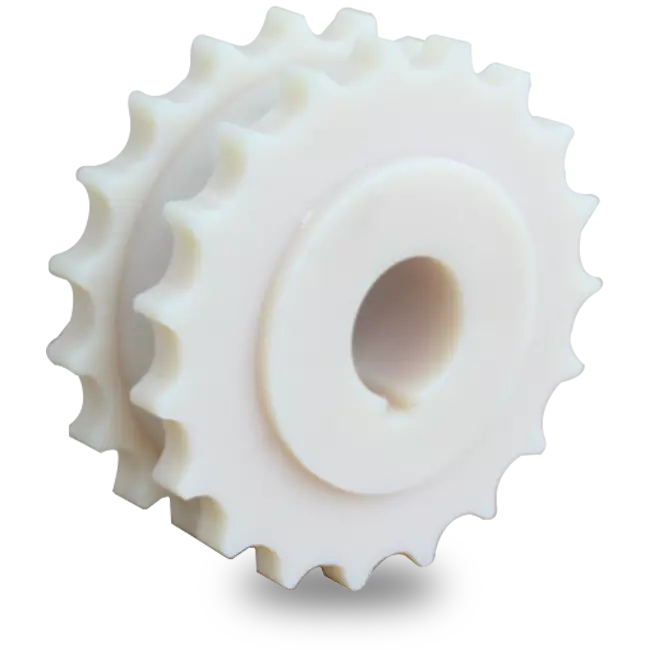

Plastic Sprockets: High-Performance Solutions for Modern Applications

Plastic sprockets are essential components in various industries, offering durability, lightweight properties, and corrosion resistance. At [Your Company Name], we specialize in manufacturing top-quality plastic sprockets designed to meet rigorous demands. Our products are engineered with precision using advanced materials like nylon, acetal, and polyethylene, ensuring optimal performance in diverse environments. Whether for conveyor systems, automotive applications, or industrial machinery, our plastic sprockets provide reliable power transmission with minimal maintenance. Below, we detail the key parameters and features that set our products apart, followed by a comprehensive FAQ section to address common queries.

Key Parameters of Our Plastic Sprockets

Our plastic sprockets are available in a range of sizes and configurations to suit specific needs. Here are the primary parameters:

- Material: Nylon, Acetal (POM), Polyethylene (PE), and other high-grade polymers.

- Tooth Count: Ranging from 6 to 60 teeth, customizable based on application requirements.

- Bore Size: Standard sizes from 1/4 inch to 2 inches, with options for keyways or set screws.

- Pitch: Common pitches include 1/4 inch, 3/8 inch, 1/2 inch, and metric equivalents like 8mm or 10mm.

- Operating Temperature: -40°F to 250°F (-40°C to 121°C), suitable for most industrial conditions.

- Load Capacity: Designed to handle static loads up to 500 lbs and dynamic loads based on material strength.

- Certifications: Compliant with ISO 9001 standards and RoHS directives for environmental safety.

Detailed Product Specifications Table

| Model Number |

Material |

Tooth Count |

Pitch (inches) |

Bore Size (inches) |

Max RPM |

Weight (oz) |

| PS-N25 |

Nylon |

25 |

1/2 |

3/4 |

1500 |

4.2 |

| PS-A18 |

Acetal |

18 |

3/8 |

1/2 |

2000 |

2.8 |

| PS-PE40 |

Polyethylene |

40 |

1/4 |

1 |

1200 |

6.5 |

| PS-N12 |

Nylon |

12 |

1/2 |

1/4 |

1800 |

1.5 |

Advantages of Using Plastic Sprockets

Plastic sprockets offer numerous benefits over metal alternatives. They are lightweight, reducing overall system weight and energy consumption. Their inherent corrosion resistance makes them ideal for humid or chemical-exposed environments. Additionally, plastic sprockets operate quietly, minimizing noise pollution in settings like food processing or packaging lines. The self-lubricating properties of materials like nylon reduce maintenance needs, extending equipment lifespan. Cost-effectiveness is another key advantage, as plastic sprockets are often more affordable to produce and replace, without compromising on performance.

FAQ: Common Questions About Plastic Sprockets

What are the main applications for plastic sprockets?

Plastic sprockets are widely used in conveyor systems, automotive timing mechanisms, agricultural equipment, and packaging machinery. They are also common in environments where metal corrosion is a concern, such as in food processing, pharmaceuticals, and marine applications.

How do I choose the right material for my plastic sprocket?

Select the material based on your application's requirements: nylon for high strength and wear resistance, acetal for low friction and dimensional stability, and polyethylene for chemical resistance and affordability. Consider factors like load, temperature, and exposure to chemicals or moisture.

Can plastic sprockets handle high-speed operations?

Yes, many plastic sprockets, especially those made from acetal or reinforced nylon, can operate at speeds up to 2000 RPM or higher. Always refer to the manufacturer's specifications for maximum RPM based on the sprocket size and material to ensure safe operation.

Are plastic sprockets compatible with all types of chains?

Plastic sprockets are designed to work with standard roller chains, such as ANSI or metric chains. It is crucial to match the sprocket's pitch and tooth profile with the chain type to prevent premature wear or failure. Consult our product guide for compatibility details.

How do I maintain plastic sprockets to extend their lifespan?

Maintenance is minimal due to self-lubricating materials, but regular inspections for wear, cracks, or deformation are recommended. Clean sprockets periodically to remove debris, and avoid over-tightening during installation. Replace sprockets if teeth show significant wear to prevent chain slippage.

What are the environmental benefits of using plastic sprockets?

Plastic sprockets are often made from recyclable materials and contribute to energy savings due to their lightweight nature, reducing the carbon footprint of machinery. They also eliminate the need for harmful lubricants in some cases, supporting greener operations.

Can I get custom-designed plastic sprockets for unique applications?

Yes, we offer custom manufacturing services for plastic sprockets, including specific tooth counts, bore sizes, and material blends. Provide your application details, and our engineering team will develop a solution tailored to your needs, ensuring optimal performance and compatibility.