What Are Split Taper Bushings?

Split taper bushings are mechanical components designed to securely connect rotating elements, such as gears, pulleys, or sprockets, to shafts. They feature a tapered design that allows for easy installation and removal, providing a tight grip without damaging the shaft. These bushings are split along their length, enabling them to compress and expand, which ensures a precise fit and excellent torque transmission. Commonly used in industrial machinery, automotive systems, and agricultural equipment, split taper bushings offer reliability, durability, and versatility in various applications.

Key Features of Split Taper Bushings

- High-strength materials for enhanced durability and load capacity.

- Tapered design for easy mounting and dismounting without special tools.

- Split construction allowing for adjustment and secure locking on shafts.

- Corrosion-resistant coatings or materials for use in harsh environments.

- Compatibility with standard shaft sizes and metric measurements.

- Minimal maintenance requirements due to robust design.

- Ability to handle high torque and rotational speeds efficiently.

- Wide range of sizes and types to suit diverse industrial needs.

Product Specifications

Our split taper bushings are manufactured to meet international standards, ensuring quality and performance. Below is a detailed table of specifications for our standard product line.

| Model Number |

Bore Diameter (mm) |

Outside Diameter (mm) |

Length (mm) |

Material |

Max Torque (Nm) |

Weight (kg) |

| STB-1001 |

10 - 30 |

40 |

50 |

Cast Iron |

150 |

0.5 |

| STB-1002 |

20 - 40 |

60 |

70 |

Steel |

300 |

1.2 |

| STB-1003 |

30 - 50 |

80 |

90 |

Stainless Steel |

500 |

2.0 |

| STB-1004 |

40 - 60 |

100 |

110 |

Alloy Steel |

750 |

3.5 |

| STB-1005 |

50 - 70 |

120 |

130 |

Cast Iron with Coating |

1000 |

5.0 |

Applications of Split Taper Bushings

Split taper bushings are versatile and used across multiple industries due to their efficiency and reliability. Common applications include:

- Conveyor systems in manufacturing and logistics.

- Power transmission equipment such as motors and drives.

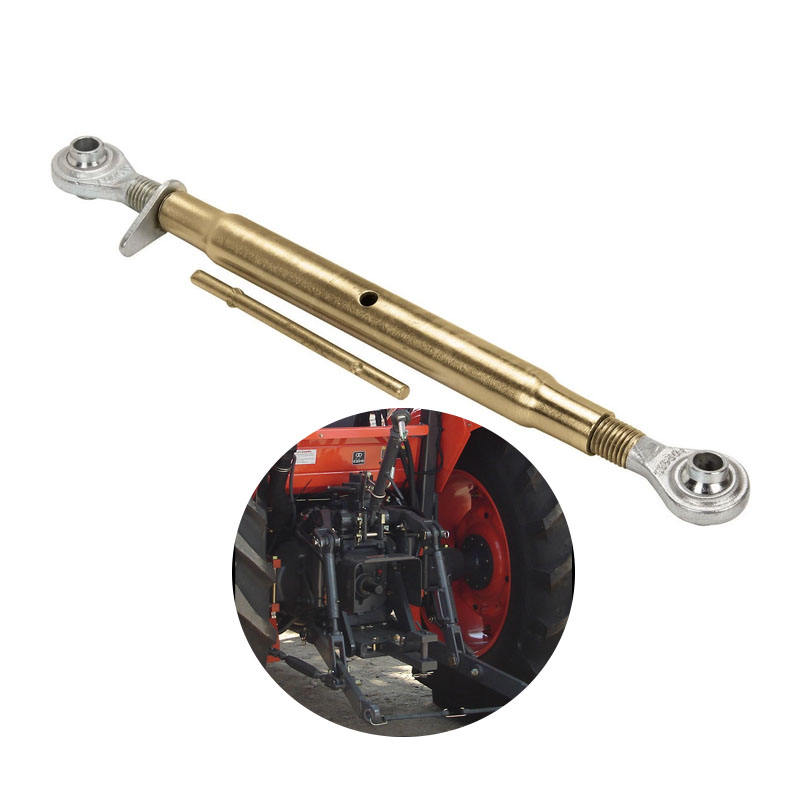

- Agricultural machinery like tractors and harvesters.

