What Are Plastic Gears?

Plastic gears are mechanical components made from various polymer materials, designed to transmit motion and power between machine parts. They offer advantages such as lightweight construction, corrosion resistance, cost-effectiveness, and noise reduction compared to metal gears. Commonly used in industries like automotive, consumer electronics, medical devices, and industrial machinery, plastic gears are engineered for precision and durability. With advancements in material science, modern plastic gears can handle high loads, resist wear, and operate efficiently in diverse environments, making them a versatile solution for many applications.

Key Features of Our Plastic Gears

Our plastic gears are manufactured to the highest standards, ensuring reliability and performance. Below is a list of their key features:

- High Strength-to-Weight Ratio: Made from engineered polymers, our gears are lightweight yet strong, reducing overall system weight without compromising durability.

- Corrosion Resistance: Unlike metal gears, they do not rust or corrode, making them ideal for humid or chemical environments.

- Low Noise Operation: The inherent damping properties of plastic result in quieter performance, suitable for applications where noise reduction is critical.

- Self-Lubricating Options: Many of our gears are made from materials that require minimal or no lubrication, reducing maintenance needs.

- Cost-Effective Production: Efficient manufacturing processes, such as injection molding, allow for high-volume production at lower costs compared to metal gears.

- Customizability: Available in various sizes, tooth profiles, and materials to meet specific application requirements.

Detailed Product Parameters

Our plastic gears come in a range of specifications to suit different needs. The parameters include material type, dimensions, load capacity, and operational limits. Below is a table summarizing the key parameters for our standard product line.

| Parameter |

Description |

Value Range |

| Material |

Type of polymer used (e.g., Nylon, Acetal, PEEK) |

Nylon 6/6, Acetal (POM), Polycarbonate, PEEK, UHMW-PE |

| Module (Metric) |

Gear size parameter indicating tooth size |

0.5 to 4.0 mm |

| Number of Teeth |

Total teeth count on the gear |

10 to 200 teeth |

| Pitch Diameter |

Diameter of the pitch circle |

5 mm to 400 mm |

| Face Width |

Width of the gear tooth along the axis |

3 mm to 50 mm |

| Load Capacity (Static) |

Maximum load before deformation |

50 N to 2000 N |

| Operating Temperature |

Temperature range for safe operation |

-40°C to 120°C (varies by material; e.g., PEEK up to 250°C) |

| Hardness (Rockwell) |

Material hardness measure |

R50 to R120 (e.g., Nylon ~ R110, Acetal ~ R120) |

| Backlash |

Amount of play between meshing teeth |

0.05 mm to 0.3 mm (adjustable based on design) |

| ISO Quality Grade |

Precision grade according to ISO standards |

Grade 6 to Grade 10 |

Material Options for Plastic Gears

We offer a variety of materials to match different application needs. Each material has unique properties that enhance performance in specific conditions. Here is a list of common materials used:

- Nylon (Polyamide): Known for its high strength, toughness, and wear resistance. Ideal for general-purpose applications. Often used with additives like glass fiber for improved performance.

- Acetal (POM): Offers low friction, high stiffness, and excellent dimensional stability. Suitable for precision gears in automotive and consumer goods.

- Polycarbonate: Provides high impact resistance and transparency. Used in applications where visibility or durability is key, such as medical devices.

- PEEK (Polyether Ether Ketone): A high-performance thermoplastic with excellent thermal stability, chemical resistance, and mechanical properties. Perfect for harsh environments like aerospace or oil and gas industries.

- UHMW-PE (Ultra-High Molecular Weight Polyethylene): Features exceptional abrasion resistance and low friction. Commonly used in food processing and conveyor systems.

Applications of Plastic Gears

Plastic gears are utilized across numerous industries due to their versatility. Below are some common applications:

- Automotive: Used in window regulators, seat adjusters, and transmission systems for reduced weight and noise.

