What is a Shaft Mounted Gearbox?

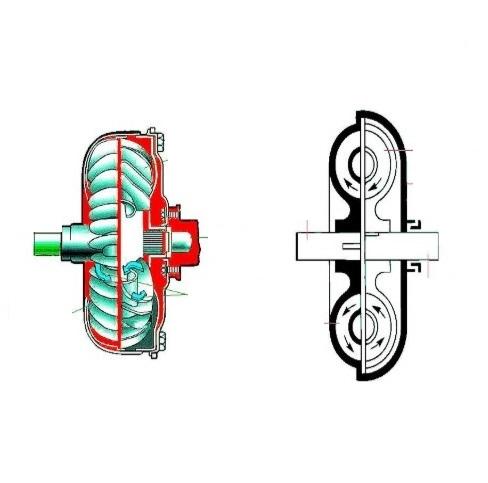

A shaft mounted gearbox, often referred to as a shaft mount reducer, is a type of gearbox that mounts directly onto the driven shaft of machinery, eliminating the need for foundations, couplings, or baseplates. This design offers a compact and efficient solution for transmitting power in various industrial applications, such as conveyors, mixers, and agricultural equipment. Its key advantage lies in its ease of installation, maintenance, and space-saving properties, making it a popular choice in many industries.

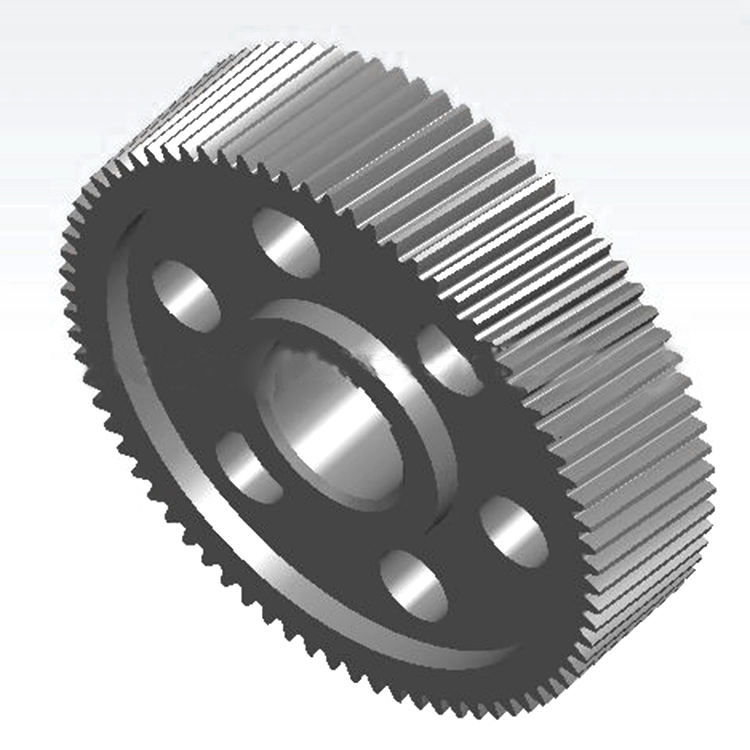

Key Features of Our Shaft Mounted Gearbox

- Robust cast iron housing for durability and reduced vibration

- High-quality hardened and ground gears for efficient power transmission

- Easy mounting and dismounting with standard tools

- Sealed against dust and moisture to enhance longevity

- Available in various sizes and gear ratios to suit diverse applications

- Low maintenance requirements with accessible lubrication points

Product Specifications

| Model |

Ratio Range |

Output Torque (Nm) |

Input Power (kW) |

Weight (kg) |

| SMG-100 |

5:1 to 30:1 |

Up to 500 |

0.5 - 5 |

15 |

| SMG-200 |

5:1 to 40:1 |

Up to 1200 |

5 - 15 |

35 |

| SMG-300 |

5:1 to 50:1 |

Up to 2500 |

15 - 30 |

70 |

| SMG-400 |

5:1 to 60:1 |

Up to 5000 |

30 - 55 |

120 |

Applications of Shaft Mounted Gearbox

Shaft mounted gearboxes are versatile and used across multiple industries. Common applications include conveyor systems in manufacturing and mining, where they provide reliable speed reduction. In agriculture, they power equipment like feeders and mixers. They are also found in construction machinery, food processing lines, and packaging systems, offering efficient torque transmission without complex setups.

FAQs About Shaft Mounted Gearbox

What is the primary advantage of using a shaft mounted gearbox?

The main advantage is its direct mounting onto the driven shaft, which simplifies installation, reduces space requirements, and eliminates the need for additional components like couplings or baseplates, leading to cost savings and easier maintenance.

How do I select the right size and ratio for my application?

To choose the appropriate size, consider factors such as the required output torque, input power, speed ratio, and the shaft diameter of your machinery. Refer to the product specifications table and consult with technical support if needed to ensure optimal performance.

What maintenance is required for a shaft mounted gearbox?

Regular maintenance includes checking and replenishing lubricant levels, inspecting seals for leaks, and ensuring proper mounting tightness. typically, lubrication should be done every 1,000 to 2,000 hours of operation, depending on the environment and usage.

Can a shaft mounted gearbox be used in harsh environments?

Yes, many models are designed with sealed housings and corrosion-resistant materials to withstand harsh conditions, such as dust, moisture, and extreme temperatures. Always verify the IP rating or environmental specifications for your specific model.

What is the typical lifespan of a shaft mounted gearbox?

With proper installation and maintenance, a shaft mounted gearbox can last for many years, often exceeding 10,000 hours of operation. Lifespan depends on factors like load conditions, maintenance frequency, and operational environment.

Are there customization options available?

Yes, customization options include special shaft sizes, gear ratios, mounting configurations, and material selections to meet specific application requirements. Contact our sales team for tailored solutions.