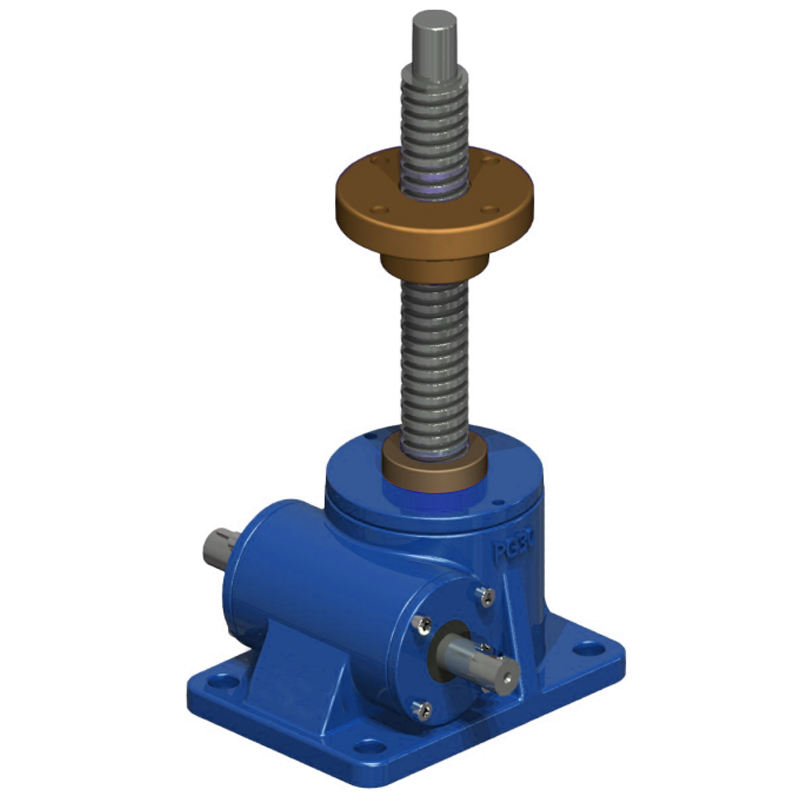

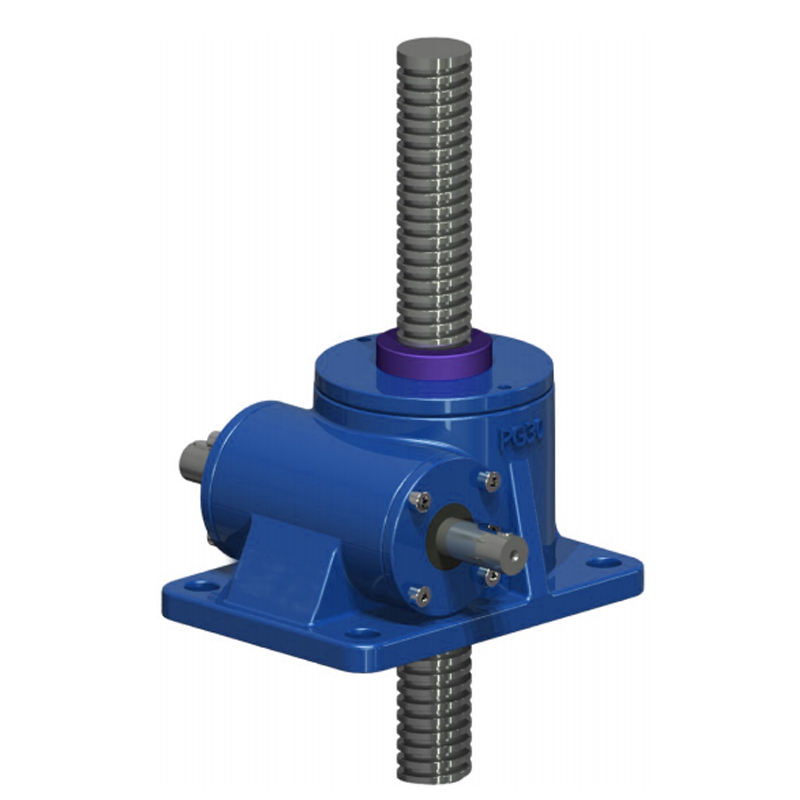

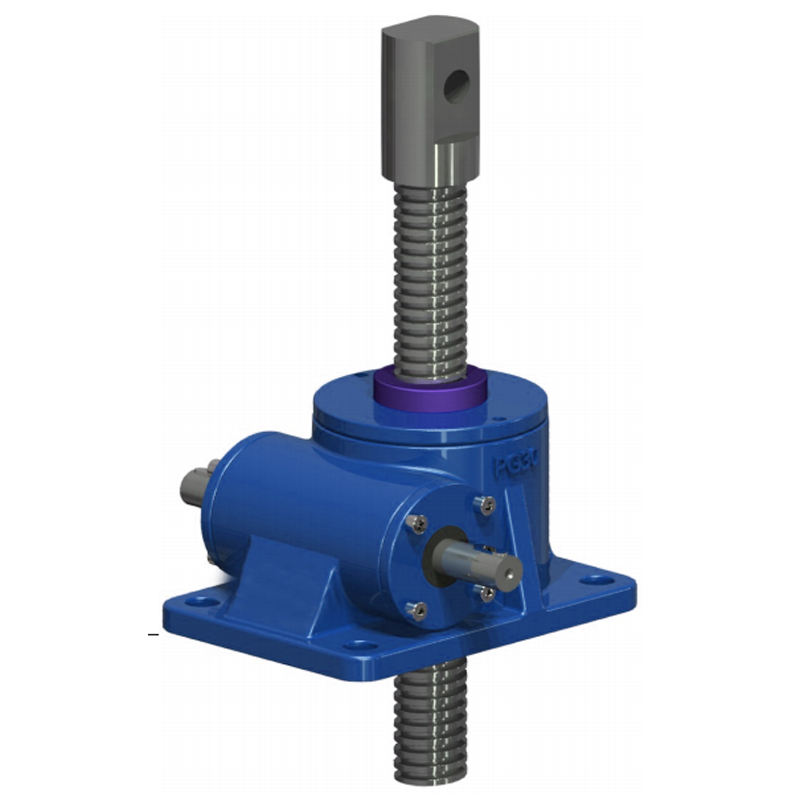

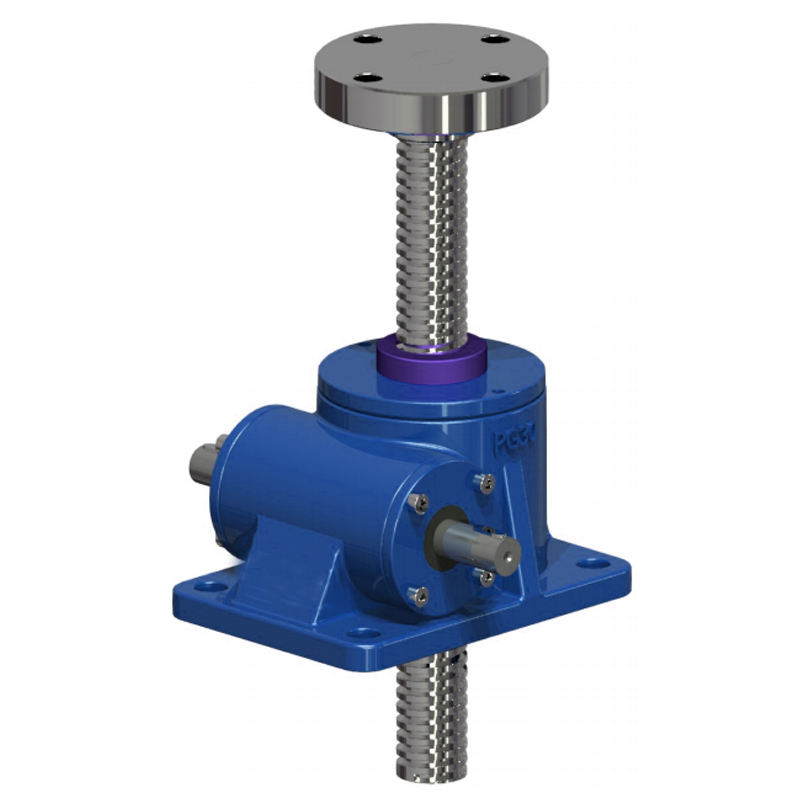

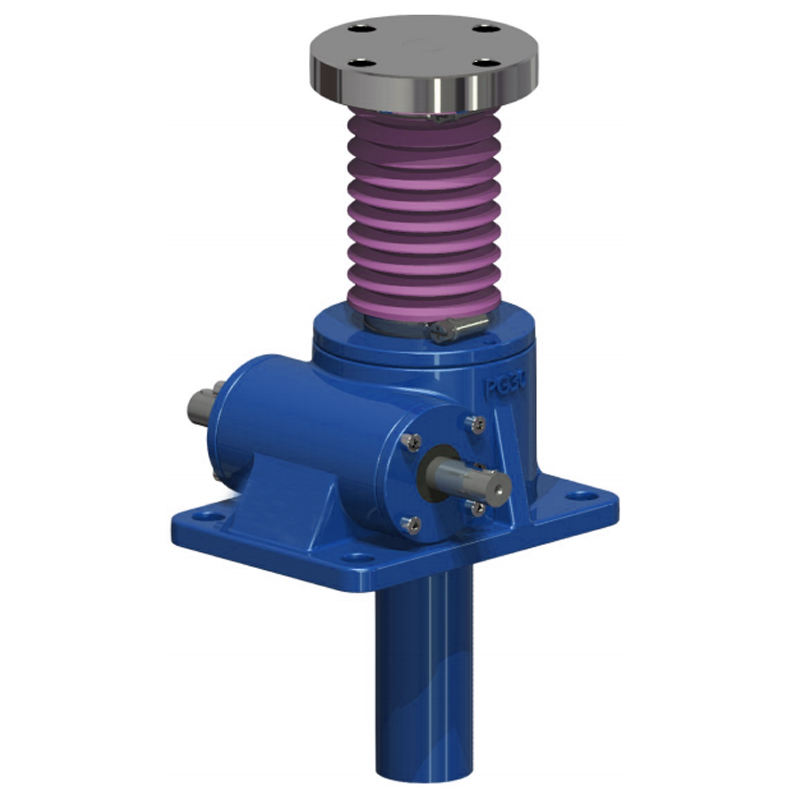

