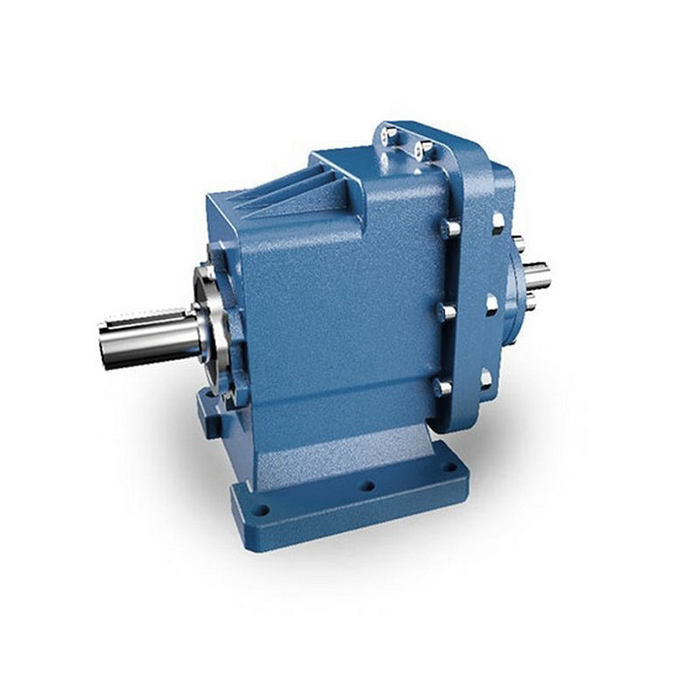

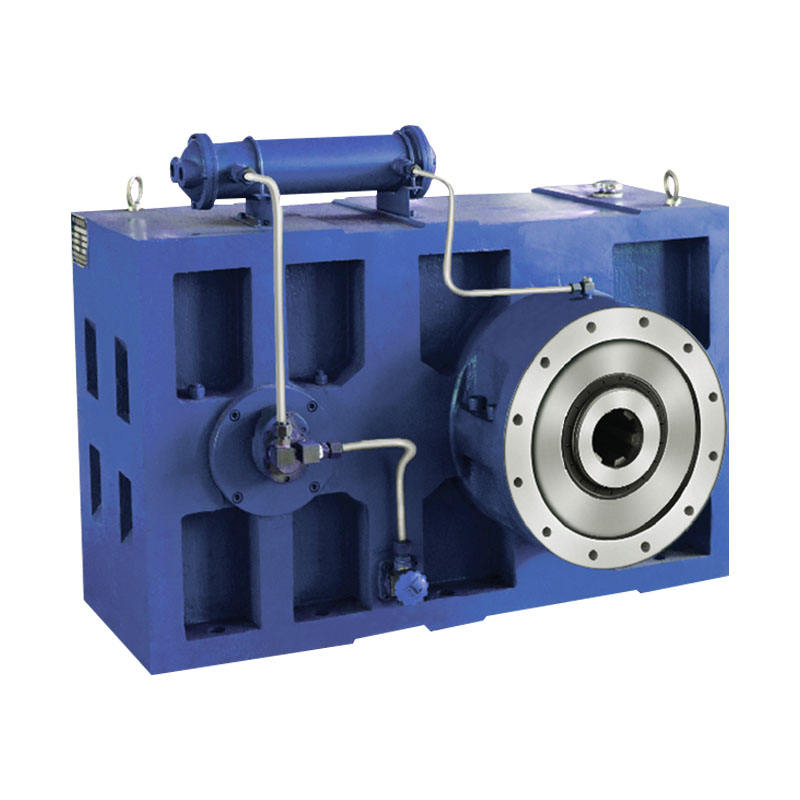

Introduction to Helical Gearbox

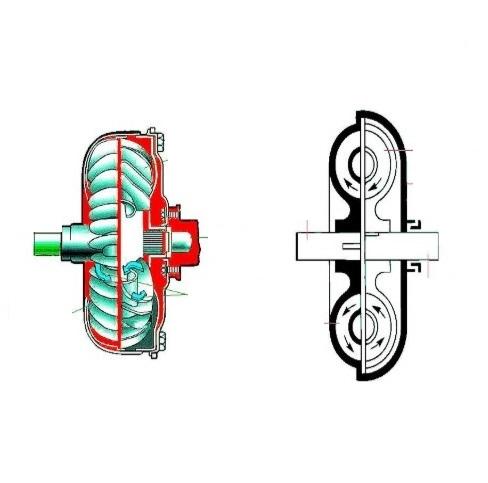

Helical gearboxes are a cornerstone of industrial machinery, renowned for their efficiency, durability, and smooth operation. Unlike spur gears, helical gears feature teeth that are cut at an angle to the gear axis, allowing for gradual engagement and reduced noise and vibration. This makes them ideal for high-speed and high-torque applications across various industries, including manufacturing, automotive, and material handling. With over two decades of expertise in power transmission systems, we offer premium helical gearboxes designed to meet the rigorous demands of modern engineering. Our products are engineered with precision, using