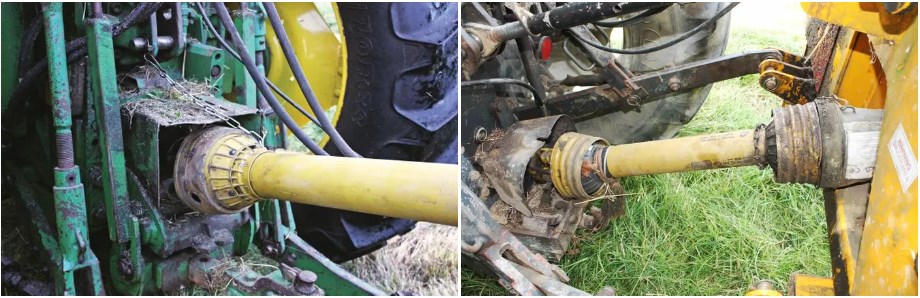

On compact tractors and their implements, the PTO shaft connection is not far from the ground. It may be easier to handle the PTO shaft connection on your knees. If you kneel on the proper ground, it will be faster to kneel and lift the weight of the implemented PTO shaft. When you hang the PTO shaft, the car floor mat, a carpet or some strong cardboard will reduce the pressure on your knees.

After the splines are aligned, press the locking pin button or pull the ball locking ring backward, and then push the shaft onto the PTO shaft. If it is difficult to slide, sometimes shaking the end of the implement PTO shaft up and down will help start.

After starting, slide the shaft – you may hear a click, the button should retract to the original position, otherwise the collar will slide forward. To ensure that the shaft lock is fully in place, pull the hand back from the button or collar to the shaft; It should not be possible to remove.

With these simple tips, you can reduce the time of PTO shaft connection and complete the work to be completed faster.

- Home

- About Us

- Products

- Sprockets

- Chains

- Gearboxes

- Worm Gearbox

- Planetary Gearbox

- Helical Gearbox

- Cycloidal Gear Reducer

- Shaft Mounted Gearbox

- Stainless Steel Worm Gearbox

- Car wash gearbox

- Greenhouse gearbox

- Poultry Feeding Gearbox

- Cement Polishing Gearbox

- Cement Mixer Gearbox

- Concrete Mixing Gearbox

- Helical Geared Motor with Brake

- Harmonic Drive

- Bevel Gearboxes

- Agricultural Gearbox

- Feed Mixer Gearbox

- Fertilizer Spreader Gearbox

- Flail Mower Gearbox

- Rotary Rake Gearboxes

- Lawn Mower Gearbox

- Post Hole Digger Gearbox

- Rotary Cutter Gearbox

- Rotary Mower Gearbox

- Rotary Tiller Gearbox

- Square Baler Gearbox

- Round Baler Gearbox

- Snowblower Gearbox

- Parallel Gearbox

- Micro Tiller Gearbox

- Manure Spreader Gearbox

- Irrigation Reels Gearbox

- Grain Transportation Gearbox

- Hydraulic Drive Gearbox

- PTO Generator Gearbox

- Gearbox for Hay Tedders

- Cutter Bars Gearbox

- Angular Gearbox

- Agricultural Sprayer Gearbox

- Agitators Gearbox for Sewage

- Drive Shaft

- Gear & Racks

- Screw Jacks

- V pulley & Sheaves

- Timing pulleys

- Top Link

- Couplings

- Hydraulic Cylinder

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- American Standard Series

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Motors

- Ball Screw

- Bushing & Hubs

- Shaft Collar

- Applications

- Cases

- News

- Download

- Send Inquiry

- Contact Us

Language