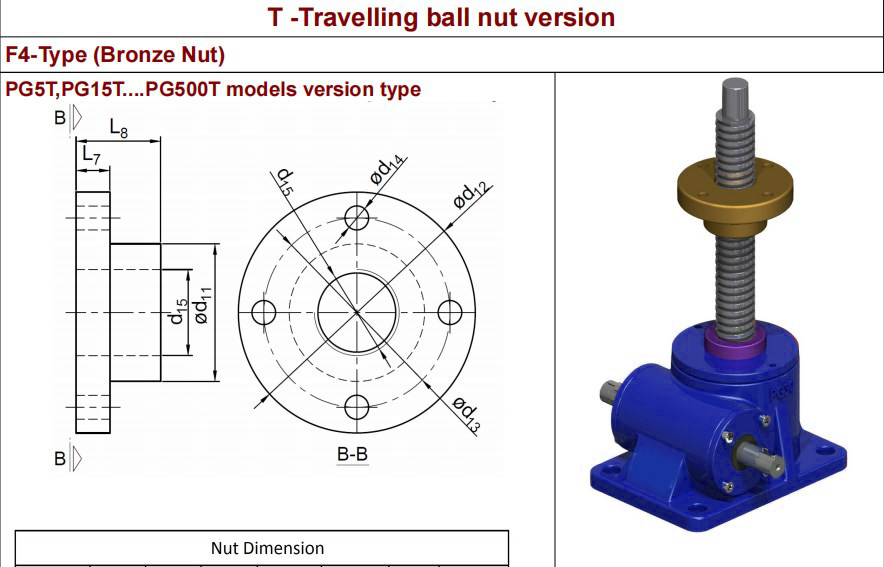

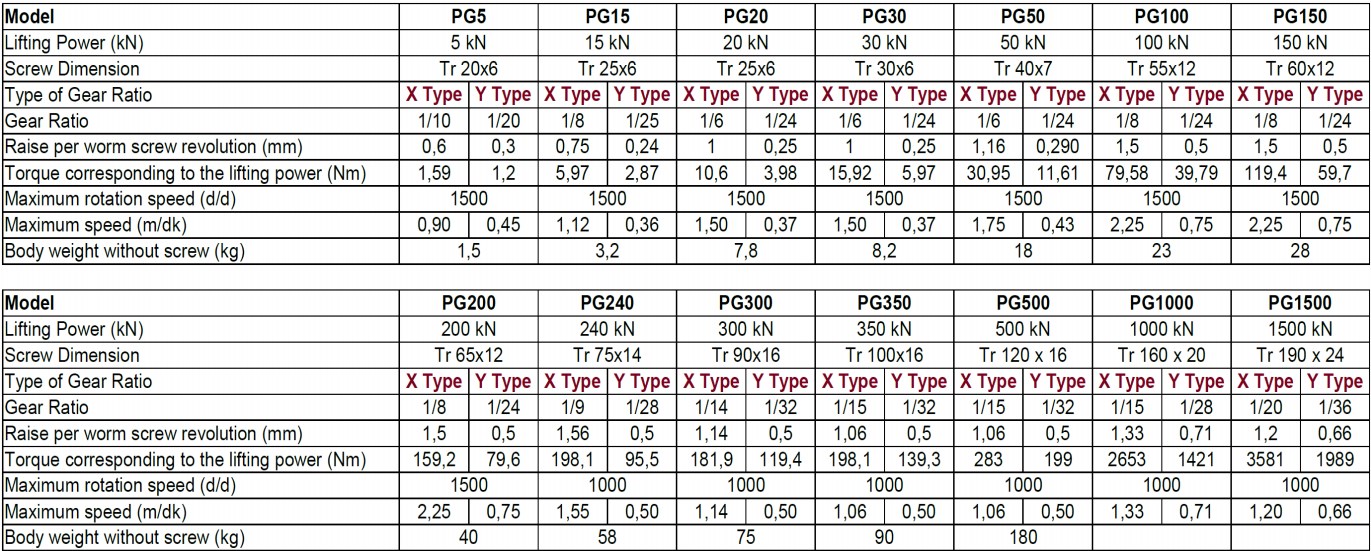

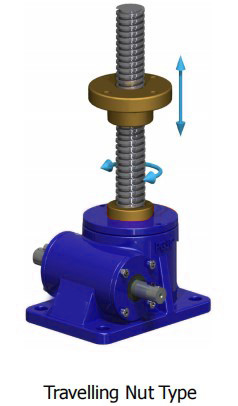

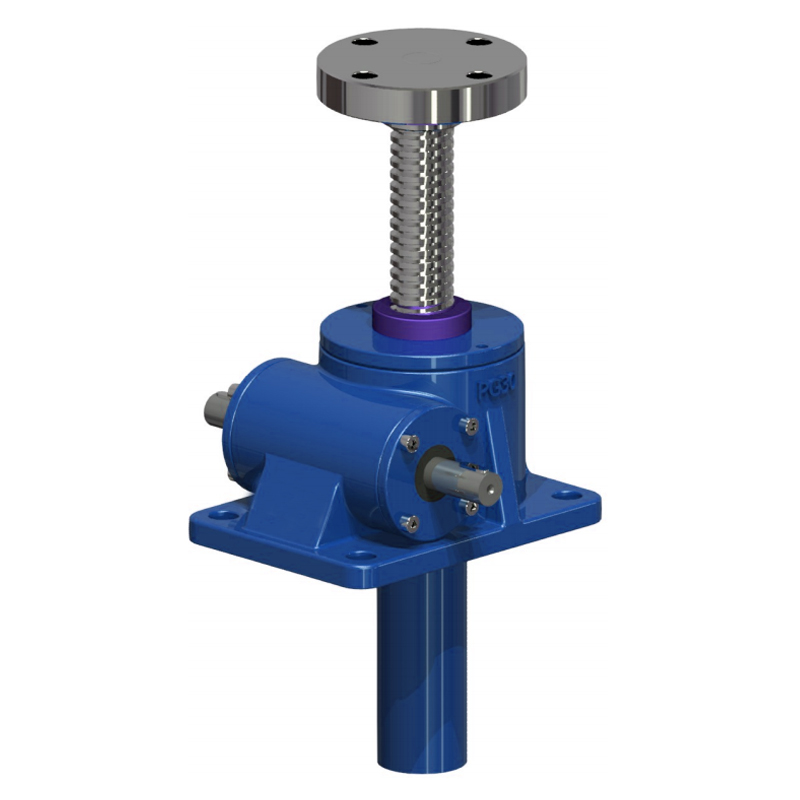

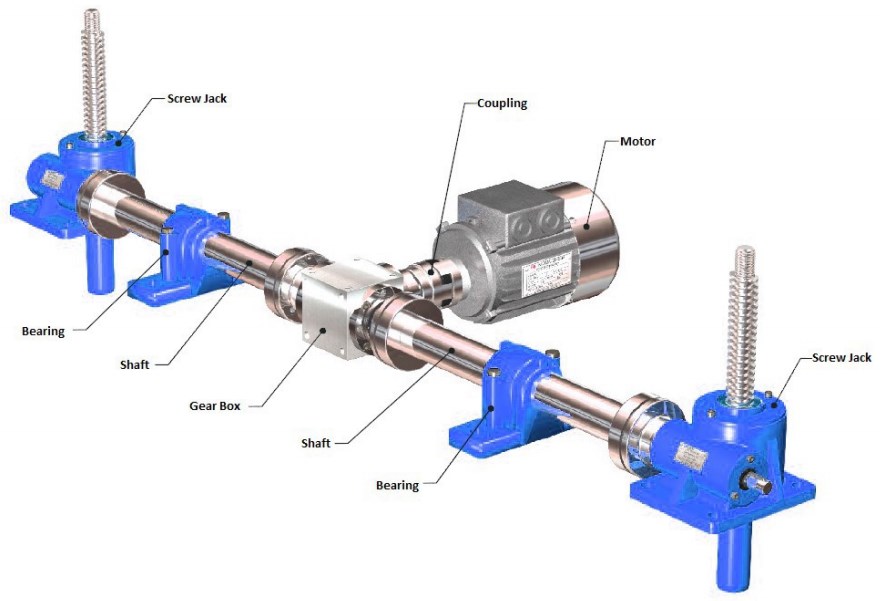

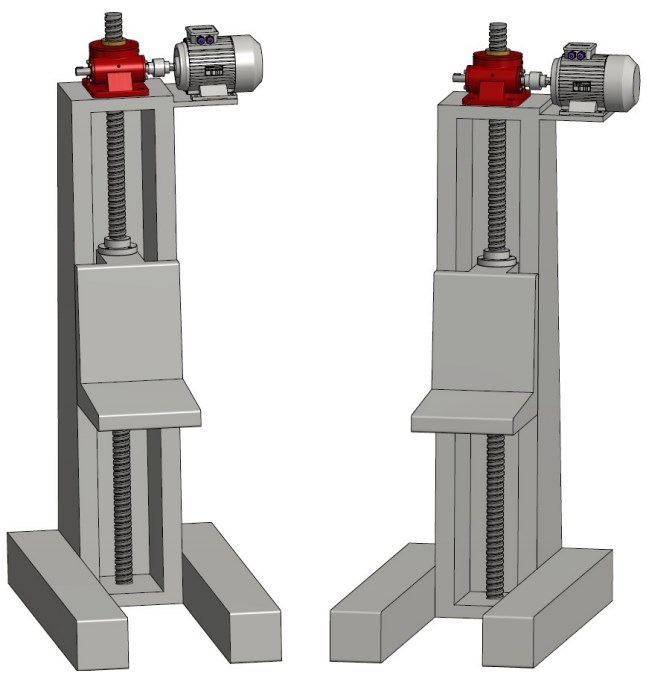

