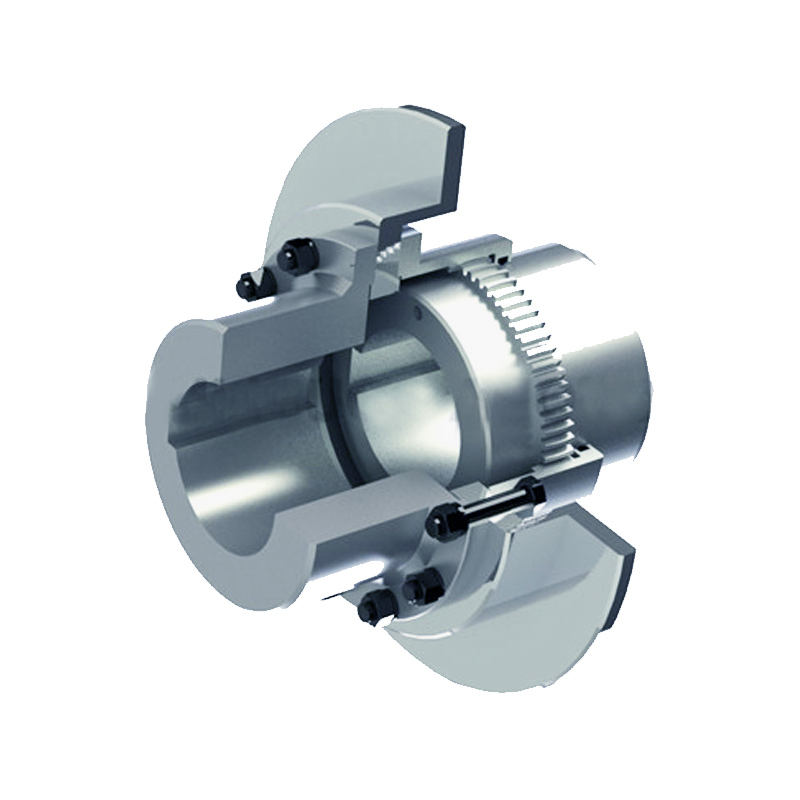

What Are Gear Couplings?

Gear couplings are mechanical devices designed to transmit torque between two shafts that are not collinear. They consist of two hubs with external teeth and a sleeve with internal teeth, allowing for slight misalignments while maintaining efficient power transmission. These couplings are widely used in heavy-duty industrial applications due to their high torque capacity, durability, and ability to accommodate angular, parallel, and axial misalignments. Gear couplings are essential in industries such as manufacturing, mining, and energy, where reliable machinery performance is critical.

Key Features of Gear Couplings

- High Torque Transmission: Capable of handling significant torque loads without slippage.

- Misalignment Compensation: Accommodates angular, parallel, and axial misalignments up to specified limits.

- Durability: Made from high-strength materials like alloy steel for long service life.

- Lubrication Options: Available in lubricated and non-lubricated (maintenance-free) designs.

- Easy Installation: Designed for straightforward assembly and disassembly, reducing downtime.

- Customizability: Can be tailored to specific application requirements, including size and material.

