FAQ: Frequently Asked Questions About Plastic Chains

What materials are commonly used in plastic chains?

Plastic chains are typically made from polymers like polypropylene (PP), polyethylene (PE), and acetal (POM). PP offers good chemical resistance and is cost-effective, PE provides flexibility and impact strength, and POM (acetal) delivers high tensile strength and low friction, making it ideal for precision applications. The choice depends on factors such as load capacity, environmental conditions, and specific industry requirements, ensuring optimal performance and durability.

How do I determine the right chain pitch for my application?

Chain pitch, the distance between chain pins, should be selected based on your conveyor system's design and load demands. Smaller pitches (e.g., 0.5 inch) are suitable for lightweight, high-speed applications, while larger pitches (e.g., 4 inches) handle heavier loads and reduce wear. Consult your system specifications or our technical team to match the pitch with sprocket size and operational speed, ensuring smooth operation and minimizing maintenance issues.

Are plastic chains suitable for outdoor use?

Yes, many plastic chains are UV-stabilized to withstand outdoor conditions without degrading. Materials like polyethylene and specially treated polypropylene resist sunlight, moisture, and temperature fluctuations. However, it's essential to verify the product's UV rating and temperature range specifications to ensure longevity. For extreme environments, consider chains with added stabilizers or consult our experts for customized solutions.

What maintenance is required for plastic chains?

Plastic chains require minimal maintenance compared to metal chains. Regular inspections for wear, cracks, or debris buildup are recommended. Clean them with mild detergents and water to remove contaminants, avoiding harsh chemicals that might damage the material. Lubrication is generally not needed due to their self-lubricating properties, but in high-friction applications, use compatible lubricants. Replace chains if signs of excessive wear appear to prevent system failures.

Can plastic chains be used in food-grade applications?

Absolutely. Plastic chains made from FDA-approved materials like certain grades of polypropylene or polyethylene are safe for food contact. They resist bacterial growth, are easy to sanitize, and comply with USDA and other food safety standards. Ensure the chain has smooth surfaces and no crevices to prevent contamination, and choose options certified for food processing to meet regulatory requirements.

How do plastic chains compare to metal chains in terms of cost and performance?

Plastic chains are generally more cost-effective than metal chains due to lower material and production costs. They offer superior corrosion resistance, lighter weight, and quieter operation, reducing energy consumption and noise pollution. However, metal chains may excel in extremely high-temperature or ultra-heavy-load scenarios. Plastic chains provide excellent performance for most industrial applications, with longer lifespan in corrosive environments and lower overall maintenance expenses.

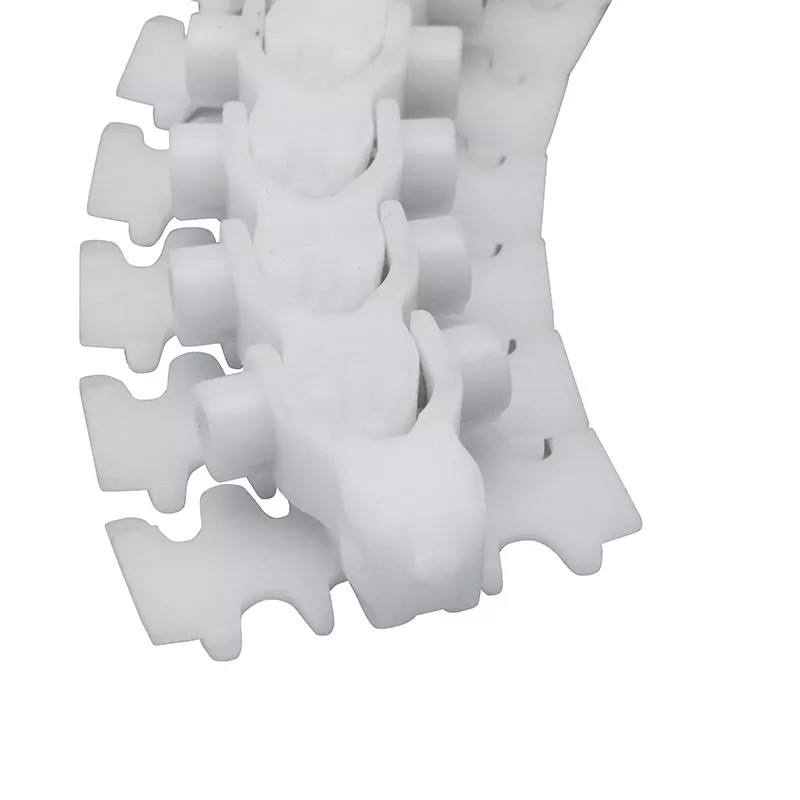

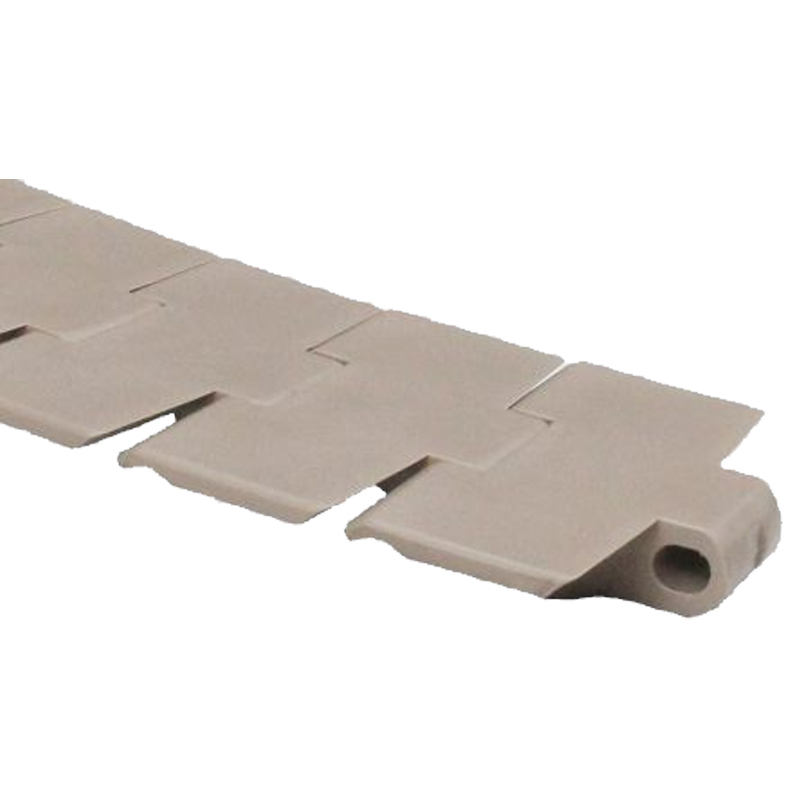

What attachments are available for plastic chains?

A variety of attachments can be integrated with plastic chains to enhance functionality, including flat-top plates for stable conveying, rollers for reduced friction, side-flexing designs for curved paths, and magnetic options for ferrous material handling. Attachments are customizable based on your application, such as adding flights for incline conveying or special hooks for lifting. Discuss your needs with our team to select the best attachment type for efficiency and safety.