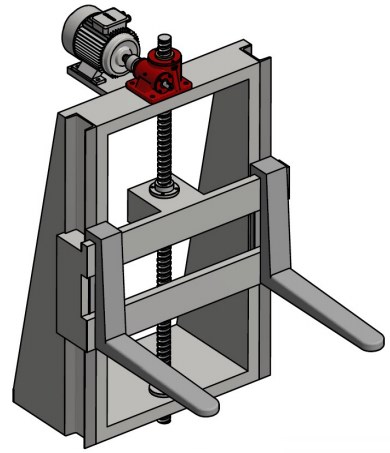

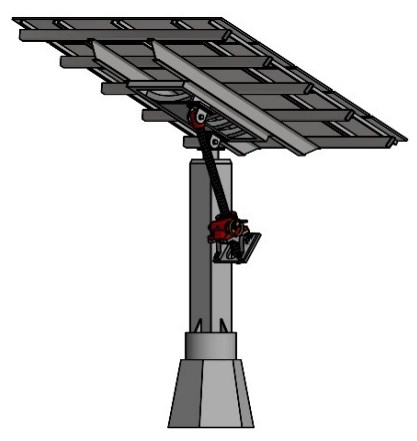

manually or by motor. With the rotation of the gear, the screw that is inside the screw jack only makes rotation around it's axis. The

flange, which is produced from the bronze material on the screw shaft moves linearly upwards or downwards. One of the purposes

of using such systems is the lack of ducting or storage for the movement of the screw used in the ball screw type and ball wedge screw type. Furthermore, the screw does not go beyond

the jack base. The linear motion of travelling nut depends on the turning speed, the number of teeth of the gears and the size of the screw pitch.