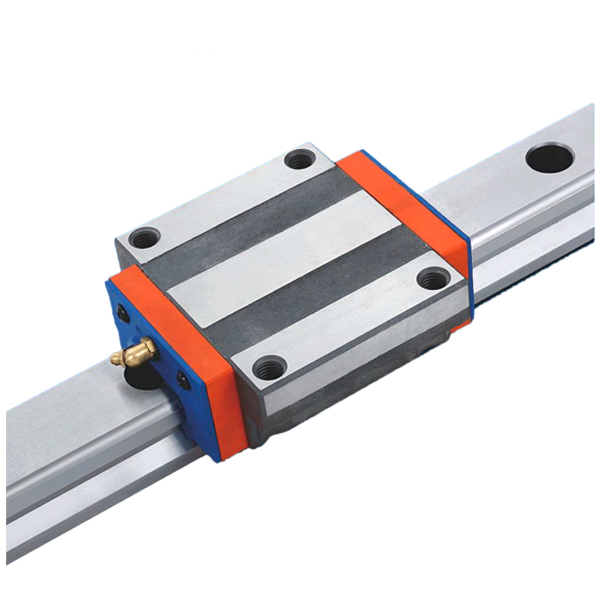

Linear Guideway: Precision Engineering for Industrial Applications

A linear guideway is an essential component in modern machinery, providing smooth and precise linear motion. It is widely used in CNC machines, robotics, semiconductor equipment, and automation systems. Our linear guideways are designed with high-quality materials and advanced manufacturing processes to ensure durability, accuracy, and long service life.

Key Features of Our Linear Guideways

- High load capacity: Supports heavy loads with minimal deformation.

- Low friction: Reduces energy consumption and wear.

- High precision: Ensures accurate positioning for critical applications.

- Corrosion resistance: Treated surfaces protect against harsh environments.

- Easy installation: Designed for quick and straightforward integration.

Product Specifications

| Model |

Load Capacity (kN) |

Precision Grade |

Material |

Operating Temperature Range (°C) |

| LG-100 |

10 |

P0 |

Carbon Steel |

-20 to 80 |

| LG-200 |

20 |

P2 |

Stainless Steel |

-30 to 100 |

| LG-300 |

30 |

P4 |

Alloy Steel |

-40 to 120 |

| LG-400 |

40 |

P5 |

Hardened Steel |

-50 to 150 |

Detailed Parameter List

- Width: 15mm to 100mm, depending on model.

- Length: Customizable up to 4000mm.

- Accuracy: From ±0.005mm to ±0.01mm.

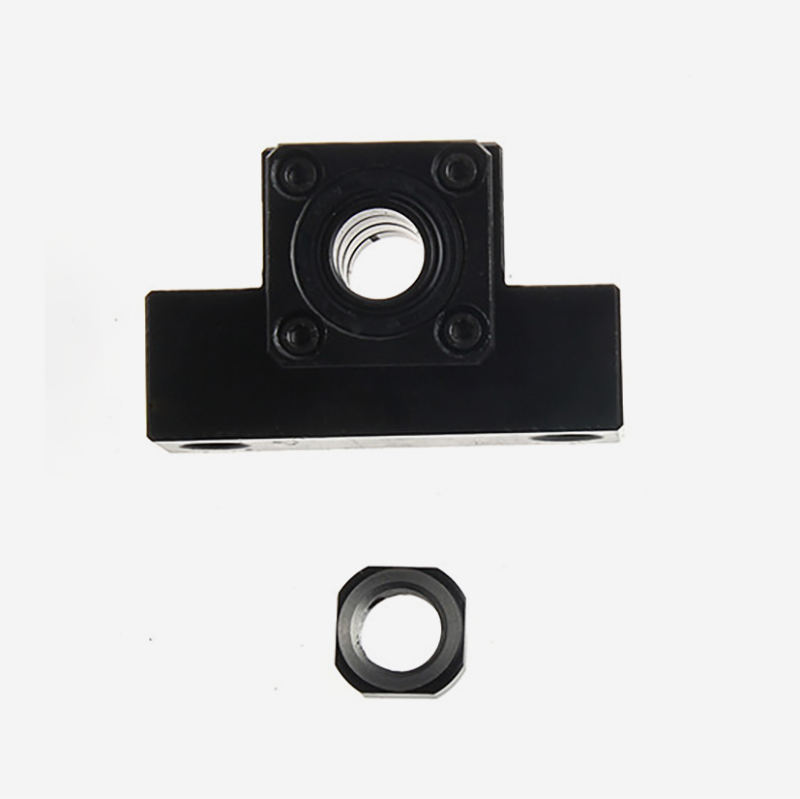

- Lubrication: Grease or oil options available.

- Mounting: Standard bolt patterns for easy attachment.

- Certifications: ISO 9001, CE, and RoHS compliant.

Linear Guideway FAQ

What is a linear guideway used for?

A linear guideway is used to provide smooth, precise linear motion in various industrial applications, such as CNC machining, robotics, and automated assembly lines. It reduces friction and ensures accurate positioning.

How do I choose the right linear guideway for my application?

Consider factors like load capacity, precision requirements, environmental conditions (e.g., temperature, humidity), and space constraints. Our product table above can help you compare models based on specifications.

What maintenance is required for a linear guideway?

Regular lubrication is essential to maintain performance. Inspect for wear and contamination periodically. Clean with appropriate solvents and relubricate according to the manufacturer's guidelines, typically every 6-12 months.

Can linear guideways be used in high-temperature environments?

Yes, certain models like the LG-300 and LG-400 are designed for high-temperature operations up to 150°C. Always check the operating temperature range in the specifications before selection.

What is the difference between precision grades P0, P2, P4, and P5?

Precision grades indicate the level of accuracy, with P0 being the standard and P5 offering the highest precision. Lower grades are suitable for general applications, while higher grades are for critical tasks like semiconductor manufacturing.

Are custom sizes available?

Yes, we offer customizable lengths and configurations to meet specific application needs. Contact our support team with your requirements for a tailored solution.

How do I install a linear guideway?

Installation involves aligning the guideway on a flat surface, securing it with bolts, and attaching the sliding block. Ensure proper alignment to avoid premature wear. Refer to the installation manual for step-by-step instructions.

What materials are used in your linear guideways?

We use high-quality materials such as carbon steel, stainless steel, alloy steel, and hardened steel, depending on the model. Each material offers different benefits in terms of strength, corrosion resistance, and durability.

Do you provide technical support?

Yes, our expert team offers technical support for selection, installation, and troubleshooting. Reach out via our contact page for assistance.

What is the typical lifespan of a linear guideway?

With proper maintenance, our linear guideways can last over 10 years under normal operating conditions. Lifespan may vary based on load, speed, and environment.