What Are Bushed and Taper Lock Sprockets?

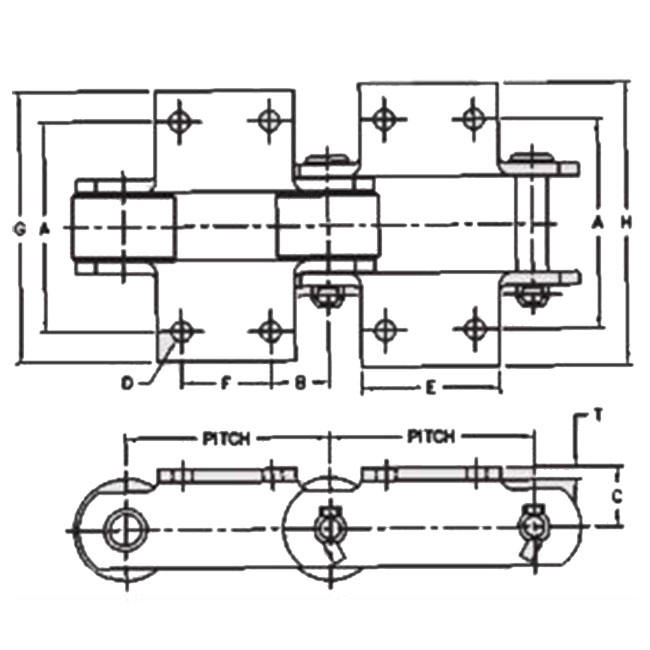

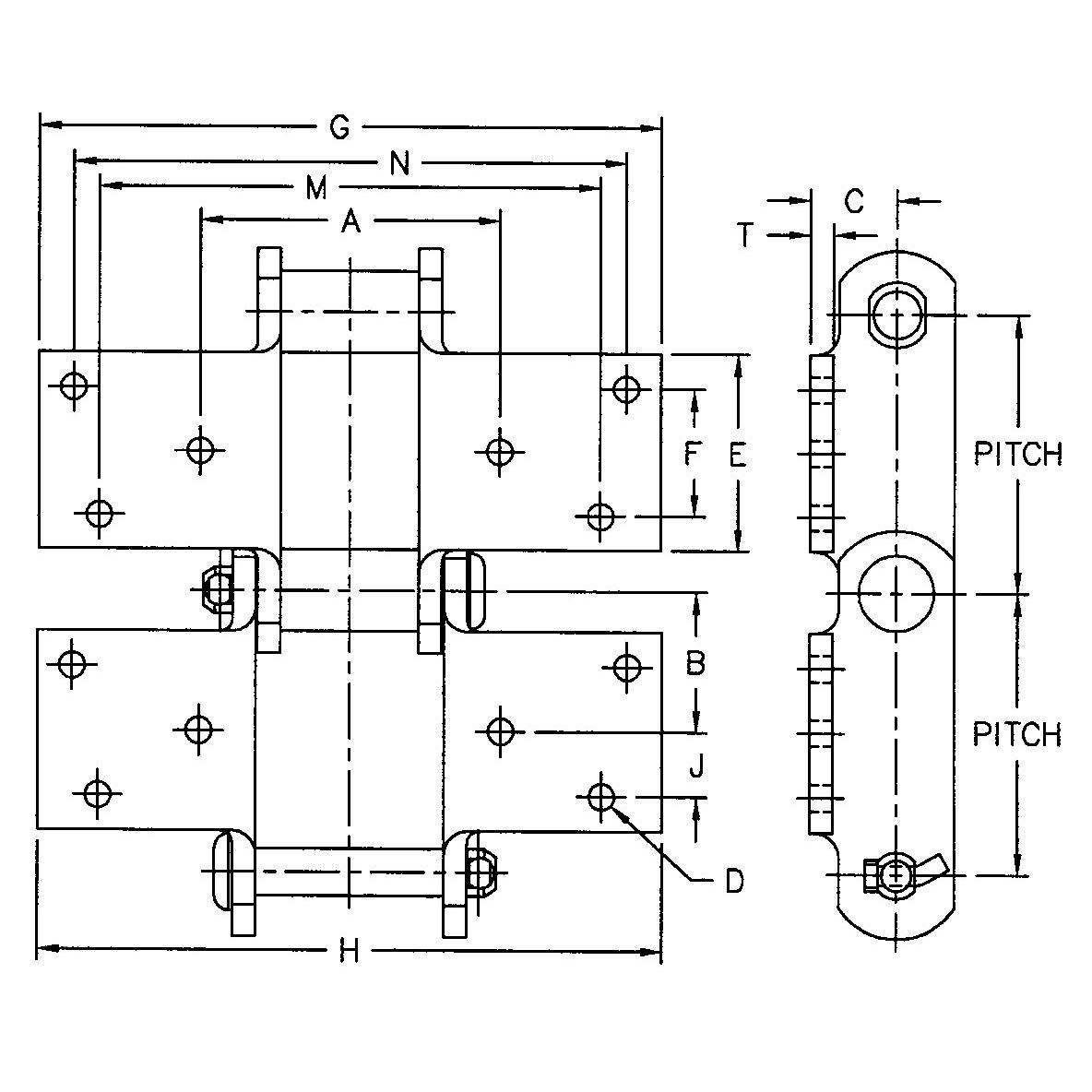

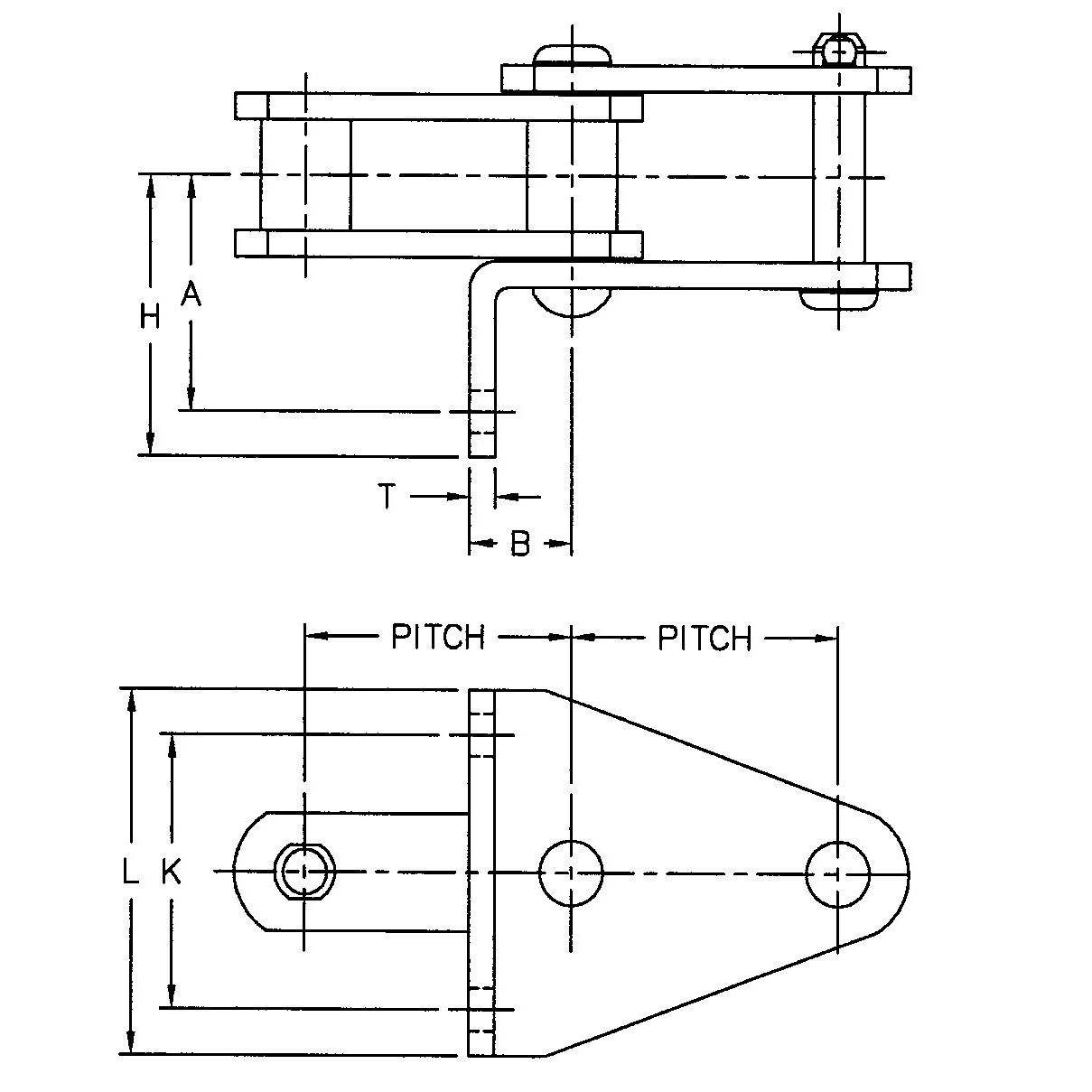

Bushed and taper lock sprockets are essential components in power transmission systems, widely used in various industrial applications. These sprockets are designed to securely connect to shafts, ensuring efficient torque transmission and reliable operation. The bushed type utilizes a removable bushing system, allowing for easy installation and replacement without damaging the sprocket or shaft. Taper lock sprockets feature a tapered bushing that creates a tight grip on the shaft through a keyway and locking mechanism, providing high torque capacity and minimal backlash. Both types are known for their durability, versatility, and cost-effectiveness, making them ideal for conveyors, agricultural machinery, and heavy-duty equipment.