- Consumer Electronics: Found in printers, scanners, and household appliances where quiet operation is essential.

- Medical Devices: Employed in diagnostic equipment, pumps, and surgical tools for their corrosion resistance and sterilizability.

- Industrial Machinery: Integrated into conveyors, robots, and packaging machines for cost-effective and maintenance-free operation.

- Aerospace: Used in non-critical systems to minimize weight and enhance fuel efficiency.

FAQ: Common Questions About Plastic Gears

What materials are best for high-temperature applications?

PEEK (Polyether Ether Ketone) is ideal for high-temperature environments, as it can withstand continuous operation up to 250°C while maintaining mechanical properties. Other options include heat-stabilized nylons, which can handle temperatures up to 120°C.

How do plastic gears compare to metal gears in terms of strength?

Plastic gears generally have lower tensile strength than metal gears but offer a higher strength-to-weight ratio. With advanced materials like glass-filled nylons or PEEK, plastic gears can achieve strengths comparable to some metals for specific loads, while being lighter and corrosion-resistant.

Can plastic gears be used in wet or humid conditions?

Yes, many plastic gears, especially those made from materials like acetal or certain nylons, are resistant to moisture and chemicals. However, some materials may absorb water, which can affect dimensions; in such cases, humidity-resistant grades or coatings are recommended.

What is the typical lifespan of a plastic gear?

The lifespan depends on factors like load, speed, material, and operating environment. Under moderate conditions, plastic gears can last for millions of cycles. For example, acetal gears in low-stress applications may operate reliably for over 10 years, while high-load scenarios might reduce lifespan but can be mitigated with proper design.

Do plastic gears require lubrication?

Many plastic gears are self-lubricating due to the inherent properties of materials like acetal or UHMW-PE, reducing the need for external lubrication. However, in high-speed or high-load applications, a light lubricant may be applied to extend life and reduce wear.

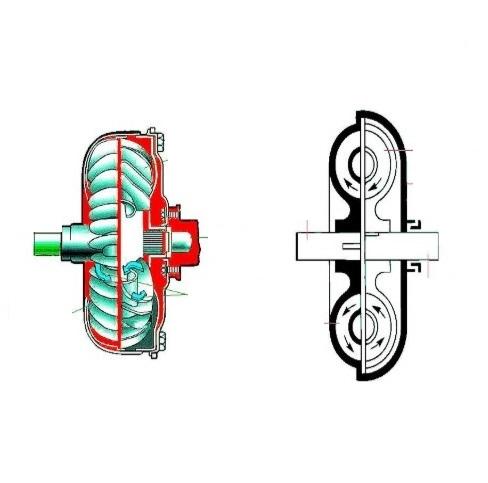

How are plastic gears manufactured?

Plastic gears are primarily produced through injection molding, which allows for high precision and mass production. Other methods include machining for prototypes or custom designs. The process involves melting polymer pellets and injecting them into molds to form the gear shape with accurate teeth profiles.

Can I get custom-designed plastic gears?

Yes, we offer custom design services where gears can be tailored to specific dimensions, tooth profiles, materials, and performance requirements. This includes prototyping and testing to ensure they meet your application needs.

What standards do your plastic gears comply with?

Our gears are manufactured in compliance with international standards such as ISO 9001 for quality management, and gear-specific standards like AGMA (American Gear Manufacturers Association) and DIN (Deutsches Institut für Normung) for dimensional accuracy and performance.

Are plastic gears environmentally friendly?

Many plastic gears are made from recyclable materials, and their production often has a lower carbon footprint compared to metal gears due to less energy-intensive processes. Additionally, some materials are bio-based or biodegradable, supporting sustainability initiatives.

How do I select the right plastic gear for my application?

Consider factors such as load capacity, operating speed, temperature range, environmental conditions (e.g., exposure to chemicals), and noise requirements. Consulting with our engineering team can help you choose the optimal material and design based on your specific needs.