A Comprehensive Guide to Gear & Racks: Specifications, FAQs, and More

Gear & racks are essential components in mechanical systems, providing precise motion control and power transmission in industries such as automotive, manufacturing, robotics, and aerospace. Our high-quality gear and rack products are engineered for durability, efficiency, and performance, meeting the stringent demands of modern applications. Below, we detail our product specifications, features, and answer common questions to help you make informed decisions.

Product Specifications and Features

Our gear and rack offerings include a wide range of types, materials, and sizes to suit various needs. Here are the key specifications presented in lists and tables for clarity.

Types of Gears We Offer

-

Spur Gears: Ideal for parallel shaft applications with high efficiency and simple design.

-

Helical Gears: Suitable for high-speed and high-load scenarios due to angled teeth reducing noise and vibration.

-

Bevel Gears: Used for intersecting shafts, commonly in differential systems.

-

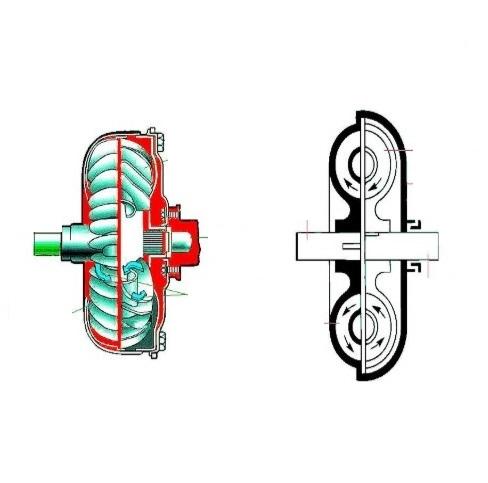

Worm Gears: Provide high reduction ratios and self-locking capabilities in compact spaces.

-

Rack and Pinion Sets: Convert rotational motion into linear motion, perfect for CNC machines and automotive steering.

Material Options

-

Steel Alloys: High strength and wear resistance, heat-treated for enhanced durability.

-

Stainless Steel: Corrosion-resistant, ideal for harsh environments like marine or food processing.

-

Brass and Bronze: Good for low-noise applications with moderate load capacity.

-

Plastic Polymers: Lightweight, cost-effective, and resistant to chemicals, suitable for light-duty uses.

Detailed Product Parameters Table

|

Product Type

|

Material

|

Module (mm)

|

Pressure Angle (degrees)

|

Load Capacity (N)

|

Operating Temperature Range (°C)

|

|

Spur Gear

|

Steel Alloy

|

1-10

|

20

|

Up to 5000

|

-40 to 120

|

|

Helical Gear

|

Stainless Steel

|

1.5-12

|

20

|

Up to 7000

|

-50 to 150

|

|

Bevel Gear

|

Brass

|

1-8

|

20

|

Up to 3000

|

-20 to 100

|

|

Worm Gear

|

Bronze

|

2-15

|

Various

|

Up to 10000

|

-30 to 200

|

|

Rack

|

Steel Alloy

|

1-10

|

20

|

Up to 6000 per linear meter

|

-40 to 120

|

Additional Features

-

Precision Machining: Tolerances within ±0.01mm for accurate performance.

-

Surface Treatments: Options include hardening, plating, and coating for extended lifespan.

-

Customization: Available in non-standard sizes and configurations upon request.

-

Compatibility: Designed to work with industry-standard components and systems.

Frequently Asked Questions (FAQ)

Here are some common questions and detailed answers to help you understand our gear and rack products better.

What factors should I consider when selecting a gear type?

Consider the application requirements, such as load capacity, speed, noise level, space constraints, and environmental conditions. For instance, spur gears are efficient for straightforward motions, while helical gears offer smoother operation at higher speeds.

How do I determine the appropriate material for my gear or rack?

Evaluate the operating environment: use steel alloys for high strength and wear, stainless steel for corrosion resistance, brass for noise reduction, and plastics for lightweight and chemical resistance. Always match the material to the load and temperature ranges.

What maintenance is required for gear and rack systems?

Regular lubrication is essential to reduce friction and wear. Inspect for signs of wear, misalignment, or damage periodically. For harsh environments, consider sealed or treated components to minimize maintenance needs.

Can you provide custom gear and rack solutions?

Yes, we offer customization services for unique specifications, including special sizes, materials, and tooth profiles. Provide your detailed requirements, and our engineering team will assist in designing a solution tailored to your needs.

How do I calculate the module for a gear system?

The module is calculated as the ratio of the pitch diameter to the number of teeth (Module = Pitch Diameter / Number of Teeth). It standardizes gear sizes and ensures compatibility; common modules range from 1 to 15 mm based on application demands.

What are the advantages of using a rack and pinion system?

Rack and pinion systems provide efficient linear motion conversion with high precision and reliability. They are compact, easy to install, and suitable for applications like CNC machinery, automotive steering, and automation systems where accurate positioning is critical.

How does temperature affect gear performance?

Extreme temperatures can cause expansion, contraction, or material degradation, leading to reduced efficiency or failure. Select materials with appropriate thermal properties and consider treatments like hardening to maintain performance within specified temperature ranges.

Are your products compatible with international standards?

Yes, our gears and racks are manufactured to meet ISO, AGMA, and DIN standards, ensuring interoperability and quality. Certifications and test reports are available upon request to verify compliance.

What is the typical lead time for orders?

Standard products ship within 1-2 weeks, while custom orders may take 3-6 weeks depending on complexity. We prioritize timely delivery and provide tracking information for all shipments.

How can I troubleshoot noise issues in a gear system?

Noise often stems from misalignment, improper lubrication, or wear. Check for correct installation, apply suitable lubricants, and inspect teeth for damage. Upgrading to helical gears or adding dampeners can also reduce noise in high-speed applications.