high-quality materials to ensure longevity and optimal performance. Whether you're upgrading existing equipment or integrating new systems, our helical gearboxes provide reliable power transmission solutions that enhance operational efficiency and reduce maintenance costs.

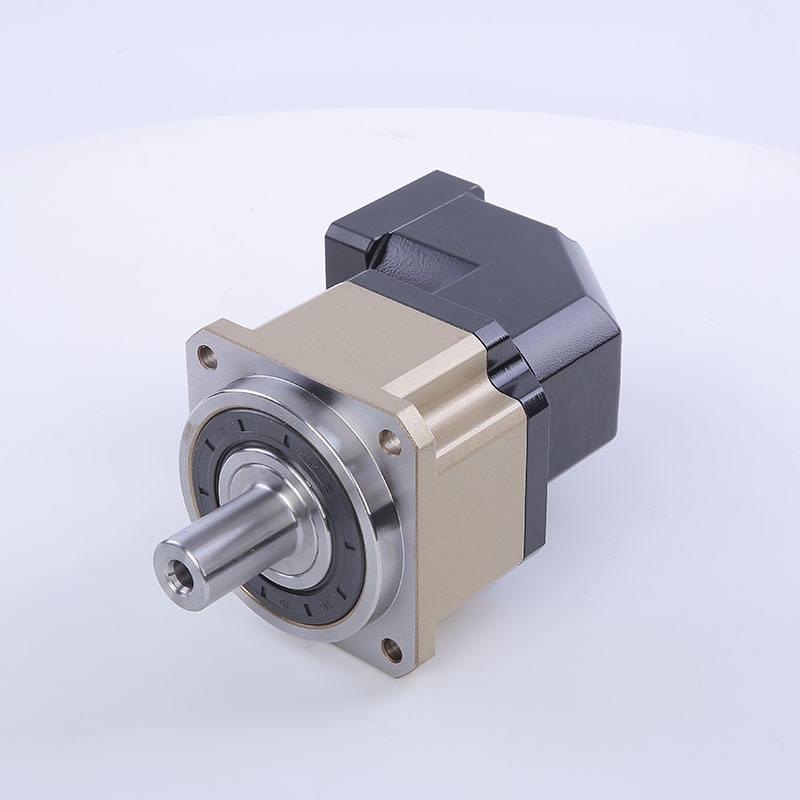

Key Features of Helical Gearbox

- Angled teeth design for smooth and quiet operation, minimizing noise pollution in industrial environments.

- High load-bearing capacity due to increased surface contact between gears, ensuring durability under heavy loads.

- Superior efficiency with power transmission rates up to 98%, reducing energy consumption and operational costs.

- Compact and robust construction, allowing for easy integration into various machinery without requiring excessive space.

