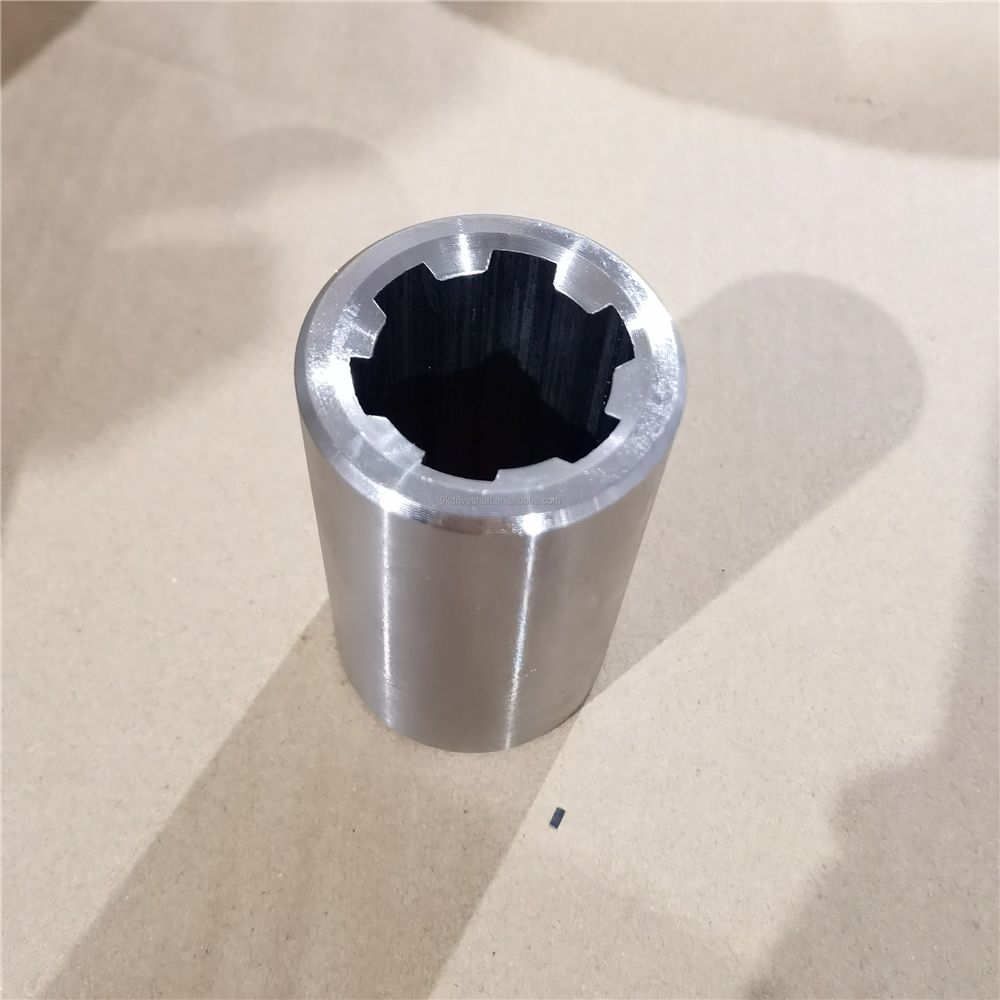

What Are Splined Hubs?

Splined hubs are precision-engineered mechanical components designed to transmit torque between shafts and mating parts, such as gears, couplings, or wheels. They feature a series of ridges or teeth (splines) on their inner or outer surface, allowing for secure engagement and efficient power transfer in various industrial and automotive applications. With their ability to handle high torque loads, reduce backlash, and accommodate misalignment, splined hubs are essential in systems requiring reliability and durability.

Key Features of Our Splined Hubs

- High-strength materials: Manufactured from alloy steel, stainless steel, or aluminum, ensuring durability and resistance to wear and corrosion.

- Precision machining: Each hub is CNC-machined to tight tolerances for optimal fit and performance.

- Customizable spline profiles: Available in involute, straight-sided, or serrated designs to meet specific application needs.

- Heat treatment options: Processes like carburizing or induction hardening enhance surface hardness and fatigue strength.

