The HS6000 CNC Horizontal Machining Center is a type of advanced machining equipment used in industrial manufacturing processes. Here are some key features and applications of the HS6000 CNC Horizontal Machining Center:

Features:

1. CNC Control: The HS6000 is equipped with a Computer Numerical Control (CNC) system, which allows for precise control and automation of the machining operations. The CNC system enables high accuracy, repeatability, and flexibility in machining processes.

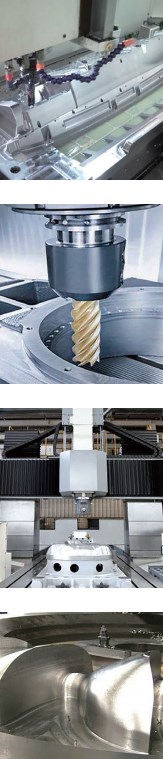

2. Horizontal Spindle Orientation: The HS6000 features a horizontal spindle orientation, which means that the spindle is positioned horizontally parallel to the worktable. This configuration offers advantages such as improved chip evacuation, enhanced tool life, and increased rigidity for heavy-duty cutting.

3. High Precision and Rigidity: The HS6000 is designed to provide high precision and rigidity during machining operations. It is built with robust construction and utilizes high-quality components to ensure stability, accuracy, and minimal vibration during cutting.

4. Multiple Axes: The HS6000 typically incorporates multiple axes, including X, Y, and Z axes, as well as additional rotary axes for multi-sided machining. This allows for complex part geometries and enables the machine to perform various operations, such as milling, drilling, tapping, and boring.

Applications:

1. Aerospace Industry: The HS6000 is commonly used in the aerospace industry for machining critical components, such as aircraft structural parts, engine components, landing gear parts, and turbine blades. Its high precision and rigidity make it suitable for machining complex shapes and materials used in aerospace applications.

2. Automotive Industry: The HS6000 finds applications in the automotive industry for producing engine blocks, cylinder heads, transmission components, and other critical parts. The machine's ability to handle heavy-duty cutting and its multi-axis capabilities are advantageous for machining automotive components with tight tolerances.

3. General Manufacturing: The HS6000 is utilized in general manufacturing processes where high precision and efficiency are required. It can be used for machining a wide range of materials, including metals, plastics, and composites, to produce components for various industries such as electronics, energy, medical, and more.

4. Mold and Die Industry: The HS6000 is suitable for the production of molds and dies used in plastic injection molding, die casting, and other forming processes. Its horizontal spindle orientation and multi-axis capabilities enable efficient machining of complex molds and dies with high precision and surface finish.

Overall, the HS6000 CNC Horizontal Machining Center is a versatile and high-performance machine that offers precision, rigidity, and multi-axis capabilities, making it well-suited for demanding machining applications in various industries.

- Home

- About Us

- Products

- Sprockets

- Chains

- Gearboxes

- Worm Gearbox

- Planetary Gearbox

- Helical Gearbox

- Cycloidal Gear Reducer

- Shaft Mounted Gearbox

- Stainless Steel Worm Gearbox

- Car wash gearbox

- Greenhouse gearbox

- Poultry Feeding Gearbox

- Cement Polishing Gearbox

- Cement Mixer Gearbox

- Concrete Mixing Gearbox

- Helical Geared Motor with Brake

- Harmonic Drive

- Bevel Gearboxes

- Agricultural Gearbox

- Feed Mixer Gearbox

- Fertilizer Spreader Gearbox

- Flail Mower Gearbox

- Rotary Rake Gearboxes

- Lawn Mower Gearbox

- Post Hole Digger Gearbox

- Rotary Cutter Gearbox

- Rotary Mower Gearbox

- Rotary Tiller Gearbox

- Square Baler Gearbox

- Round Baler Gearbox

- Snowblower Gearbox

- Parallel Gearbox

- Micro Tiller Gearbox

- Manure Spreader Gearbox

- Irrigation Reels Gearbox

- Grain Transportation Gearbox

- Hydraulic Drive Gearbox

- PTO Generator Gearbox

- Gearbox for Hay Tedders

- Cutter Bars Gearbox

- Angular Gearbox

- Agricultural Sprayer Gearbox

- Agitators Gearbox for Sewage

- Drive Shaft

- Gear & Racks

- Screw Jacks

- V pulley & Sheaves

- Timing pulleys

- Top Link

- Couplings

- Hydraulic Cylinder

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- American Standard Series

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Motors

- Ball Screw

- Bushing & Hubs

- Shaft Collar

- Applications

- Cases

- News

- Download

- Send Inquiry

- Contact Us

Language