- Automotive assemblies for engines and transmissions.

- Mining equipment requiring heavy-duty performance.

- Marine applications where corrosion resistance is critical.

- Robotics and automation systems for precise motion control.

Advantages of Using Our Split Taper Bushings

- Easy installation and removal reduce downtime in maintenance.

- High grip strength prevents slipping and ensures efficient power transmission.

- Durable materials extend product life, even in demanding conditions.

- Cost-effective solution compared to custom-machined components.

- Wide availability of sizes and materials to match specific requirements.

- Compliance with ISO and ANSI standards for quality assurance.

- Environmentally friendly options with recyclable materials.

Frequently Asked Questions (FAQ)

What is a split taper bushing?

A split taper bushing is a mechanical device used to connect rotating parts to a shaft. It has a tapered, split design that allows it to be tightened onto the shaft, providing a secure fit without keyways or set screws, making it ideal for applications requiring frequent adjustments or replacements.

How do I install a split taper bushing?

To install, slide the bushing onto the shaft, align it with the hub of the component (e.g., a pulley), and tighten the locking screws evenly. This action causes the bushing to compress against the shaft, creating a firm grip. Always follow the manufacturer's torque specifications to avoid overtightening and ensure proper function.

What materials are split taper bushings made from?

They are typically manufactured from materials like cast iron, steel, stainless steel, or alloy steels, often with coatings such as zinc or phosphate for corrosion resistance. The choice of material depends on the application's requirements, including load capacity, environmental conditions, and compatibility with other components.

Can split taper bushings be reused?

Yes, split taper bushings can generally be reused if they are in good condition without significant wear or damage. However, it's essential to inspect them for cracks, deformation, or corrosion before reinstallation. Reusing damaged bushings can lead to failure and equipment downtime, so replacement is recommended if any defects are found.

What are the common sizes available?

Common sizes range from bore diameters of 10 mm to 70 mm, with outside diameters and lengths varying accordingly. Standard sizes are often based on metric or imperial systems, and custom sizes can be produced to meet specific needs. Refer to product catalogs or consult with suppliers for detailed sizing charts.

How do I maintain split taper bushings?

Maintenance involves regular inspections for wear, proper lubrication if applicable (though many are self-lubricating or require minimal lubrication), and ensuring that locking screws are tightened to the correct torque. Avoid exposure to extreme temperatures or corrosive substances without protective coatings to prolong lifespan.

Are split taper bushings compatible with all shaft types?

They are designed to be compatible with standard round shafts, but it's crucial to match the bushing size to the shaft diameter precisely. Some bushings may require keyways or additional fittings for specific applications. Always verify compatibility based on the manufacturer's specifications to ensure optimal performance.

What is the maximum torque a split taper bushing can handle?

The maximum torque varies by model and material, typically ranging from 150 Nm to over 1000 Nm for larger bushings. Refer to the product specifications table for exact values, and consider factors like operational speed and environmental conditions when selecting a bushing for high-torque applications.

Can I use split taper bushings in high-temperature environments?

Yes, but it depends on the material. Stainless steel or heat-treated alloy bushings are suitable for temperatures up to 400°C, while standard materials may have lower limits. Always check the material specifications and consider using bushings with high-temperature coatings or alternatives for extreme conditions.

Where can I purchase genuine split taper bushings?

Genuine bushings can be purchased from authorized distributors, industrial suppliers, or directly from manufacturers. Ensure to provide the model number or specifications to get the correct product, and verify certifications like ISO to guarantee quality and authenticity.