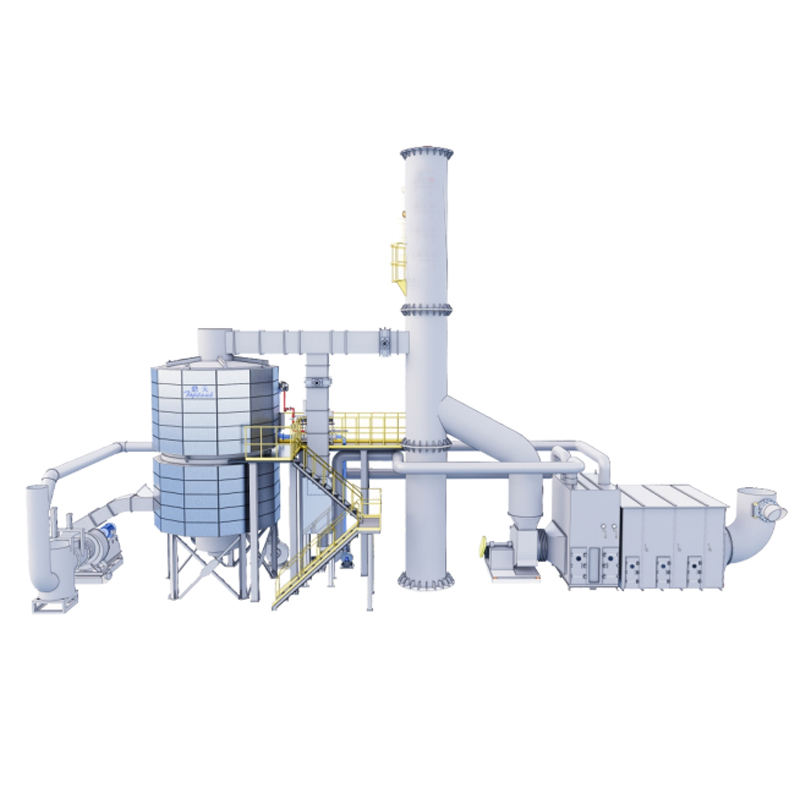

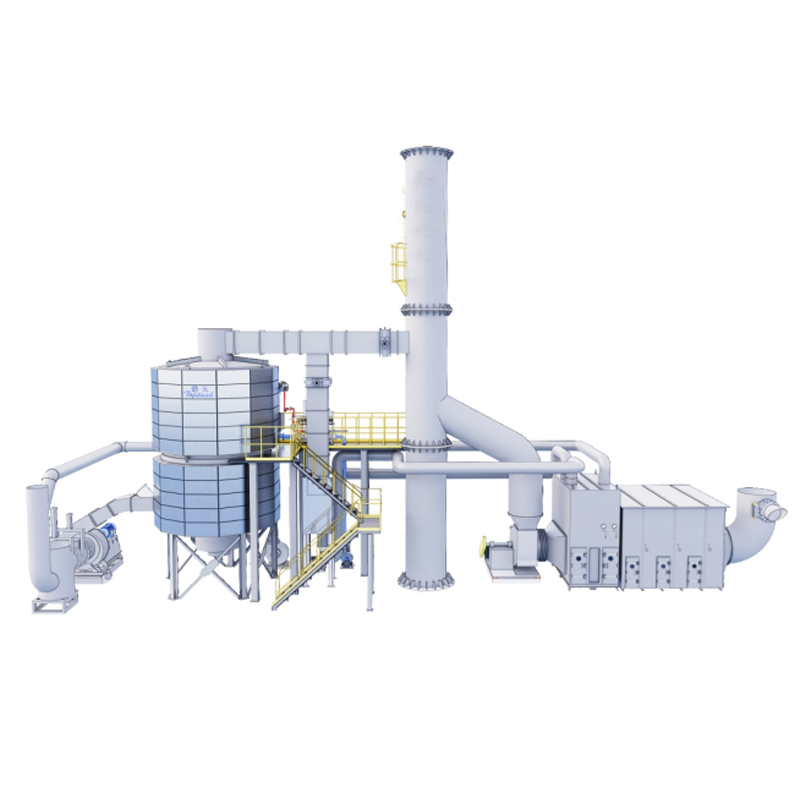

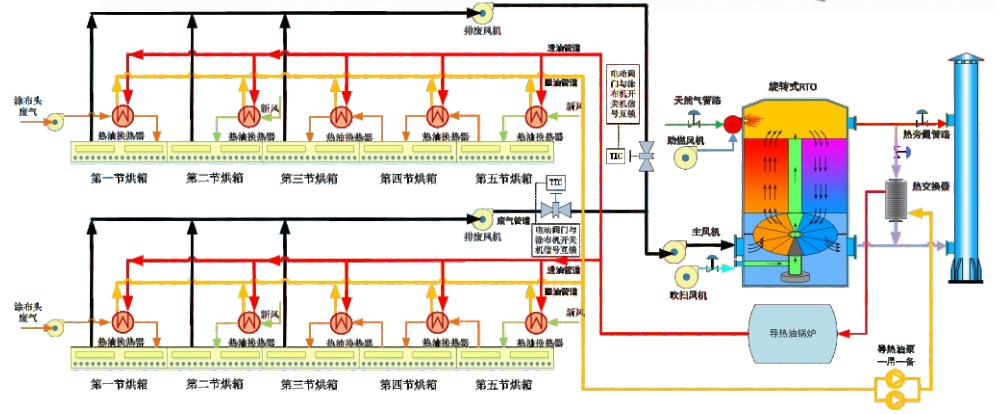

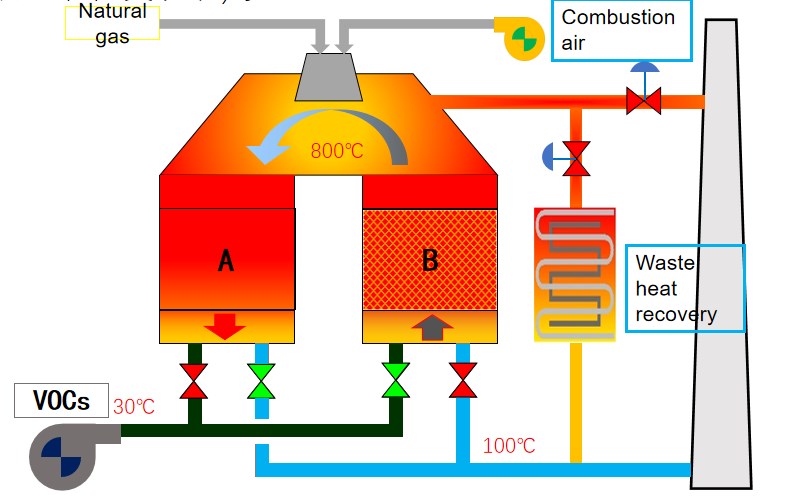

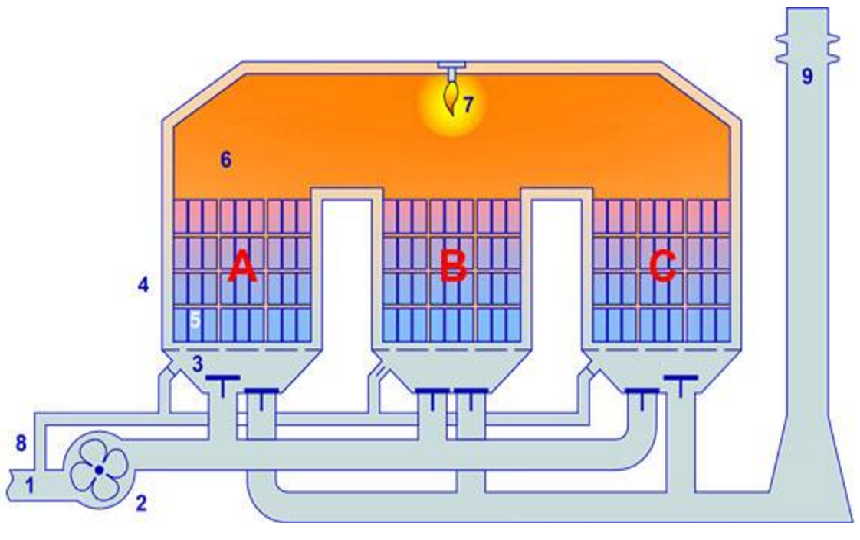

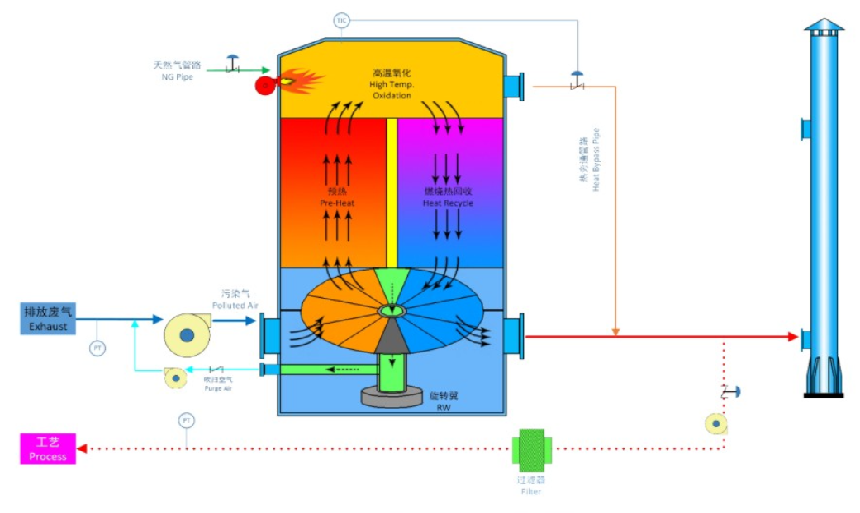

Using an RTO device to incinerate VOCS waste gas at high temperatures, achieving standard emissions. During the combustion of VOCS waste gas, a large amount of heat is released to maintain the reaction. When the concentration is high, waste heat recovery can also be carried out, achieving the goal of "environmental protection+energy conservation".

- Home

- About Us

- Products

- Sprockets

- Chains

- Gearboxes

- Worm Gearbox

- Planetary Gearbox

- Helical Gearbox

- Cycloidal Gear Reducer

- Shaft Mounted Gearbox

- Stainless Steel Worm Gearbox

- Car wash gearbox

- Greenhouse gearbox