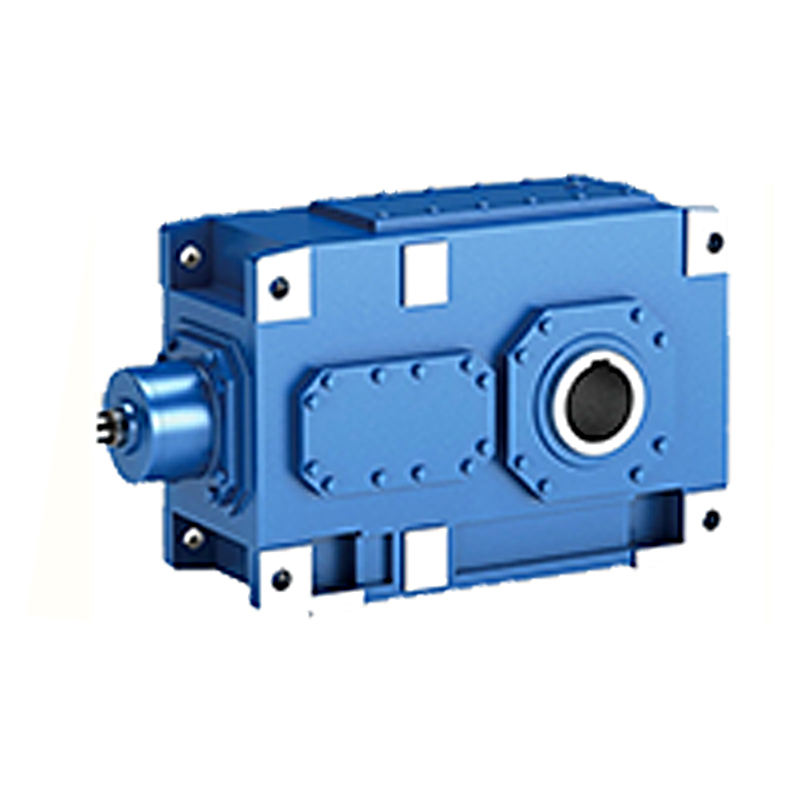

- Available in multiple configurations, including single, double, and triple reduction stages, to suit diverse application needs.

- Manufactured from high-strength materials such as hardened steel or cast iron, providing resistance to wear and corrosion.

- Advanced lubrication systems maintain optimal performance and extend service life, even in harsh operating conditions.

Detailed Product Parameters

Our helical gearboxes come in a range of sizes and specifications to cater to different industrial requirements. Below is a comprehensive table outlining the key parameters for our standard models. These parameters include gear ratio, input speed, output torque, efficiency, weight, and dimensions, ensuring you can select the perfect gearbox for your application. All measurements are based on international standards to guarantee compatibility and performance.

| Model |

Gear Ratio |

Input Speed (RPM) |

Output Torque (Nm) |

Efficiency (%) |

Weight (kg) |

Dimensions (LxWxH in mm) |

| HG-100 |

5:1 to 20:1 |

Up to 3000 |

100 - 500 |

95-98 |

15 |

200x150x100 |

| HG-200 |

10:1 to 30:1 |

Up to 2500 |

500 - 1500 |

96-98 |

30 |

300x200x150 |

| HG-300 |

15:1 to 40:1 |

Up to 2000 |

1500 - 3000 |

97-98 |

50 |

400x250x200 |

| HG-400 |

20:1 to 50:1 |

Up to 1500 |

3000 - 6000 |

97-98 |

80 |

500x300x250 |

Note: Custom configurations are available upon request to meet specific torque, speed, or environmental requirements. Contact our engineering team for tailored solutions.