Key Features and Benefits

-

Easy Installation and Removal: The bushing or taper lock design enables quick mounting and dismounting without special tools, reducing downtime.

-

High Torque Transmission: Engineered to handle heavy loads with precision, ensuring smooth power delivery.

-

Interchangeability: Standardized dimensions allow compatibility with various shaft sizes and types, enhancing flexibility.

-

Durability: Made from high-quality materials like carbon steel or stainless steel, resistant to wear and corrosion.

-

Cost-Effective Maintenance: Replaceable bushings extend the sprocket's lifespan, lowering long-term costs.

Product Parameters and Specifications

Our bushed and taper lock sprockets are available in multiple sizes and configurations to meet diverse industrial needs. Below is a detailed table of specifications:

|

Parameter

|

Bushed Sprocket

|

Taper Lock Sprocket

|

|

Bore Size Range

|

10mm to 100mm

|

12mm to 120mm

|

|

Number of Teeth

|

10 to 60

|

10 to 80

|

|

Pitch

|

0.25 inch to 2.5 inch

|

0.375 inch to 3.0 inch

|

|

Material

|

Carbon Steel, Heat-Treated

|

Stainless Steel or Carbon Steel

|

|

Max Torque Capacity

|

Up to 500 Nm

|

Up to 1000 Nm

|

|

Weight Range

|

0.5 kg to 15 kg

|

1 kg to 25 kg

|

|

Standards

|

ANSI, ISO

|

ANSI, ISO, DIN

|

Additionally, we offer customizations such as special coatings for corrosion resistance, hardened teeth for increased wear life, and various hub designs. All products undergo rigorous quality checks to ensure compliance with international standards.

Applications

Bushed and taper lock sprockets are versatile and used across numerous industries:

-

Conveyor Systems: For material handling in warehouses and production lines.

-

Agricultural Machinery: In tractors, combines, and irrigation systems.

-

Industrial Equipment: Including packaging machines, printing presses, and robotics.

-

Automotive: For timing drives and transmission systems.

-

Mining and Construction: In heavy-duty machinery like excavators and crushers.

FAQ: Common Questions About Bushed and Taper Lock Sprockets

What is the main difference between bushed and taper lock sprockets?

Bushed sprockets use a separate bushing that fits into the sprocket bore and onto the shaft, allowing for easy replacement. Taper lock sprockets incorporate a tapered bushing system that locks onto the shaft with a key and screws, providing a more secure fit for higher torque applications.

How do I install a taper lock sprocket correctly?

To install a taper lock sprocket, first clean the shaft and sprocket bore. Place the tapered bushing into the sprocket, align it with the shaft keyway, and slide it onto the shaft. Tighten the locking screws evenly in a crisscross pattern to ensure uniform pressure and a firm grip. Always refer to the manufacturer's torque specifications for the screws.

Can I reuse a bushed sprocket after replacing the bushing?

Yes, bushed sprockets are designed for reuse. Simply remove the worn bushing by loosening the set screws, and install a new bushing of the same size. This makes them cost-effective for maintenance, as only the bushing needs replacement instead of the entire sprocket.

What materials are these sprockets made from, and how does it affect performance?

They are typically made from carbon steel or stainless steel. Carbon steel offers high strength and is heat-treated for durability, suitable for most industrial environments. Stainless steel provides excellent corrosion resistance, ideal for wet or corrosive conditions. The material choice impacts weight, wear resistance, and lifespan.

How do I determine the right sprocket size for my application?

Consider factors such as shaft diameter, pitch of the chain, number of teeth required for speed ratio, and torque requirements. Use standard sizing charts based on ANSI or ISO standards, and consult with an engineer if needed to ensure compatibility with your system's specifications.

What maintenance is required for these sprockets?

Regular inspection for wear, proper lubrication of the chain and sprocket teeth, and checking tightness of locking screws for taper lock types. For bushed types, monitor bushing wear and replace as needed. Keep the system clean from debris to prevent premature failure.

Are these sprockets interchangeable between different brands?

Yes, if they adhere to common standards like ANSI or ISO, bushed and taper lock sprockets are generally interchangeable. However, always verify dimensions such as bore size, pitch, and hub configuration to ensure a perfect fit and avoid operational issues.

What is the typical lifespan of a bushed or taper lock sprocket?

Lifespan varies based on application, load, and maintenance. Under normal conditions with proper care, they can last several years. High-load or abrasive environments may reduce this, but regular maintenance and timely bushing replacements can extend longevity significantly.