- Poultry Feeding Gearbox

- Cement Polishing Gearbox

- Cement Mixer Gearbox

- Concrete Mixing Gearbox

- Helical Geared Motor with Brake

- Harmonic Drive

- Bevel Gearboxes

- Agricultural Gearbox

- Feed Mixer Gearbox

- Fertilizer Spreader Gearbox

- Flail Mower Gearbox

- Rotary Rake Gearboxes

- Lawn Mower Gearbox

- Post Hole Digger Gearbox

- Rotary Cutter Gearbox

- Rotary Mower Gearbox

- Rotary Tiller Gearbox

- Square Baler Gearbox

- Round Baler Gearbox

- Snowblower Gearbox

- Parallel Gearbox

- Micro Tiller Gearbox

- Manure Spreader Gearbox

- Irrigation Reels Gearbox

- Grain Transportation Gearbox

- Hydraulic Drive Gearbox

- PTO Generator Gearbox

- Gearbox for Hay Tedders

- Cutter Bars Gearbox

- Angular Gearbox

- Agricultural Sprayer Gearbox

- Agitators Gearbox for Sewage

- Drive Shaft

- Gear & Racks

- Screw Jacks

- V pulley & Sheaves

- Timing pulleys

- Top Link

- Couplings

- Hydraulic Cylinder

- Forklift Hydraulic Cylinders

- Agricultural Machinery Hydraulic Cylinders

- Aerial Work Vehicle Hydraulic Cylinders

- Sanitation Machinery Hydraulic Cylinders

- Construction Machinery Hydraulic Cylinders

- Mobile Machinery Hydraulic Cylinders

- American Standard Series

- Offshore Hydraulic Cylinders

- Energy Technology Hydraulic Cylinders

- Tunnel Boring Machine Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Industrial Engineering Hydraulic Cylinders

- Tractor & Front End Loader Hydraulic Cylinders

- Steering Hydraulic Cylinders

- Dump Truck & Trailer Hydraulic Cylinders

- Motors

- Ball Screw

- Bushing & Hubs

- Shaft Collar

- Applications

- Cases

- News

- Download

- Send Inquiry

- Contact Us

Language