What Are Malleable Chains?

Malleable chains are highly durable, heat-treated iron chains known for their strength and flexibility. They are commonly used in various industrial, agricultural, and construction applications due to their ability to withstand heavy loads and harsh conditions. These chains are made from malleable cast iron, which provides a unique combination of toughness and ductility, making them less brittle than other types of chains. The manufacturing process involves casting and annealing, resulting in a product that can be bent or shaped to some extent without breaking, hence the name "malleable."

Key Features of Malleable Chains

- High tensile strength for heavy-duty use

- Excellent resistance to wear and abrasion

- Good malleability and impact resistance

- Corrosion-resistant options available with coatings

- Wide range of sizes and configurations to suit different needs

- Compliance with international safety standards (e.g., ISO 9001)

- Easy to install and maintain

- Suitable for both indoor and outdoor applications

Product Parameters and Specifications

Below is a detailed table outlining the standard parameters for our malleable chains. These specifications are based on common industry standards and can be customized upon request.

| Parameter |

Description |

Standard Value |

Units |

| Material |

Type of iron used |

Malleable Cast Iron |

- |

| Tensile Strength |

Maximum stress before breaking |

400-600 |

MPa |

| Chain Diameter |

Thickness of chain links |

6-20 |

mm |

| Working Load Limit |

Safe load capacity |

800-5000 |

kg |

| Length per Coil |

Standard length supplied |

5-30 |

meters |

| Weight per Meter |

Approximate weight |

0.5-5.0 |

kg/m |

| Surface Treatment |

Coating or finish |

Galvanized, Painted, or Plain |

- |

| Temperature Range |

Operational limits |

-20 to 200 |

°C |

| Standards Compliance |

Industry certifications |

ISO 9001, ASTM A47 |

- |

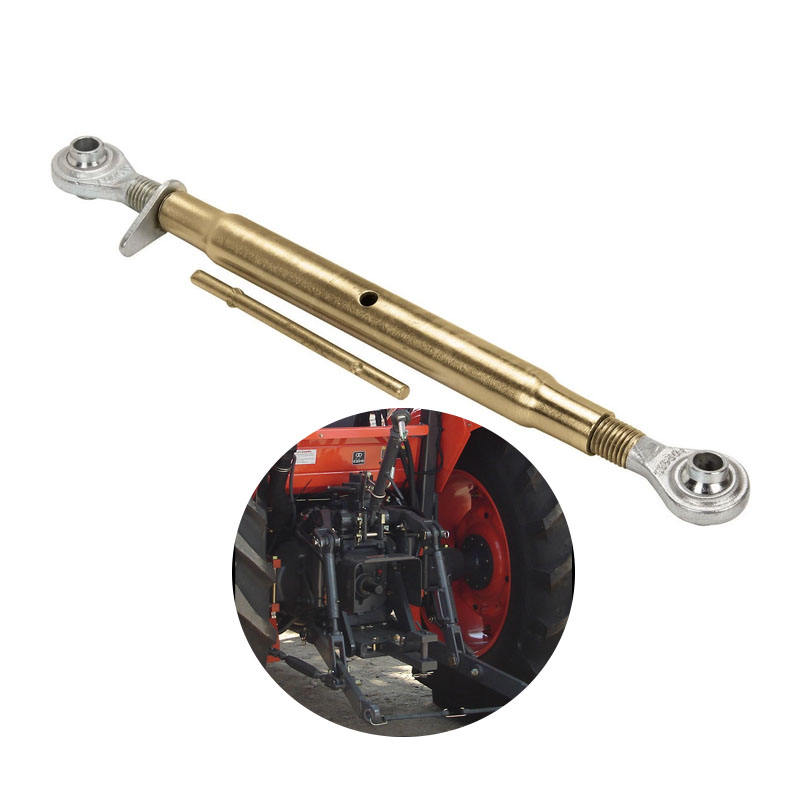

Applications of Malleable Chains

Malleable chains are versatile and used across multiple sectors. In agriculture, they are employed in machinery like tractors and combines for towing and lifting. In construction, they serve as safety chains, hoists, and barriers. Industrial uses include conveyor systems, logging, and marine applications due to their robustness. Their adaptability makes them ideal for temporary or permanent setups where reliability is crucial.

FAQ: Common Questions About Malleable Chains

What is the difference between malleable chains and wrought iron chains?

Malleable chains are made from cast iron that has been heat-treated to improve ductility, offering a balance of strength and flexibility. Wrought iron chains are forged and generally have higher ductility but may lack the same level of tensile strength for heavy loads.

How do I choose the right size of malleable chain for my application?

Consider the working load limit, chain diameter, and environmental conditions. Refer to the product specifications table and consult with a professional if unsure, as factors like dynamic loads or corrosion can affect performance.

Can malleable chains be used in corrosive environments?

Yes, but it is recommended to use galvanized or coated chains for enhanced corrosion resistance. Regular maintenance and inspections are advised to prolong lifespan in such conditions.

What is the average lifespan of a malleable chain?

Lifespan varies based on usage, load, and environment. With proper care and within specified limits, they can last several years. Inspect regularly for wear, deformation, or damage.

Are malleable chains recyclable?

Yes, malleable iron is recyclable. At end-of-life, chains can be melted down and reused, making them an environmentally friendly option compared to some alternatives.

Do you offer custom lengths or configurations?

Absolutely, we provide customization for length, coatings, and other parameters to meet specific project requirements. Contact our sales team for details.

How should I store malleable chains when not in use?

Store in a dry, cool place away from moisture and chemicals. Coiling them neatly prevents tangling and damage. Applying a light lubricant can help prevent rust.

What safety precautions should I take when using malleable chains?

Always adhere to the working load limit, avoid sudden shocks or overloads, and wear protective gear during handling. Regular inspections for cracks or wear are essential to prevent accidents.