What Are Planetary Gears?

Planetary gears, also known as epicyclic gears, are a type of gear system that consists of a central sun gear, planet gears that rotate around the sun gear, and a ring gear that encloses the planet gears. This compact and efficient design is widely used in various industries due to its high torque density, smooth operation, and versatility in applications such as automotive transmissions, robotics, and industrial machinery. The unique arrangement allows for multiple gear ratios and high power transmission in a small package, making planetary gears ideal for space-constrained environments.

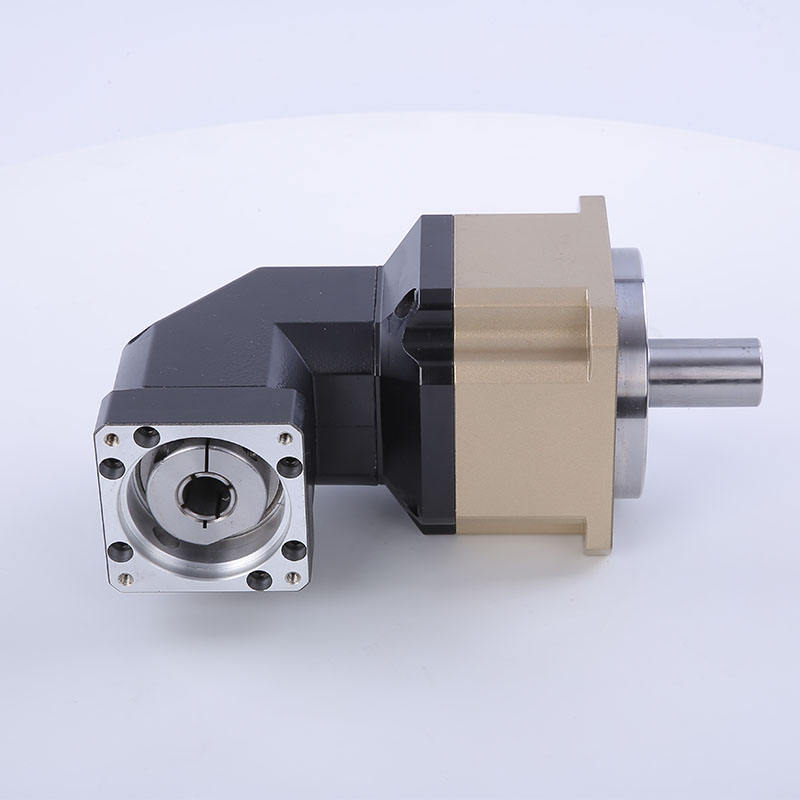

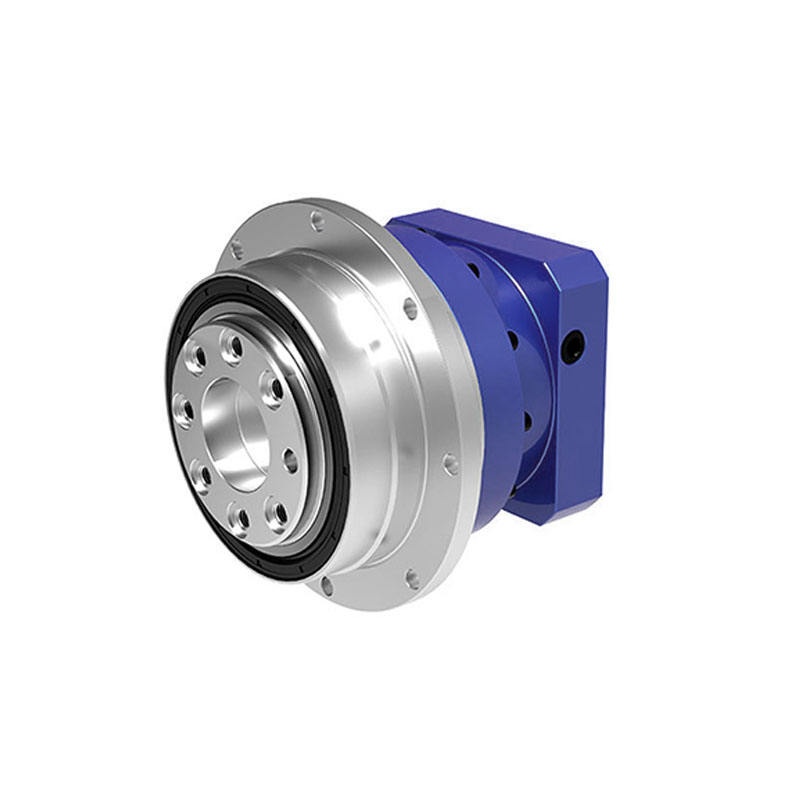

Key Features of Our Planetary Gears

- High torque capacity with minimal backlash for precise motion control.