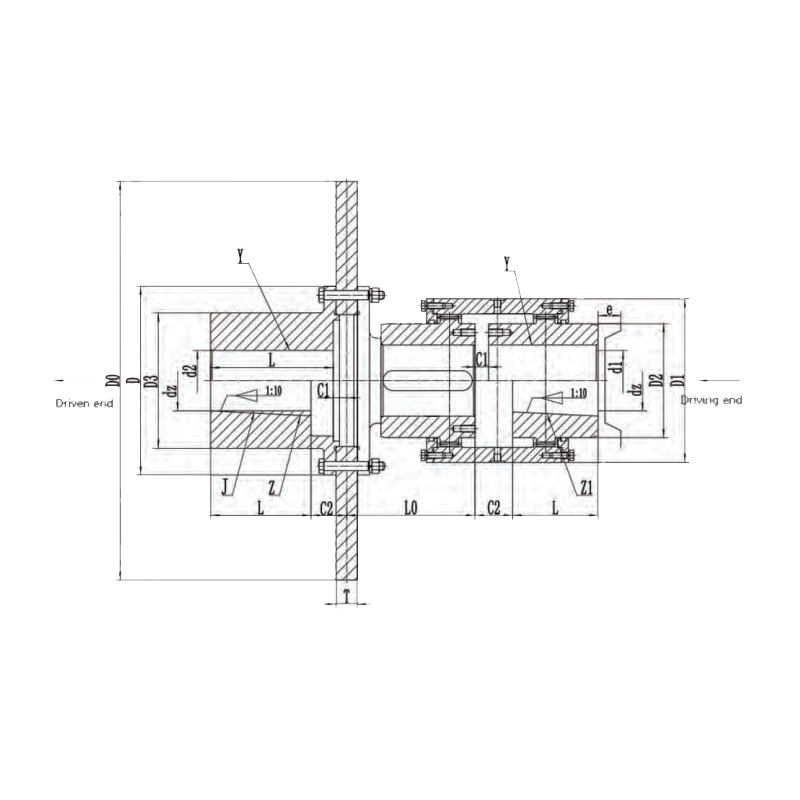

Product Parameters

Our gear couplings are engineered to meet rigorous industrial standards. Below are the detailed specifications presented in a table for clarity.

| Parameter |

Description |

Range/Options |

| Bore Diameter |

The inner diameter of the hub that fits onto the shaft. |

10 mm to 300 mm |

| Torque Capacity |

Maximum torque the coupling can transmit without failure. |

Up to 500,000 Nm |

| Speed Rating |

Maximum operational rotational speed. |

Up to 10,000 RPM |

| Misalignment Tolerance |

Allowable angular, parallel, and axial misalignment. |

Angular: ±1.5°, Parallel: ±0.5 mm, Axial: ±2 mm |

| Material |

Primary construction material for hubs and sleeves. |

Alloy Steel, Stainless Steel, Cast Iron |

| Weight |

Approximate weight of the coupling assembly. |

0.5 kg to 200 kg |

| Lubrication Type |

Method of lubrication for reduced wear. |

Grease-lubricated, Oil-lubricated, Maintenance-free |

| Temperature Range |

Operational temperature limits. |

-40°C to 150°C |

| Standards Compliance |

Industry standards met by the product. |

ISO 9001, AGMA, ANSI |

Applications of Gear Couplings

Gear couplings are versatile and used in various sectors. Common applications include:

- Industrial Machinery: Conveyors, pumps, compressors, and extruders.

- Power Generation: Turbines, generators, and wind turbines.

- Mining Equipment: Crushers, mills, and hoists.

- Marine Industry: Propulsion systems and auxiliary drives.

- Automotive Manufacturing: Assembly lines and testing equipment.

Advantages of Using Our Gear Couplings

- Enhanced Efficiency: Minimal power loss during transmission.

- Reduced Maintenance: Options for maintenance-free designs lower operational costs.

- Long Lifespan: Robust construction resists wear and tear.

- Safety: Designed to prevent failure under high loads, ensuring operator safety.

- Versatility: Suitable for a wide range of environments and temperatures.

Frequently Asked Questions (FAQ)

What is the primary function of a gear coupling?

Gear couplings are used to connect two shafts for torque transmission while accommodating misalignments and reducing shock loads.

How do I select the right gear coupling for my application?

Consider factors such as torque requirements, shaft size, misalignment type and degree, operational speed, and environmental conditions. Refer to our product table for specifications.

Can gear couplings be used in high-speed applications?

Yes, our gear couplings are rated for speeds up to 10,000 RPM, but always check the specific speed rating for your model to ensure compatibility.

What maintenance is required for gear couplings?

Lubricated types require periodic greasing or oiling, while maintenance-free versions use self-lubricating materials. Inspect regularly for wear and tear.

Are gear couplings suitable for corrosive environments?

Yes, we offer couplings made from stainless steel or with protective coatings to resist corrosion in harsh conditions.

What is the difference between gear couplings and other types like flexible couplings?

Gear couplings handle higher torque and misalignment compared to many flexible couplings, which are often used for lighter loads and simpler applications.

How do I install a gear coupling properly?

Ensure shafts are clean and aligned within tolerance. Slide the hubs onto the shafts, secure with keys or set screws, and attach the sleeve. Follow manufacturer guidelines for torque settings.

What are the signs of gear coupling failure?

Common indicators include unusual noise, vibration, overheating, lubricant leakage, or visible wear on teeth. Regular inspections can prevent sudden failures.

Can I customize a gear coupling for specific needs?

Absolutely. We provide custom options for bore size, material, and lubrication type to meet unique application requirements.

Do gear couplings require balancing?

For high-speed applications, dynamic balancing is recommended to minimize vibration and ensure smooth operation, especially in precision machinery.