Agricultural Chains: The Ultimate Guide to Durable and Efficient Farming Solutions

Agricultural chains are essential components in modern farming equipment, designed to withstand harsh conditions while ensuring optimal performance. These chains are used in various applications such as tractors, combines, balers, and other machinery, providing reliable power transmission and conveying. With advancements in materials and manufacturing, agricultural chains offer enhanced durability, resistance to wear, and minimal maintenance requirements. In this guide, we provide detailed product parameters, specifications, and answers to common questions to help you make informed decisions for your farming operations.

Key Product Parameters and Specifications

Our agricultural chains are engineered to meet high standards of quality and performance. Below are the main parameters categorized for clarity.

Material Composition

- Steel Grade: High-carbon steel or alloy steel for superior strength and toughness.

- Heat Treatment: Quenched and tempered to achieve a hardness of 40-50 HRC, enhancing wear resistance.

- Surface Finish: Zinc-plated or painted to prevent corrosion and extend chain life.

- Tensile Strength: Ranges from 18,000 to 30,000 pounds, depending on chain size and type.

Dimensions and Sizes

| Chain Type |

Pitch (inches) |

Width (inches) |

Working Load Limit (lbs) |

Weight per Foot (lbs) |

| Standard Roller Chain |

0.5 - 2.5 |

0.25 - 1.0 |

2,000 - 20,000 |

0.5 - 5.0 |

| Heavy-Duty Chain |

1.0 - 3.0 |

0.5 - 1.5 |

10,000 - 30,000 |

2.0 - 8.0 |

| Conveyor Chain |

0.75 - 2.0 |

0.375 - 1.25 |

5,000 - 25,000 |

1.0 - 6.0 |

Performance Features

- Temperature Resistance: Operates effectively in temperatures from -40°F to 500°F.

- Lubrication: Pre-lubricated for reduced friction; recommended re-lubrication interval: every 100 hours of operation.

- Compatibility: Designed to fit major equipment brands like John Deere, Case IH, and New Holland.

- Warranty: Standard warranty period of 2 years or 2,000 hours of use, whichever comes first.

Applications of Agricultural Chains

Agricultural chains are versatile and used in multiple farming scenarios:

- Tractor PTO Drives: Transmit power from the tractor to implements such as mowers and tillers.

- Harvesting Equipment: Integral to combines and forage harvesters for efficient crop gathering.

- Material Handling: Employed in conveyors for moving grain, feed, and other agricultural products.

- Balers and Presses: Ensure smooth operation in baling hay, straw, and other materials.

Frequently Asked Questions (FAQ)

What are the main types of agricultural chains available?

The primary types include roller chains, silent chains, leaf chains, and conveyor chains, each suited for specific applications like power transmission or material conveying.

How often should I lubricate my agricultural chain?

Lubrication frequency depends on usage intensity; generally, it's recommended to lubricate every 100 hours of operation or as per the manufacturer's guidelines to prevent wear and corrosion.

What factors affect the lifespan of an agricultural chain?

Key factors include proper tensioning, regular maintenance, environmental conditions (e.g., exposure to dirt and moisture), and the quality of materials used in the chain's construction.

Can I replace a chain myself, or should I seek professional help?

While simple replacements can be done with basic tools and safety precautions, complex installations or adjustments may require professional assistance to ensure optimal performance and avoid equipment damage.

Are there specific chains for organic farming operations?

Yes, chains made from food-grade materials or with special coatings are available to meet organic farming standards, reducing contamination risks.

How do I choose the right chain size for my equipment?

Refer to your equipment's manual for specifications on pitch, width, and load capacity. If unsure, consult with a supplier or measure the existing chain accurately.

What are the signs that a chain needs replacement?

Common indicators include excessive stretching (beyond 3% of original length), visible wear on rollers or links, rust that cannot be removed, and unusual noises during operation.

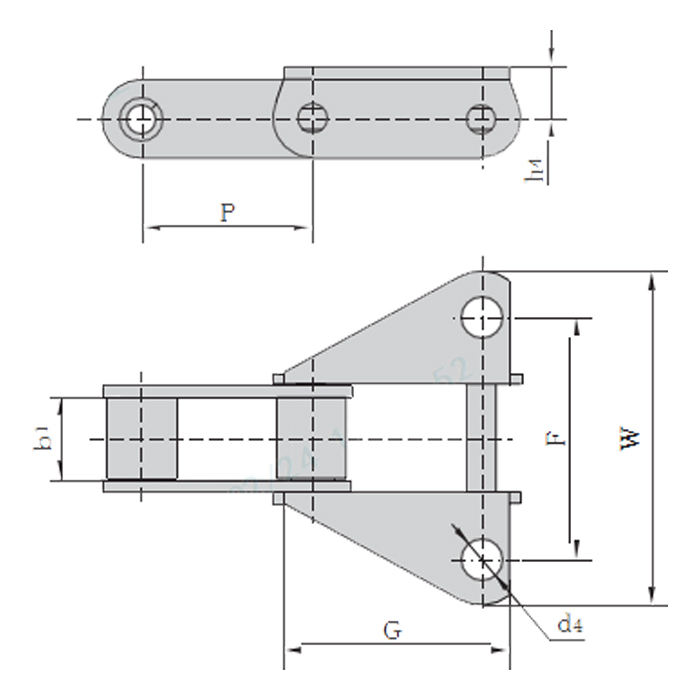

Do agricultural chains come with customization options?

Yes, many manufacturers offer custom lengths, attachments, and material choices to fit unique farming needs and machinery configurations.