What Are Conveyor Chains?

Conveyor chains are essential components in various industrial and manufacturing processes, designed to move materials efficiently along a production line. They consist of interconnected links that form a continuous loop, driven by sprockets, to transport goods smoothly and reliably. These chains are built to withstand heavy loads, high speeds, and harsh environments, making them ideal for applications in industries such as food processing, automotive, packaging, and mining. With advancements in materials and design, conveyor chains offer durability, low maintenance, and customization to meet specific operational needs, ensuring seamless material handling and increased productivity.

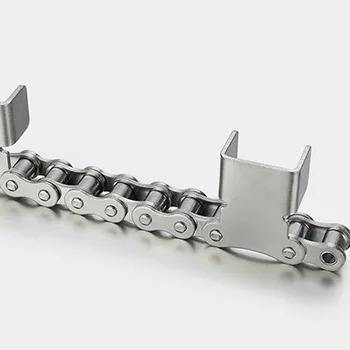

Key Features of Our Conveyor Chains

- High tensile strength for heavy-duty applications

- Corrosion-resistant coatings for extended lifespan

- Precision engineering for smooth operation and reduced noise

- Customizable lengths and widths to fit various conveyor systems

- Low friction design to minimize energy consumption

- Easy installation and maintenance with accessible components

- Compliance with international standards such as ISO and ANSI

- Temperature resistance for use in extreme environments

Detailed Product Parameters

| Parameter |

Description |

Value Range |

| Material |

Primary construction materials used |

Stainless Steel, Carbon Steel, Plastic, Nickel-Plated |

| Chain Pitch |

Distance between chain pins |

0.5 inch to 4 inches |

| Working Load |

Maximum load capacity during operation |

Up to 10,000 lbs |

| Operating Temperature |

Range of temperatures the chain can withstand |

-40°F to 500°F (-40°C to 260°C) |

| Speed Capacity |

Maximum operational speed |

Up to 200 feet per minute |

| Lubrication Requirement |

Type and frequency of lubrication needed |

Self-lubricating or manual every 500 hours |

| Chain Width |

Width of the chain assembly |

1 inch to 12 inches |

| Weight per Foot |

Approximate weight for logistics planning |

0.5 lbs to 15 lbs per foot |

Applications of Conveyor Chains

Conveyor chains are versatile and used across multiple sectors. In the food industry, they facilitate hygienic transport of products, often made from stainless steel to prevent contamination. Automotive assembly lines rely on them for moving parts efficiently, while mining operations use heavy-duty chains to handle abrasive materials. Packaging industries benefit from their precision in sorting and transporting items, and in agriculture, they assist in grain handling. Each application demands specific chain properties, such as resistance to moisture, chemicals, or wear, which our products are engineered to provide, ensuring optimal performance and longevity.

Comparison Table: Conveyor Chain Types

| Chain Type |

Best For |

Advantages |

Limitations |

| Roller Chains |

High-speed applications |

Low friction, durable, easy to maintain |

Not ideal for corrosive environments |

| Flat Top Chains |

Packaging and bottling |

Smooth surface, hygienic, quiet operation |

Lower load capacity compared to others |

| Magnetic Chains |

Electronics and metal handling |

Secures ferrous materials, precise positioning |

Higher cost, limited to specific uses |

| Oven Chains |

High-temperature processes |

Heat-resistant, minimal expansion |

Requires regular lubrication in extreme heat |

Frequently Asked Questions (FAQ)

What materials are commonly used in conveyor chains?

Conveyor chains are typically made from materials like stainless steel for corrosion resistance in food and chemical industries, carbon steel for high strength in heavy-duty applications, plastic for lightweight and quiet operation, and nickel-plated options for enhanced durability and aesthetic appeal in visible systems.

How do I choose the right conveyor chain for my application?

Selecting the appropriate conveyor chain depends on factors such as load capacity, operating environment (e.g., temperature, moisture), speed requirements, and material compatibility. Consider consulting with our experts or referring to the product parameters table to match your specific needs, ensuring optimal performance and longevity.

What maintenance is required for conveyor chains?

Regular maintenance includes lubrication every 500 hours for non-self-lubricating chains, inspection for wear or damage, cleaning to remove debris, and tension adjustments to prevent slippage. Proper maintenance extends the chain's life and prevents downtime, with detailed guidelines provided in our product manuals.

Can conveyor chains be customized?

Yes, we offer customization options for length, width, pitch, material, and special coatings to suit unique applications. Custom chains can be designed for specific industries, such as high-temperature resistance for ovens or hygienic designs for food processing, ensuring a perfect fit for your conveyor system.

What is the average lifespan of a conveyor chain?

The lifespan varies based on usage, maintenance, and environment, but typically ranges from 5 to 15 years. Factors like load intensity, operating speed, and exposure to corrosive elements can affect durability. Regular maintenance and choosing the right chain type can maximize lifespan, as outlined in our product specifications.

Are there safety standards for conveyor chains?

Yes, conveyor chains must comply with international standards such as ISO 606 for dimensions and ANSI B29.1 for safety and performance. Our products are tested and certified to meet these standards, ensuring safe operation and reliability in industrial settings, with documentation available upon request.

How do I install a conveyor chain properly?

Installation involves aligning the chain with sprockets, ensuring proper tension, and securing connections. Follow the step-by-step guide in our manual, which includes tips for avoiding common issues like misalignment or overtightening. For complex systems, professional installation services are recommended to ensure efficiency and safety.

What are the signs that a conveyor chain needs replacement?

Indicators include excessive noise, visible wear on links or pins, reduced efficiency, frequent slippage, or elongation beyond acceptable limits. Regular inspections help detect these signs early, preventing breakdowns and maintaining productivity, as detailed in our maintenance recommendations.