DC Gear Motors

# DC Gear Motors: A Comprehensive Guide to Performance and Applications

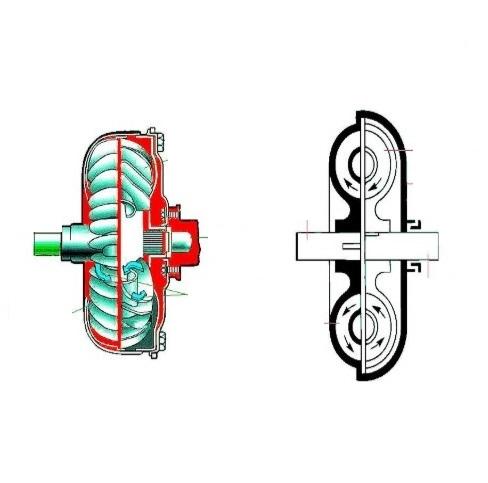

DC gear motors combine the efficiency of direct current motors with the torque-amplifying benefits of gear systems, making them indispensable in industries ranging from automotive to robotics. These motors are engineered to deliver high torque at low speeds, providing precise control and reliability in demanding applications. With over two decades of expertise in the field, we present a detailed overview of DC gear motors, covering their key parameters, specifications, and common queries to help you make informed decisions.

## Key Parameters of DC Gear Motors

Understanding the specifications of DC gear motors is crucial for selecting the right model for your needs. Below is a list of essential parameters:

- **Voltage Rating**: Typically ranges from 6V to 24V DC, influencing speed and torque output.

- **No-Load Speed**: Measured in RPM (revolutions per minute), indicating maximum speed without load.

- **Rated Load Speed**: The operational speed under specified load conditions.

- **Rated Torque**: Expressed in Nm (Newton-meters) or oz-in (ounce-inches), defining the motor's force output.

- **Gear Ratio**: The ratio of input to output speed, affecting torque multiplication (e.g., 10:1, 50:1).

- **Efficiency**: Percentage of electrical power converted to mechanical power, often between 70% and 90%.

- **Operating Temperature**: Range within which the motor functions optimally, usually -20°C to +85°C.

- **Noise Level**: Measured in decibels (dB), important for applications requiring quiet operation.

- **Life Expectancy**: Typically rated in hours of continuous operation, influenced by load and maintenance.

## Detailed Specifications Table

For a quick comparison, here is a table summarizing common DC gear motor models:

| Model Number | Voltage (V DC) | No-Load Speed (RPM) | Rated Load Speed (RPM) | Rated Torque (Nm) | Gear Ratio | Efficiency (%) | Operating Temperature (°C) | Noise Level (dB) | Life Expectancy (Hours) |

|--------------|----------------|---------------------|------------------------|-------------------|------------|----------------|----------------------------|------------------|-------------------------|

| GM-101 | 12 | 300 | 250 | 0.5 | 10:1 | 80 | -20 to +80 | 45 | 10,000 |

| GM-202 | 24 | 500 | 400 | 1.2 | 20:1 | 85 | -30 to +85 | 50 | 15,000 |

| GM-303 | 6 | 200 | 150 | 0.3 | 30:1 | 75 | -10 to +70 | 40 | 8,000 |

| GM-404 | 12 | 400 | 320 | 0.8 | 50:1 | 82 | -20 to +85 | 48 | 12,000 |

| GM-505 | 24 | 600 | 500 | 2.0 | 100:1 | 88 | -40 to +90 | 55 | 20,000 |

This table provides a snapshot of various models, but custom options are available to meet specific requirements.

## Applications of DC Gear Motors

DC gear motors are versatile and used in numerous sectors:

- **Automotive Industry**: Powering window regulators, seat adjusters, and windshield wipers.

- **Robotics**: Driving joints and movements in robotic arms and mobile robots.

- **Medical Devices**: Operating pumps, actuators, and diagnostic equipment with precision.

- **Industrial Automation**: Conveyor systems, packaging machinery, and valve controls.

- **Consumer Electronics**: DVD players, cameras, and home appliances like blenders.

Their ability to provide controlled, high-torque output makes them ideal for applications where space and weight are constraints.

## FAQ: Common Questions About DC Gear Motors

What is a DC gear motor?

A DC gear motor is an integrated unit consisting of a DC motor and a gearbox, designed to reduce speed and increase torque output for various mechanical applications.

How does the gear ratio affect performance?

The gear ratio determines the trade-off between speed and torque; a higher ratio (e.g., 50:1) increases torque but decreases speed, while a lower ratio (e.g., 10:1) offers higher speed with less torque.

What voltage should I choose for my application?

Select a voltage based on your power source and desired performance; higher voltages (e.g., 24V) generally provide more power and speed, but ensure compatibility with your system's electrical specifications.

Can DC gear motors be used in outdoor environments?

Yes, but it depends on the motor's IP (Ingress Protection) rating. Models with higher IP ratings (e.g., IP65) are sealed against dust and water, making them suitable for outdoor or harsh conditions.

How do I maintain a DC gear motor?

Regular maintenance includes checking for wear on gears, lubricating moving parts, and ensuring electrical connections are secure. Avoid overloading to extend the motor's lifespan.

What is the difference between brushed and brushless DC gear motors?

Brushed motors use physical brushes for commutation, offering simplicity and lower cost, while brushless motors use electronic controllers for higher efficiency, longer life, and less maintenance, but at a higher price point.

How do I calculate the torque required for my application?

Determine the load force, distance from the pivot point, and any friction factors. Use the formula Torque = Force × Distance, and select a motor with a rated torque exceeding this value for safety.

Are there custom options available for specific needs?

Yes, many manufacturers offer customization in voltage, gear ratio, shaft size, and mounting options to tailor the motor to unique application requirements.

What causes noise in DC gear motors, and how can it be reduced?

Noise can stem from gear meshing, bearing issues, or electromagnetic interference. Using quality lubricants, ensuring proper alignment, and selecting motors with lower noise ratings can minimize sound levels.

How long do DC gear motors typically last?

Lifespan varies based on usage, load, and environment; under rated conditions, they can last from 5,000 to 20,000 hours, but proper maintenance and avoiding overloads can extend this significantly.

Can I reverse the direction of a DC gear motor?

Yes, by reversing the polarity of the power supply, the motor's rotation direction can be changed, but ensure the gearbox is designed to handle bidirectional operation without damage.

What safety precautions should I take when installing a DC gear motor?

Always disconnect power before installation, secure the motor firmly to prevent vibration, and follow manufacturer guidelines for wiring and load limits to avoid electrical hazards or mechanical failure.

Are DC gear motors energy-efficient?

Yes, especially brushless models, which can achieve efficiencies up to 90%. Choosing the right gear ratio and voltage also optimizes energy consumption for your application.

How do temperature extremes affect performance?

Extreme cold can thicken lubricants and increase resistance, while extreme heat may cause overheating and reduced efficiency. Select motors with appropriate temperature ratings for your environment.

Where can I find technical support for DC gear motors?

Reputable manufacturers provide datasheets, application notes, and customer support teams to assist with selection, installation, and troubleshooting.