- Compact and lightweight design, reducing overall system size and weight.

- Efficient power transmission with ratios up to 100:1, ensuring optimal performance.

- Durable construction using hardened steel or bronze materials for long service life.

- Low noise and vibration operation, suitable for sensitive applications.

- Customizable options available for specific torque, speed, and environmental requirements.

- Easy integration with motors and other drive components for seamless assembly.

- Maintenance-free operation in many cases, reducing downtime and costs.

Product Parameters and Specifications

Our planetary gears are engineered to meet rigorous industrial standards. Below is a detailed table of parameters for our standard product line. Customizations are available upon request to suit unique applications.

| Parameter |

Specification |

Units |

Notes |

| Gear Ratio Range |

3:1 to 100:1 |

Ratio |

Higher ratios available for custom orders |

| Rated Torque |

10 to 500 |

Nm |

Depends on size and material |

| Max Input Speed |

6000 |

RPM |

May vary with lubrication and load |

| Backlash |

< 5 |

arcmin |

Precision grades available |

| Efficiency |

95% to 98% |

Percentage |

Per stage, multi-stage efficiencies compound |

| Operating Temperature |

-40 to 120 |

°C |

With standard lubrication; special ranges possible |

| Material |

Steel, Bronze, or Aluminum |

N/A |

Coated options for corrosion resistance |

| Weight |

0.5 to 20 |

kg |

Varies by size and material selection |

| IP Rating |

IP65 standard |

N/A |

Higher ingress protection available |

Applications of Planetary Gears

Planetary gears are utilized in a wide array of industries due to their reliability and efficiency. Common applications include:

- Automotive: Transmissions, differential systems, and hybrid vehicle drives.

- Robotics: Joint actuators and precision movement systems.

- Aerospace: Landing gear mechanisms and control systems.

- Industrial Machinery: Conveyors, presses, and packaging equipment.

- Renewable Energy: Wind turbine gearboxes for power generation.

- Medical Devices: Surgical robots and imaging equipment.

- Marine: Propulsion systems and winches.

FAQ: Common Questions About Planetary Gears

What is the main advantage of using planetary gears over other gear types?

Planetary gears offer a high power-to-size ratio, meaning they can transmit more torque in a compact design compared to traditional gear systems. They also provide balanced load distribution among multiple planet gears, reducing wear and increasing durability.

How do I select the right planetary gear ratio for my application?

To choose the appropriate ratio, consider your input speed, desired output speed, and torque requirements. Calculate the ratio as output speed divided by input speed. For instance, if you need to reduce speed and increase torque, a higher ratio (e.g., 10:1) is suitable. Consult our technical team for personalized recommendations based on your specific setup.

Can planetary gears be used in high-temperature environments?

Yes, our planetary gears are designed to operate in temperatures from -40°C to 120°C with standard lubrication. For extreme conditions, we offer custom solutions with special materials and lubricants that can withstand higher temperatures up to 200°C or more.

What maintenance is required for planetary gears?

Most of our planetary gears are maintenance-free for their lifetime under normal operating conditions. However, periodic checks for lubrication levels and wear are recommended in high-load or continuous use applications. Use approved lubricants and follow the manufacturer's guidelines to ensure optimal performance.

Are custom planetary gears available for unique applications?

Absolutely. We provide custom design services to meet specific torque, size, ratio, and environmental needs. Whether you require unusual materials, special coatings, or unique mounting configurations, our engineering team can develop a solution tailored to your project.

How does backlash affect planetary gear performance?

Backlash refers to the slight movement between meshed gears when direction is reversed. Minimal backlash (<5 arcmin) is crucial for precision applications like robotics to ensure accurate positioning. Our gears are manufactured to tight tolerances to minimize backlash, with options for near-zero backlash upon request.

What materials are best for planetary gears in corrosive environments?

For corrosive environments, we recommend gears made from stainless steel or bronze with protective coatings such as nickel plating or zinc. These materials resist rust and degradation, ensuring longevity in harsh conditions like marine or chemical processing industries.

Can planetary gears be used in bidirectional operations?

Yes, planetary gears are designed for bidirectional operation, making them versatile for applications requiring forward and reverse motion. Ensure proper lubrication and load management to maintain efficiency and lifespan in both directions.