What Are Miter Gears?

Miter gears are a type of bevel gear where the two gears have the same number of teeth and are mounted on shafts that are at a 90-degree angle to each other. They are designed to transmit motion and power between intersecting shafts, typically at a right angle, with a 1:1 ratio. These gears are widely used in various mechanical applications due to their efficiency, precision, and ability to change the direction of rotation smoothly. Common uses include automotive differentials, industrial machinery, robotics, and aerospace systems, where reliable and accurate motion transfer is crucial.

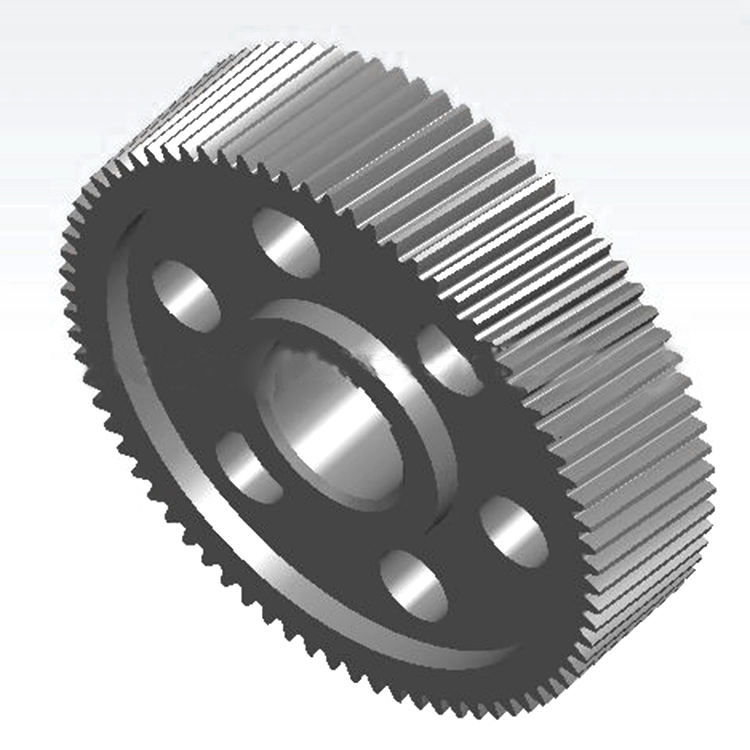

Key Features of Our Miter Gears

Our miter gears are manufactured to the highest standards, ensuring durability, performance, and longevity. They are made from premium materials such as hardened steel, stainless steel, and engineered plastics, catering to different environmental conditions and load requirements. The gears undergo rigorous quality control, including precision grinding and heat treatment, to minimize noise, reduce wear, and maximize efficiency. With options for custom specifications, our products are tailored to meet the specific needs of your application, providing seamless integration and optimal performance.

Detailed Product Parameters

Below is a comprehensive list of parameters for our miter gears, presented in both list and table formats for clarity and ease of reference. These parameters are essential for selecting the right gear for your needs, covering dimensions, materials, and performance characteristics.

Parameter List

- Gear Type: Miter Gear (Bevel Gear with 1:1 Ratio)

- Shaft Angle: 90 Degrees

- Number of Teeth: Range from 10 to 100 teeth, customizable

- Module (Pitch): Available from 0.5 to 10 module

- Pressure Angle: Standard 20 degrees, with options for 14.5 or 25 degrees

- Material: Hardened Steel, Stainless Steel, Brass, Nylon, or Other Engineering Plastics

- Surface Treatment: Options include black oxide, zinc plating, nitriding, or custom coatings

- Hardness: 45-65 HRC for steel gears, varies by material

- Precision Grade: AGMA Class 5 to 12, DIN standards available

- Max Torque Capacity: Up to 500 Nm, depending on size and material

- Operating Temperature Range: -40°C to 150°C, varies by material

- Lubrication: Grease or oil lubrication recommended; some materials are self-lubricating