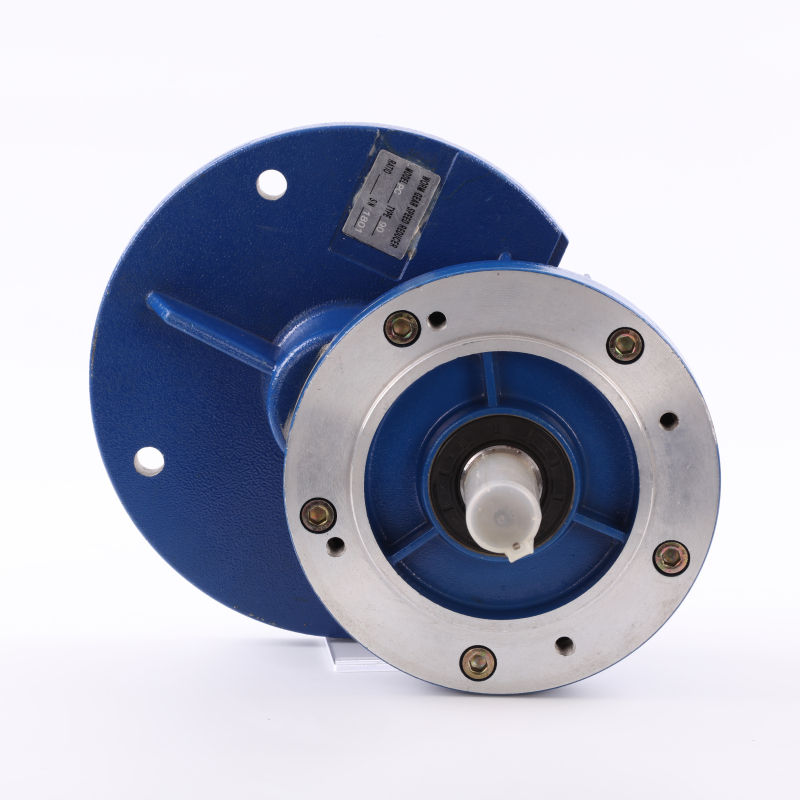

Applications of Helical Gearbox

- Conveyor systems in logistics and warehousing for smooth material handling.

- Automotive manufacturing lines for precision power transmission in assembly processes.

- Mining equipment, where high torque and reliability are essential for heavy-duty operations.

- Food processing machinery, benefiting from quiet operation and hygiene-compliant designs.

- Renewable energy systems, such as wind turbines, for efficient power conversion.

- Packaging industry machines, ensuring consistent speed and torque for automated processes.

Helical Gearbox FAQ

What is a helical gearbox and how does it differ from other gear types?

A helical gearbox utilizes gears with teeth cut at an angle to the axis, enabling gradual tooth engagement. This design reduces noise and vibration compared to spur gearboxes, which have straight teeth and can be louder. Helical gearboxes also offer higher load capacity and efficiency, making them suitable for applications requiring smooth and reliable power transmission.

What are the main advantages of using a helical gearbox?

The primary advantages include superior efficiency due to reduced friction, quieter operation from the angled teeth design, higher torque capacity because of increased surface contact, and longer lifespan with proper maintenance. These benefits lead to lower energy costs, improved workplace comfort, and reduced downtime in industrial settings.

How do I select the right helical gearbox for my application?

Consider factors such as required gear ratio, input and output speeds, torque demands, operating environment (e.g., temperature, humidity), and space constraints. Refer to the product parameter table above for standard models, and consult with our technical team for personalized recommendations based on your specific needs, including customizations for extreme conditions.

What maintenance is required for a helical gearbox?

Regular maintenance includes periodic lubrication checks and changes using recommended oils, inspection for wear or damage on gears and bearings, and ensuring proper alignment during installation. Maintenance intervals depend on usage intensity; for high-duty cycles, inspect every 3-6 months, while lighter applications may require annual checks. Always follow the manufacturer's guidelines to prevent failures.

Can helical gearboxes be used in high-temperature environments?

Yes, many of our helical gearboxes are designed with heat-resistant materials and special lubricants that withstand temperatures up to 80°C (176°F) continuously. For higher temperatures, we offer custom solutions with enhanced cooling systems or materials like stainless steel to ensure performance and durability without compromising efficiency.

Are helical gearboxes suitable for bidirectional operation?

Absolutely. Helical gearboxes are engineered for bidirectional rotation, making them versatile for applications where direction changes are frequent, such as in reversible conveyors or mixing equipment. The angled teeth design ensures smooth engagement in both directions, maintaining efficiency and reducing wear over time.

What is the typical lifespan of a helical gearbox?

With proper installation and maintenance, a high-quality helical gearbox can last 20,000 to 50,000 hours of operation, depending on load conditions and environmental factors. Factors like overload, poor lubrication, or misalignment can shorten lifespan, so adherence to operational guidelines is crucial for maximizing longevity.

Do you provide customization options for helical gearboxes?

Yes, we offer extensive customization, including specific gear ratios, mounting configurations, material choices (e.g., corrosion-resistant coatings for marine environments), and integration with other components. Our engineering team works closely with clients to develop tailored solutions that meet unique application requirements, ensuring optimal performance and compatibility.