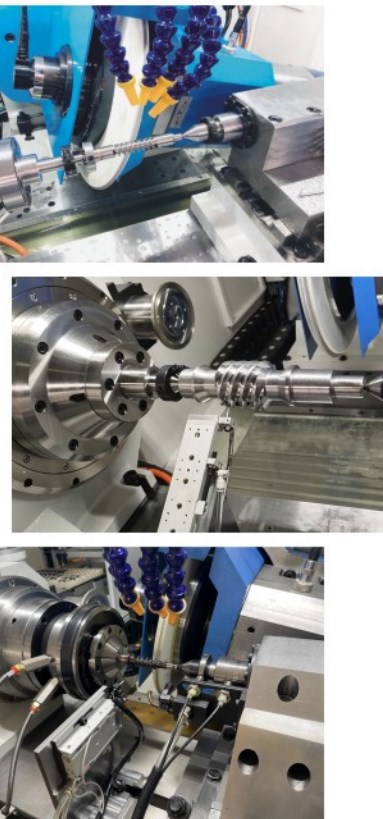

control. The thread grinding motion is completed by the linkage of a high rigidity and high torque torque torque motor (C-axis)

and a linear motor (Z-axis). The torque motor and linear motor simplify the transmission system, not only ensuring efficient

machining of forward and reverse continuous grinding, but also ensuring machining accuracy. The diamond roller is equipped with

dual axis interpolation and fully independently developed GPM modification software, Various tooth profiles of grinding wheels can

be adjusted online. The grinding wheel spindle adopts a high-power and high torque electric spindle imported from Germany and an

online dynamic balance control unit to ensure grinding efficiency and quality. This machine tool is not only suitable for single

head and multi head cylindrical worm gears with a thread elevation angle of up to 45 ° (ZA, ZN, Z1, ZK, ZC1), but also supports

double lead worm gear grinding and taper grinding.

Applicable scope Electric drive machine worm, reducer worm, double lead worm, high-precision threaded screw, C1 level screw,

circulating ball raceway screw, EPS worm, and various worm gears used in the automotive parts industry.