- Noise Level: Low noise design, typically below 70 dB in standard applications

- Application: Suitable for automotive, industrial machinery, robotics, and more

Parameter Table

| Parameter |

Specification Range |

Notes |

| Module (Pitch) |

0.5 - 10 |

Determines tooth size; higher module for heavier loads |

| Number of Teeth |

10 - 100 |

Customizable to achieve specific ratios or sizes |

| Material |

Steel, Stainless Steel, Brass, Nylon |

Choice based on corrosion resistance, weight, and application |

| Hardness (HRC) |

45 - 65 |

For steel gears; other materials have varying hardness scales |

| Pressure Angle |

20° (standard), 14.5°, 25° |

Affects gear strength and smoothness of operation |

| Max Torque (Nm) |

Up to 500 |

Dependent on gear size and material; consult for specific values |

| Precision Grade |

AGMA 5-12, DIN 5-10 |

Higher grades for precision applications like aerospace |

| Weight |

Varies by size and material |

Lightweight options available in plastics |

FAQs About Miter Gears

Here are some frequently asked questions about miter gears, answered in detail to help you understand their functionality, selection, and maintenance.

What is the primary advantage of using miter gears over other types of gears?

Miter gears offer the advantage of transmitting motion at a 90-degree angle with a 1:1 ratio, ensuring efficient and precise direction change without speed variation. This makes them ideal for applications where space is constrained and exact motion transfer is required, such as in right-angle drives or differential systems. Additionally, their design minimizes backlash and wear when properly manufactured, leading to longer service life and reduced maintenance compared to some alternative mechanisms.

How do I select the right material for a miter gear based on my application?

Selecting the right material depends on factors like load capacity, environmental conditions, and cost. For high-load applications, hardened steel or stainless steel is recommended due to their strength and durability. In corrosive environments, stainless steel or coated options provide resistance. For lightweight or low-noise needs, engineering plastics like nylon are suitable, offering self-lubrication and reduced weight. Always consider operating temperature, as materials like plastic may have limitations in high-heat scenarios.

Can miter gears be used in high-speed applications?

Yes, miter gears can be used in high-speed applications, but it requires careful selection of precision grade, material, and lubrication. High-precision gears with AGMA Class 10 or better are designed to minimize vibration and noise at high speeds. Hardened steel gears with proper heat treatment and balanced design are preferred. Lubrication is critical to prevent overheating and wear; oil mist or forced lubrication systems may be necessary for speeds exceeding 1000 RPM. Always consult technical specifications to ensure compatibility.

What maintenance is required for miter gears to ensure longevity?

Regular maintenance includes periodic lubrication based on the operating environment and load. Inspect gears for wear, pitting, or misalignment every few months, especially in high-duty cycles. Clean gears to remove debris that could cause abrasion. For steel gears, check for corrosion and apply protective coatings if needed. Proper installation with accurate shaft alignment is crucial to prevent premature failure. Following manufacturer guidelines for lubrication intervals and using recommended lubricants will significantly extend gear life.

Are custom miter gears available for specific requirements?

Yes, we offer custom miter gears tailored to unique specifications, such as non-standard number of teeth, special materials, or specific tolerance levels. Customization can include modifications to pressure angle, module, or surface treatments to meet exact application needs. Provide details like shaft size, operating conditions, and performance requirements for a quote. Lead times may vary based on complexity, but we ensure high quality and compliance with international standards like AGMA or ISO.

How does the pressure angle affect the performance of a miter gear?

The pressure angle influences the gear's strength, noise level, and smoothness of operation. A standard 20-degree pressure angle offers a good balance between strength and quiet operation, suitable for most applications. A 14.5-degree angle provides smoother engagement and lower noise but may have reduced load capacity. A 25-degree angle increases strength and tooth durability for heavy loads but can generate more noise. Choosing the right pressure angle depends on the specific requirements of torque, speed, and environmental factors in your application.

What are common failure modes for miter gears, and how can they be prevented?

Common failure modes include wear, pitting, tooth breakage, and corrosion. Wear and pitting often result from inadequate lubrication or overload; prevent this by using proper lubricants and operating within rated torque limits. Tooth breakage can occur due to shock loads or misalignment; ensure correct installation and consider gears with higher hardness or toughness. Corrosion is mitigated by selecting corrosion-resistant materials or coatings. Regular inspection and maintenance are key to early detection and prevention of these issues.