What Are Type B Steel Hubs?

Type B Steel Hubs represent a specialized category of wheel hubs designed for heavy-duty applications, offering superior strength, durability, and reliability. They are engineered to meet rigorous industrial standards, making them ideal for use in commercial vehicles, agricultural machinery, and construction equipment. The hubs are constructed from high-grade steel, ensuring resistance to wear, corrosion, and extreme environmental conditions. Their precision manufacturing ensures seamless integration with various axle types, enhancing overall vehicle performance and safety. These hubs are a critical component in maintaining wheel assembly integrity, reducing downtime, and optimizing operational efficiency.

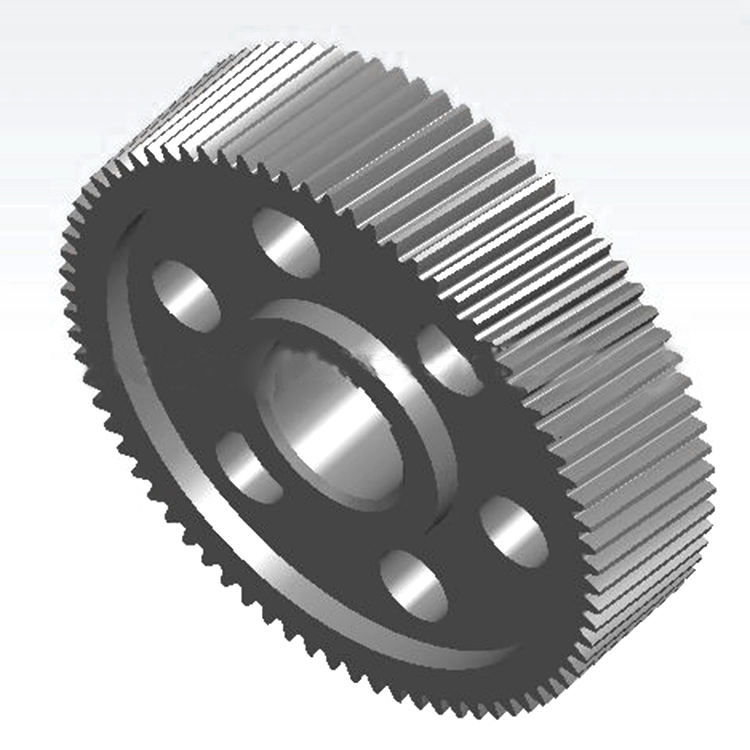

Key Features of Type B Steel Hubs

- Manufactured from high-tensile strength steel for enhanced durability.

- Precision-machined to ensure exact fit and smooth operation.

- Resistant to corrosion and abrasion, extending product lifespan.

- Designed with standardized bolt patterns for easy installation.

- Compatible with a wide range of vehicle models and axle configurations.

- Rigorous quality testing under load conditions to ensure reliability.

- Optimized weight distribution to reduce stress on adjacent components.

- Available in multiple sizes to cater to diverse industrial needs.

Technical Specifications of Type B Steel Hubs

| Parameter |

Specification |

Unit |

| Material Grade |

ASTM A36 Steel |

- |

| Weight Capacity |

Up to 5,000 kg per hub |

kg |

| Bolt Circle Diameter |

10 x 225 mm |

mm |

| Hub Bore Diameter |

160 mm |

mm |

| Surface Treatment |

Hot-dip galvanized |

- |

| Operating Temperature Range |

-40°C to 150°C |

°C |

| Compatibility |

ISO 4106 Standards |

- |

| Warranty Period |

2 years or 100,000 km |

- |

Applications of Type B Steel Hubs

Type B Steel Hubs are versatile components used across multiple industries due to their robust construction. In the transportation sector, they are essential for trucks, trailers, and buses, ensuring safe and efficient wheel rotation. Agricultural equipment, such as tractors and harvesters, benefits from their ability to withstand harsh field conditions. Construction machinery, including excavators and loaders, relies on these hubs for heavy-load support and longevity. Additionally, they are employed in industrial manufacturing for material handling vehicles, providing consistent performance under repetitive stress. Their adaptability makes them a preferred choice for OEMs and aftermarket replacements, enhancing vehicle uptime and reducing maintenance costs.

FAQ About Type B Steel Hubs

What materials are used in Type B Steel Hubs?

Type B Steel Hubs are crafted from high-quality ASTM A36 steel, which offers excellent tensile strength and impact resistance. The material undergoes hot-dip galvanization for corrosion protection, ensuring longevity even in moist or saline environments.

How do I determine the correct hub size for my vehicle?

To select the appropriate hub size, refer to your vehicle's manual for axle specifications, including bolt pattern dimensions and bore diameter. Alternatively, measure the existing hub's bolt circle (e.g., 10x225mm) and hub bore (e.g., 160mm) for accuracy. Consulting with a professional mechanic is recommended for precise fitment.

Are Type B Steel Hubs compatible with all axle types?

These hubs are designed to be compatible with standard axles adhering to ISO 4106 specifications. However, compatibility may vary based on vehicle make and model. Always verify axle type (e.g., full-floating or semi-floating) and mounting requirements before purchase to ensure proper integration.

What maintenance is required for Type B Steel Hubs?

Regular maintenance includes inspecting for wear, cracks, or corrosion every 10,000 km or as per manufacturer guidelines. Lubricate bearing surfaces during installation and periodically check torque settings on bolts. Avoid overloading beyond the specified capacity to prevent premature failure.

Can these hubs be used in extreme temperatures?

Yes, Type B Steel Hubs are engineered to operate efficiently in temperatures ranging from -40°C to 150°C. The steel composition and surface treatment provide thermal stability, making them suitable for diverse climates, from arctic cold to desert heat.

What is the average lifespan of a Type B Steel Hub?

Under normal operating conditions and proper maintenance, these hubs typically last between 150,000 to 200,000 km. Factors such as load intensity, environmental exposure, and driving habits can influence longevity, but the galvanized coating and robust design ensure extended durability.

Do you offer custom specifications for Type B Steel Hubs?

Custom options are available based on volume orders, including alterations in bolt patterns, bore sizes, or material thickness. Provide detailed requirements for a quote, noting that lead times may vary depending on complexity and production schedules.