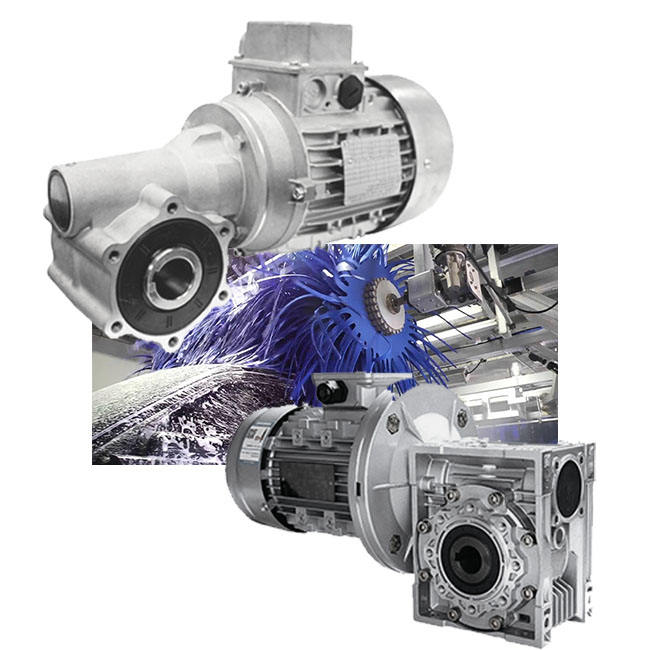

Worm gears are integral components in various mechanical systems, offering high torque transmission and compact design. At our company, we specialize in manufacturing precision worm gears tailored for industrial, automotive, and robotic applications. Our products are engineered for durability, efficiency, and smooth operation, ensuring optimal performance in demanding environments.

Key Product Parameters

Our worm gears are available in a range of specifications to meet diverse needs. Below is a detailed list of parameters:

- Material: High-grade steel, bronze, or aluminum alloys, selected for strength and wear resistance.

- Gear Ratio: Options from 5:1 to 100:1, allowing for precise speed reduction and torque multiplication.

- Efficiency: Typically between 50% and 90%, depending on the ratio and lubrication, with minimal energy loss.

- Load Capacity: Designed to handle static loads up to 5000 N and dynamic loads up to 3000 N, ensuring reliability under stress.

- Operating Temperature: Suitable for environments from -40°C to 120°C, with options for extreme conditions.

- Backlash: Controlled backlash as low as 0.05 mm for applications requiring high precision and smooth motion.

- Lubrication: Pre-lubricated with synthetic oils or greases, with recommendations for maintenance intervals to extend lifespan.

- Mounting Options: Various configurations including flange-mounted, shaft-mounted, and custom designs for easy integration.

Detailed Product Specifications Table

| Model Number |

Gear Ratio |

Max Torque (Nm) |

Efficiency (%) |

Weight (kg) |

Price Range (USD) |

| WG-101 |

10:1 |

150 |

85 |

2.5 |

$50 - $80 |

| WG-202 |

20:1 |

300 |

75 |

4.0 |

$70 - $110 |

| WG-305 |

30:1 |

500 |

70 |

6.5 |

$90 - $140 |

| WG-501 |

50:1 |

800 |

60 |

10.0 |

$120 - $180 |

FAQ Section

What are the main advantages of using worm gears?

Worm gears provide high reduction ratios in a compact size, self-locking capabilities to prevent backdriving, and smooth, quiet operation, making them ideal for applications like conveyors, lifts, and precision machinery.

How do I select the right worm gear for my application?

Consider factors such as required torque, speed ratio, operating environment, and space constraints. Our product table and parameter list can guide your selection, and our technical team is available for consultations to ensure optimal fit.

What maintenance is required for worm gears?

Regular lubrication is essential to reduce wear and heat buildup. We recommend checking lubrication levels every 500 hours of operation and replacing lubricant annually, depending on usage intensity and environmental conditions.

Can worm gears be used in high-temperature environments?

Yes, our worm gears are designed with materials and lubricants that withstand temperatures up to 120°C. For higher temperatures, special alloys and high-temperature lubricants can be custom-ordered to meet specific needs.

What is the typical lifespan of a worm gear?

With proper maintenance, our worm gears can last over 10,000 hours of operation. Factors such as load, speed, and lubrication frequency influence longevity, but our products are built for durability and long-term performance.

Are custom worm gears available?

Absolutely. We offer custom design services to tailor worm gears to unique specifications, including unusual ratios, materials, or mounting options. Contact our engineering department for a quote and design assistance.

How does backlash affect worm gear performance?

Backlash refers to the slight movement between gears when direction changes. Low backlash is crucial for precision applications to avoid positional errors. Our gears are manufactured to minimize backlash, with options as low as 0.05 mm for high-accuracy needs.

What industries commonly use worm gears?

Worm gears are widely used in automotive systems for steering mechanisms, industrial machinery for conveyor belts, robotics for joint actuation, and aerospace for control systems, due to their reliability and efficiency in torque transmission.