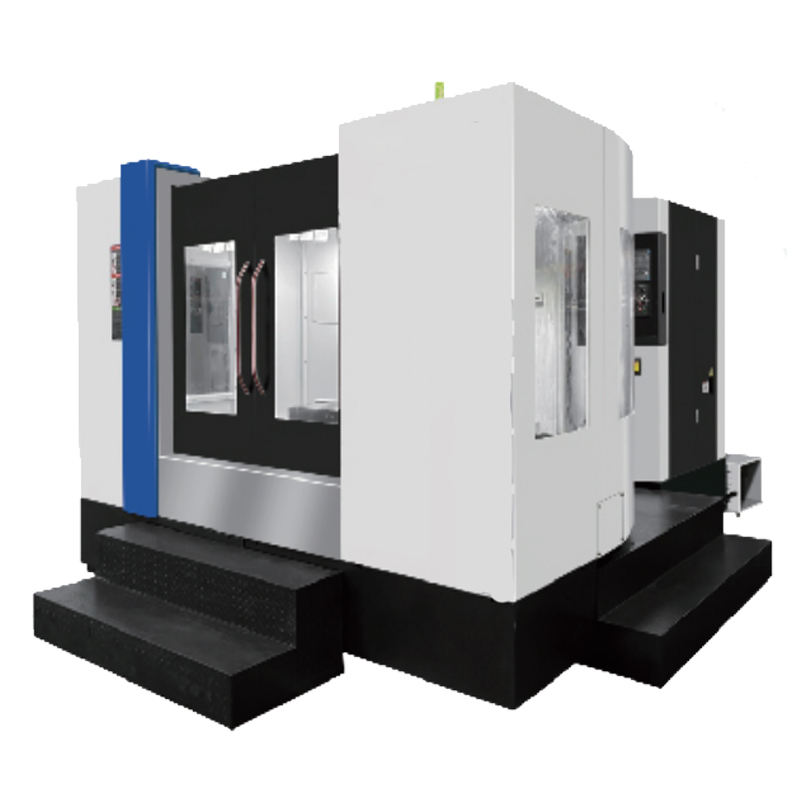

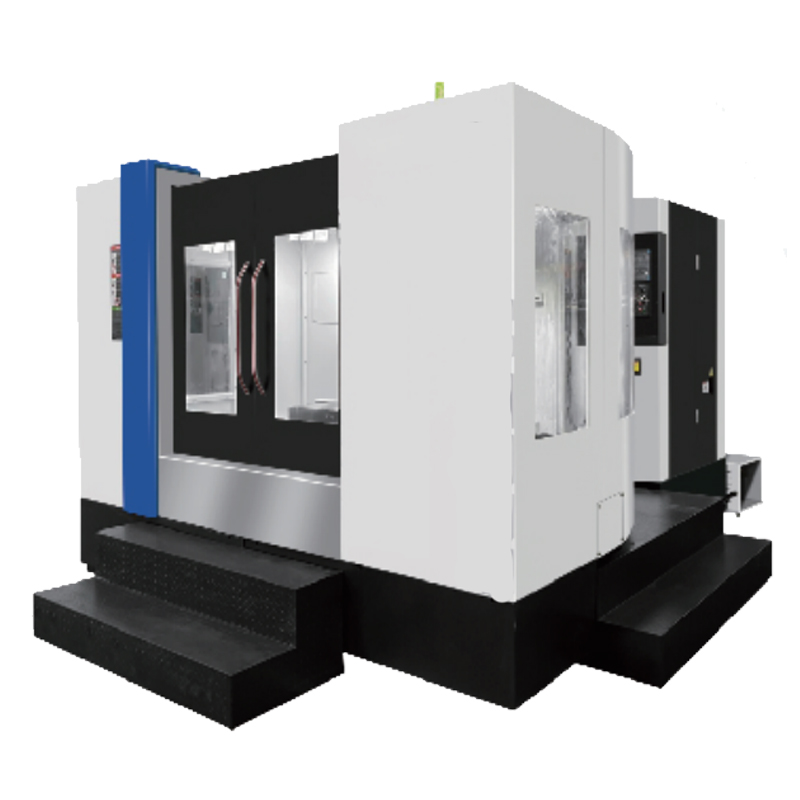

This series of machine tools adopts the internationally popular inverted T-shaped moving column integral bed structure, which has the advantages of high rigidity, good stability, and easy protection. The main castings are made of high-quality cast iron with high grade, resin sand molding, and secondary aging treatment after rough machining to ensure the stability of accuracy.

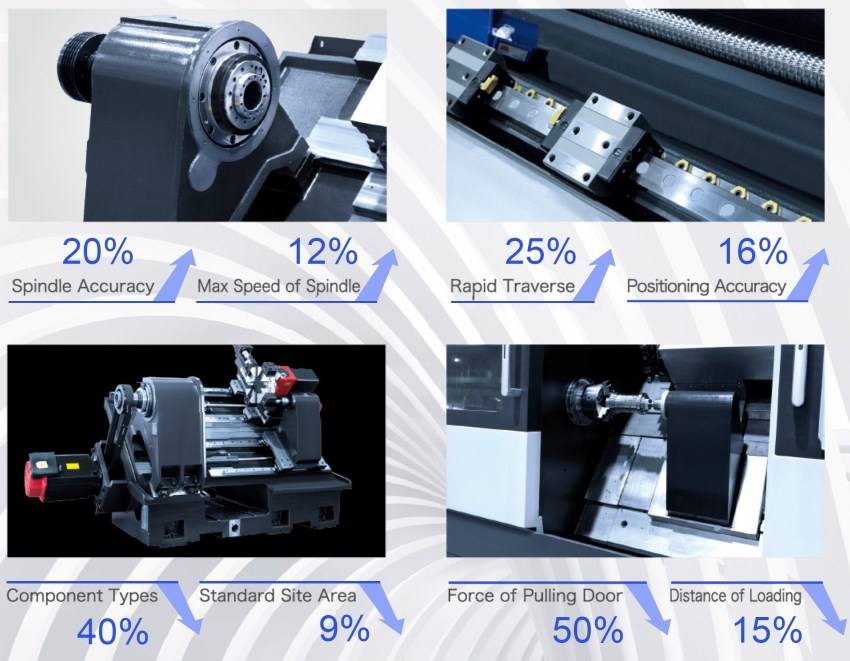

Good acceleration performance, suitable for efficient processing

Fully servo driven double tray exchange device, more stable

High indexing and positioning accuracy