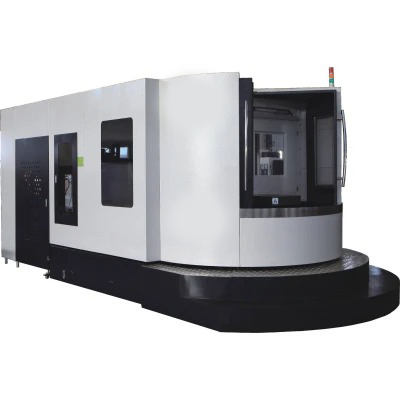

The SP1325 Double Column Machining Center offers several advantages and distinctive features that make it a versatile and efficient machine for various machining operations. Here are its key highlights:

1. Sturdy Double Column Design: The SP1325 features a robust double column structure, providing excellent stability and rigidity. This design ensures high precision and accuracy during heavy-duty machining tasks.

2. Large Working Area: With its generous working area, the SP1325 enables the machining of large workpieces and accommodates complex machining operations. It offers ample space for multiple setups and versatile workpiece handling.

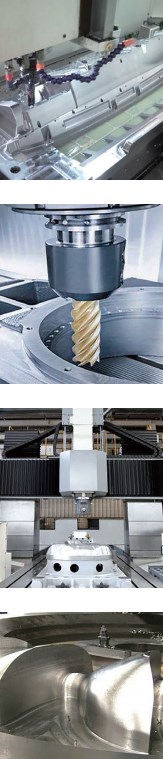

3. High-Speed and High-Power Spindle: Equipped with a high-speed and high-power spindle, the SP1325 delivers exceptional cutting performance and efficiency. It allows for fast material removal rates, reducing machining time and increasing productivity.

4. Advanced Control System: The machining center is equipped with an advanced control system that offers user-friendly operation and intuitive programming. It provides precise control over machining processes, ensuring accurate positioning and smooth operation.

5. Efficient Tool Changer: The SP1325 incorporates an automatic tool changer, enabling quick and seamless tool changes during machining operations. This feature minimizes downtime and increases productivity.

6. Versatile Machining Capabilities: The SP1325 supports a wide range of machining operations, including milling, drilling, tapping, and more. It is compatible with various materials such as metals, plastics, and composites, making it suitable for diverse manufacturing applications.

7. Enhanced Precision and Surface Finish: The SP1325 utilizes advanced technologies and components to achieve exceptional precision and surface finish. It ensures tight tolerances, smooth contours, and high-quality finishes, meeting the demanding requirements of modern machining.

8. Reliable Performance and Durability: Built with high-quality materials and components, the SP1325 offers reliable performance and long-term durability. It is designed to withstand heavy-duty operations and provide consistent results over extended periods of use.

- Home

- About Us

- Products

- Sprockets

- Chains

- Gearboxes

- Worm Gearbox

- Planetary Gearbox

- Helical Gearbox

- Cycloidal Gear Reducer

- Shaft Mounted Gearbox

- Stainless Steel Worm Gearbox

- Car wash gearbox

- Greenhouse gearbox

- Poultry Feeding Gearbox

- Cement Polishing Gearbox

- Cement Mixer Gearbox

- Concrete Mixing Gearbox

- Helical Geared Motor with Brake

- Harmonic Drive

- Bevel Gearboxes

- Agricultural Gearbox

- Feed Mixer Gearbox

- Fertilizer Spreader Gearbox

- Flail Mower Gearbox

- Rotary Rake Gearboxes

- Lawn Mower Gearbox

- Post Hole Digger Gearbox

- Rotary Cutter Gearbox

- Rotary Mower Gearbox

- Rotary Tiller Gearbox

- Square Baler Gearbox

- Round Baler Gearbox

- Snowblower Gearbox

- Parallel Gearbox

- Micro Tiller Gearbox

- Manure Spreader Gearbox

- Irrigation Reels Gearbox

- Grain Transportation Gearbox

- Hydraulic Drive Gearbox

- PTO Generator Gearbox

- Gearbox for Hay Tedders

- Cutter Bars Gearbox

- Angular Gearbox

- Agricultural Sprayer Gearbox

- Agitators Gearbox for Sewage

- Drive Shaft

- Gear & Racks

- Screw Jacks

- V pulley & Sheaves

- Timing pulleys

- Top Link

- Couplings

- Hydraulic Cylinder

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- American Standard Series

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Motors

- Ball Screw

- Bushing & Hubs

- Shaft Collar

- Applications

- Cases

- News

- Download

- Send Inquiry

- Contact Us

Language