- Surface finishes: Options include plating, coating, or polishing to improve corrosion resistance and reduce friction.

- Lightweight designs: Aluminum variants offer reduced weight without compromising strength, ideal for aerospace or automotive uses.

- Easy installation: Designed with keyways, set screws, or flanges for simple integration into existing systems.

Product Parameters and Specifications

Our splined hubs come in a range of sizes and configurations to suit diverse industrial requirements. Below is a detailed table outlining standard parameters.

| Parameter |

Description |

Standard Values |

| Material |

Primary construction material |

Alloy Steel (e.g., 4140), Stainless Steel (e.g., 304/316), Aluminum (e.g., 6061) |

| Spline Type |

Profile design of the splines |

Involute, Straight-Sided, Serrated |

| Number of Splines |

Count of teeth or ridges |

10, 12, 24, 36, 48 (customizable) |

| Pitch Diameter |

Diameter at which splines engage |

20 mm to 200 mm (or 0.75" to 8") |

| Torque Capacity |

Maximum torque handling ability |

Up to 5000 Nm (dependent on size and material) |

| Hardness |

Surface hardness after treatment |

45-60 HRC for steel; 80-100 HB for aluminum |

| Temperature Range |

Operational temperature limits |

-40°C to 200°C (-40°F to 392°F) |

| Weight |

Approximate weight per unit |

0.5 kg to 20 kg (1.1 lbs to 44 lbs) |

| Standards Compliance |

Industry standards met |

ISO 4156, ANSI B92.1, DIN 5480 |

Applications of Splined Hubs

Splined hubs are versatile components used across multiple industries for efficient power transmission. Common applications include:

- Automotive systems: In transmissions, drive shafts, and steering mechanisms to handle high torque and vibration.

- Industrial machinery: For CNC machines, conveyor systems, and robotic arms where precision and reliability are critical.

- Aerospace: In landing gear, engine components, and control systems due to their lightweight and high-strength properties.

- Agricultural equipment: Used in tractors and harvesters to endure harsh environments and heavy loads.

- Marine applications: In propulsion systems and winches, offering corrosion resistance in saline conditions.

Frequently Asked Questions (FAQ)

What is the primary advantage of using a splined hub over a keyed shaft?

Splined hubs provide higher torque capacity, better distribution of load across multiple teeth, reduced stress concentration, and improved alignment compared to keyed shafts, which rely on a single keyway and are prone to loosening under high loads.

How do I select the right splined hub for my application?

Consider factors such as torque requirements, operating environment (e.g., temperature, exposure to chemicals), material compatibility, spline type (e.g., involute for smooth engagement), and size constraints. Consulting with an engineer or referring to industry standards like ISO 4156 can help ensure proper selection.

Can splined hubs be customized for specific needs?

Yes, we offer customization options including material choice, spline profile, number of teeth, diameter, surface treatment, and additional features like flanges or mounting holes. Provide detailed specifications for a tailored solution.

What maintenance is required for splined hubs?

Regular inspection for wear, corrosion, or damage is recommended. Lubrication may be necessary depending on the application to reduce friction and prevent seizing. In high-load environments, periodic replacement based on usage cycles helps maintain performance.

Are splined hubs compatible with international standards?

Our products are manufactured to meet global standards such as ISO 4156 (involute splines), ANSI B92.1 (American standards), and DIN 5480 (German standards), ensuring interoperability with components from different regions.

What is the typical lead time for ordering custom splined hubs?

Lead times vary based on complexity and quantity, but standard custom orders typically take 2-4 weeks for production and shipping. Rush services may be available for urgent requirements.

How do splined hubs handle misalignment in systems?

Certain spline designs, like involute splines, can accommodate minor angular and parallel misalignment due to their curved tooth profile, which allows for slight movement without compromising torque transmission or causing excessive wear.

What are the common failure modes of splined hubs, and how can they be prevented?

Common failures include wear from friction, fatigue cracking, and corrosion. Prevention measures include using appropriate materials (e.g., hardened steel for high wear), applying lubricants, ensuring proper installation alignment, and conducting routine maintenance checks.