What Are QD Type Weld-On Hubs?

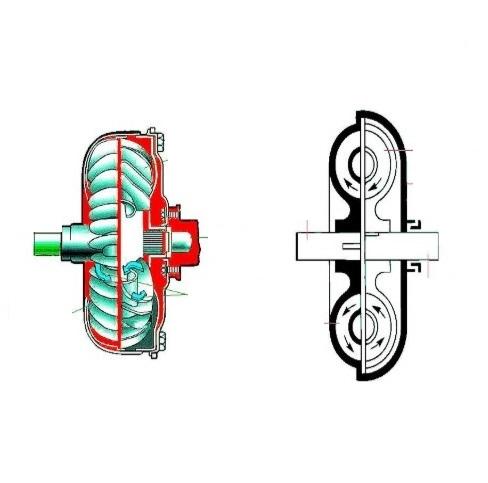

QD Type Weld-On Hubs are precision-engineered components designed for secure and efficient power transmission in heavy-duty industrial applications. These hubs feature a quick-disconnect (QD) mechanism that allows for easy installation and removal, making them ideal for machinery where frequent maintenance or part replacement is necessary. Constructed from high-strength materials, they ensure durability and reliability under extreme conditions. The weld-on design provides a permanent, robust connection to shafts or other components, minimizing slippage and maximizing torque transfer. Commonly used in agricultural, manufacturing, and automotive industries, QD Type Weld-On Hubs offer versatility and performance, backed by rigorous testing to meet industry standards.

Applications of QD Type Weld-On Hubs

QD Type Weld-On Hubs are widely used across multiple industries due to their robustness and adaptability. In agriculture, they are employed in equipment like tractors and harvesters for power transmission systems. The manufacturing sector utilizes these hubs in conveyor systems, robotics, and assembly lines, where precise motion control is critical. Automotive applications include use in drivetrains and suspension systems, ensuring reliable performance under stress. Additionally, they are found in construction machinery, such as cranes and excavators, where heavy loads and harsh conditions demand durable components. Their quick-disconnect feature makes them suitable for applications requiring frequent maintenance or part changes, reducing downtime and improving efficiency.

Frequently Asked Questions (FAQ)

What does "QD" stand for in QD Type Weld-On Hubs?

QD stands for "Quick-Disconnect," referring to the mechanism that allows for fast and easy attachment and detachment of the hub from a shaft or component, facilitating maintenance and replacements without extensive downtime.

Are QD Type Weld-On Hubs reusable after welding?

No, the weld-on design is intended for permanent installation. Once welded, the hub cannot be easily removed without damaging the components. For applications requiring frequent changes, consider using bolt-on or clamp-style hubs instead.

What materials are commonly used for these hubs?

They are typically made from high-strength materials such as carbon steel, stainless steel, or alloy steel, chosen for their durability, resistance to wear, and ability to withstand high loads and temperatures.

How do I choose the right size hub for my application?

Select a hub based on the shaft diameter, torque requirements, and environmental conditions. Refer to the product specifications table for diameter ranges and load capacities, and consult engineering guidelines or a professional if unsure.

Can these hubs be used in corrosive environments?

Yes, options with corrosion-resistant coatings like zinc plating or powder coating are available. For highly corrosive settings, stainless steel hubs are recommended to ensure longevity and performance.

What maintenance is required for QD Type Weld-On Hubs?

Regular inspections for cracks, wear, or corrosion are essential. In high-vibration applications, check for loosening over time. No lubrication is typically needed, but keep the area clean to prevent debris buildup.

Are there industry standards that these hubs comply with?

Yes, they often meet standards such as ISO 9001 for quality management and ANSI B18.3 for dimensional consistency, ensuring reliability and compatibility with other components.

What is the typical lifespan of a QD Type Weld-On Hub?

With proper installation and maintenance, these hubs can last for many years, even in demanding conditions. Lifespan depends on factors like load, operating environment, and material quality, but they are designed for long-term use.