pulleys efficiently. Their key advantage lies in the ability to facilitate easy maintenance and part replacement, reducing downtime and improving operational efficiency. With a robust design that ensures secure locking and high torque transmission, QD bushings are ideal for applications where reliability and quick serviceability are critical. This article provides an in-depth look at QD bushings, covering their features, specifications, and common questions to help you make informed decisions for your machinery needs.

Key Features of QD Bushings

QD bushings boast several standout features that make them a preferred choice in industrial settings:

- Quick Detachability: Allows for fast assembly and disassembly, saving time during maintenance or part changes.

- High Torque Capacity: Engineered to handle substantial torque loads without slipping, ensuring reliable power transmission.

- Versatility: Compatible with various shaft sizes and types, making them adaptable to different machinery setups.

- Durability: Constructed from high-strength materials like cast iron or steel, offering resistance to wear and corrosion.

- Precision Fit: Provides a tight, secure connection between the shaft and hub, minimizing vibrations and misalignment.

- Cost-Effectiveness: Reduces labor costs and downtime due to easy installation, leading to overall savings.

Product Parameters and Specifications

Below is a detailed breakdown of common QD bushing parameters, presented in a table for clarity. These specifications are based on standard industry sizes and may vary slightly by manufacturer. Always refer to product datasheets for exact measurements.

| Parameter |

Description |

Typical Range |

Units |

| Bore Diameter |

Inner diameter that fits onto the shaft |

0.5 to 6 inches |

Inches |

| Outside Diameter |

Outer diameter for hub connection |

1 to 10 inches |

Inches |

| Length |

Overall length of the bushing |

1 to 4 inches |

Inches |

| Material |

Common materials used in construction |

Cast Iron, Steel, Alloy |

- |

| Torque Rating |

Maximum torque the bushing can transmit |

50 to 2000 lb-ft |

Pound-feet |

| Weight |

Approximate weight per unit |

0.5 to 10 lbs |

Pounds |

| Operating Temperature |

Temperature range for safe operation |

-40°F to 300°F |

Degrees Fahrenheit |

| Finish |

Surface treatment for corrosion resistance |

Zinc-plated, Black Oxide |

- |

Applications of QD Bushings

QD bushings are utilized in a wide array of applications due to their adaptability and performance. Common uses include:

- Conveyor Systems: For connecting drive shafts to rollers, enabling efficient material handling.

- Agricultural Equipment: In tractors and harvesters, where quick part changes are necessary during seasons.

- Industrial Machinery: Such as pumps, compressors, and gearboxes, requiring secure shaft-hub connections.

- Automotive Systems: In power transmission setups for vehicles, enhancing maintenance ease.

- Mining Equipment: For heavy-duty applications that demand high torque and durability.

FAQ: Common Questions About QD Bushings

Here are some frequently asked questions to address common queries and provide detailed insights.

What does "QD" stand for in QD bushings?

QD stands for "Quick Detachable," referring to the design that allows for easy and tool-free installation and removal of the bushing from a shaft or hub, streamlining maintenance processes.

How do I select the right QD bushing for my application?

To choose the appropriate QD bushing, consider factors such as shaft diameter, torque requirements, operating environment (e.g., temperature and exposure to elements), and material compatibility. Measure your shaft size accurately and consult manufacturer charts to match the bore diameter. Additionally, ensure the torque rating exceeds your application's maximum load to prevent failure.

Can QD bushings be reused after removal?

Yes, QD bushings are designed for multiple uses, provided they are not damaged during disassembly or operation. Inspect for wear, cracks, or deformation before reinstallation. Proper handling and storage can extend their lifespan, but replace them if signs of excessive wear appear to maintain performance and safety.

What maintenance is required for QD bushings?

Regular maintenance involves visual inspections for wear or corrosion, cleaning to remove debris, and lubrication if specified by the manufacturer (though many are self-lubricating or require minimal lubrication). Check tightness periodically to ensure secure locking, and replace bushings if they show reduced gripping force or damage.

Are QD bushings interchangeable between brands?

While many QD bushings follow industry standards, interchangeability depends on specific dimensions and tolerances. It's recommended to use bushings from the same manufacturer or verify compatibility through datasheets. Mixing brands might lead to improper fit or reduced performance, so always cross-reference parameters before substitution.

What are the common failure modes of QD bushings?

Common failures include wear from friction, corrosion due to environmental exposure, cracking under excessive load, and loosening from vibration. To prevent these, ensure correct installation, avoid over-torquing, and use bushings suited for the operating conditions. Regular inspections can help detect early signs of failure.

Can QD bushings handle high-speed applications?

Yes, many QD bushings are rated for high-speed operations, but it depends on the design and material. Check the manufacturer's specifications for maximum RPM (revolutions per minute) ratings. For high-speed uses, select bushings with precision balancing and materials that minimize vibration, such as steel alloys.

How do I install a QD bushing properly?

Installation typically involves sliding the bushing onto the shaft, aligning it with the hub, and tightening the locking mechanism (e.g., set screws or clamping bolts) to the recommended torque using a torque wrench. Ensure the shaft and bushing are clean and free of debris. Follow the manufacturer's instructions closely to avoid misalignment or damage.

What is the difference between QD bushings and taper-lock bushings?

Both are used for secure shaft-hub connections, but QD bushings emphasize quick detachment without tools, often using a simple locking design. Taper-lock bushings rely on a tapered fit that requires tools for installation and removal, potentially offering higher torque capacity in some cases. Choose based on your need for speed versus maximum holding power.

Where can I purchase genuine QD bushings?

Genuine QD bushings can be sourced from authorized distributors, industrial suppliers, or directly from manufacturers. Ensure you buy from reputable sources to avoid counterfeit products, and always verify certifications or warranties for quality assurance.